Vertical glass drilling machine

A drilling rig and glass technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve problems such as breakage, glass cannot be cooled, and drilling machine dust is difficult to clean, so as to save consumption, avoid polluting the processing environment, and save water. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

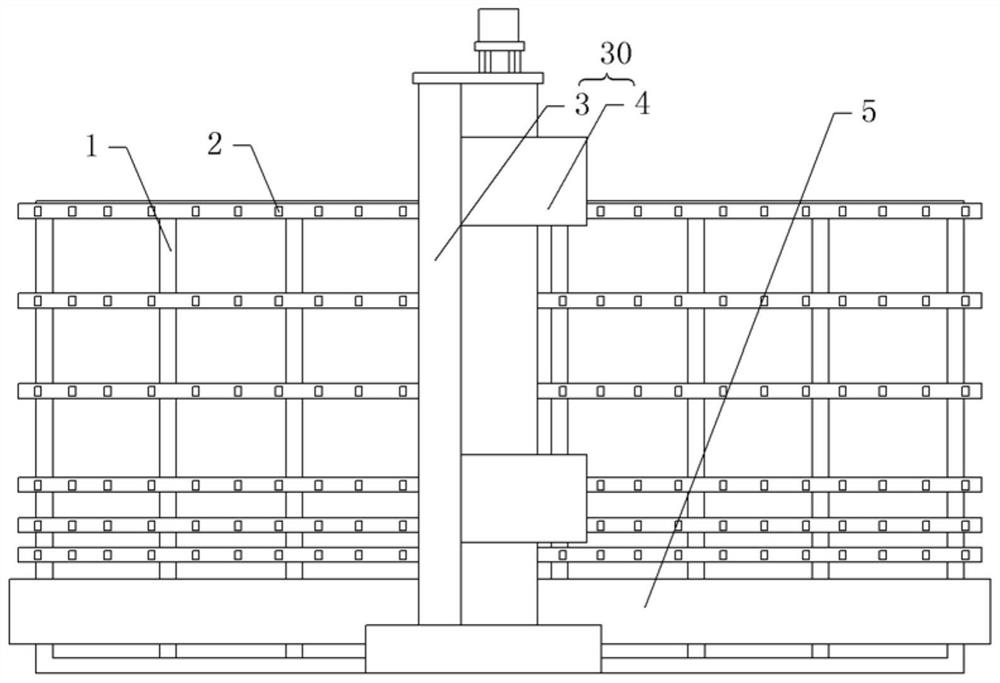

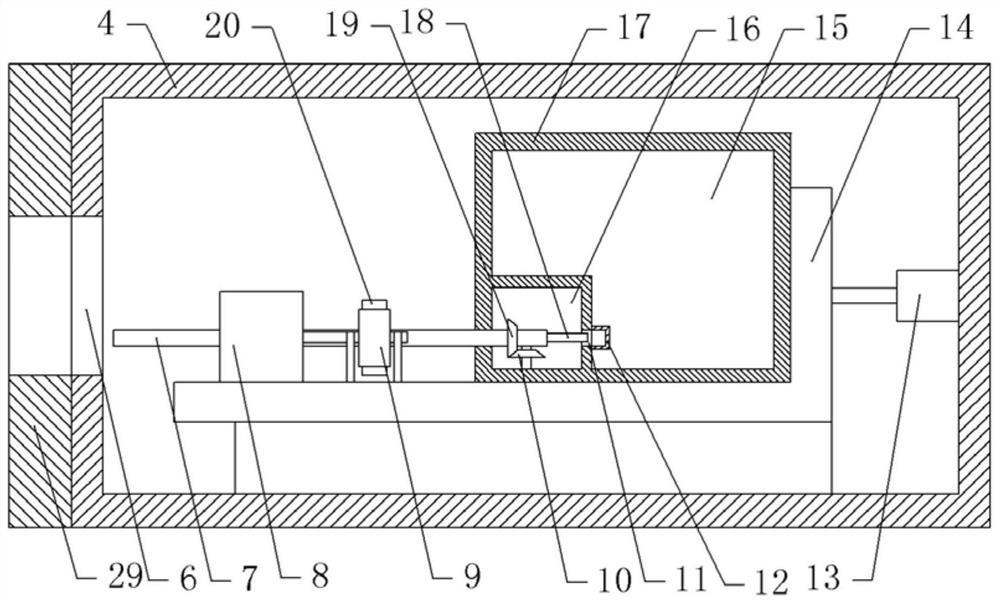

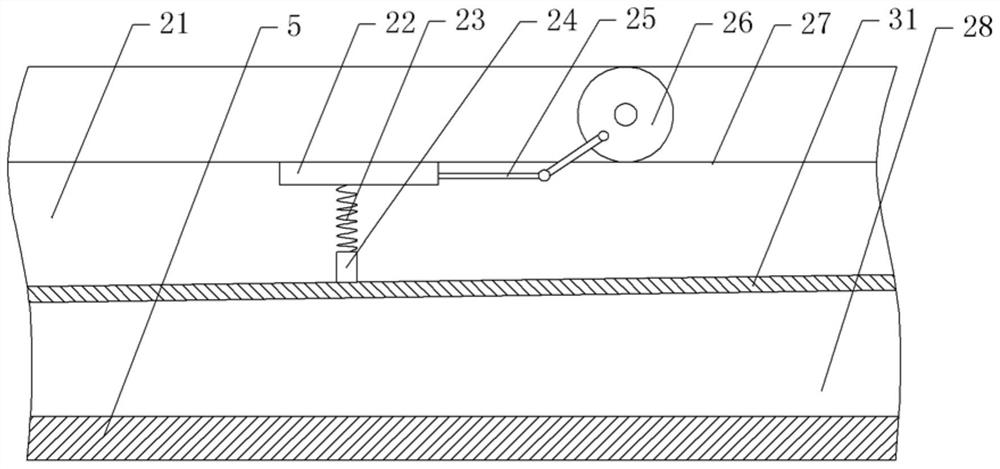

[0030] Such as Figure 1 to Figure 3 As shown, the glass vertical drilling machine includes a conveying mechanism and a drilling mechanism 30. The conveying mechanism includes a conveying frame 1 and a conveyor belt 27. The bottom of the conveying frame 1 is horizontally welded with a recovery box 5, and the conveyor belt 27 is installed in the recovery box 5. There is a gap in the middle part of the transport frame 1, and there are two drilling mechanisms 30, and the two drilling mechanisms 30 are respectively located on the front and rear sides of the gap. The conveying frame 1 is arranged inclined backwards as a whole, that is, the distance between the upper part of the conveying frame 1 and the drilling mechanism 30 is greater than that of the lower part thereof, so as to support the glass so that the glass can be vertically placed on the conveying frame 1. The two drilling mechanisms 30 are also arranged inclined backward as a whole, keeping parallel with the conveying fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com