Unmanned refueling system for underground explosion-proof vehicle

A technology of refueling system and oil supply system, which is applied in the direction of special distribution devices, packaging, distribution devices, etc., can solve the problems of insufficient intelligence, danger at the work site, and imperfect auxiliary systems, etc., and achieve high work efficiency and strong work continuity , Convenient and convenient working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this description, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

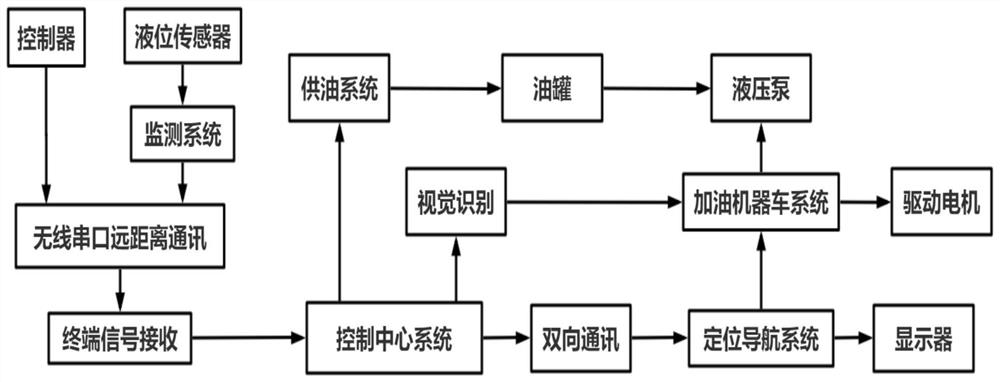

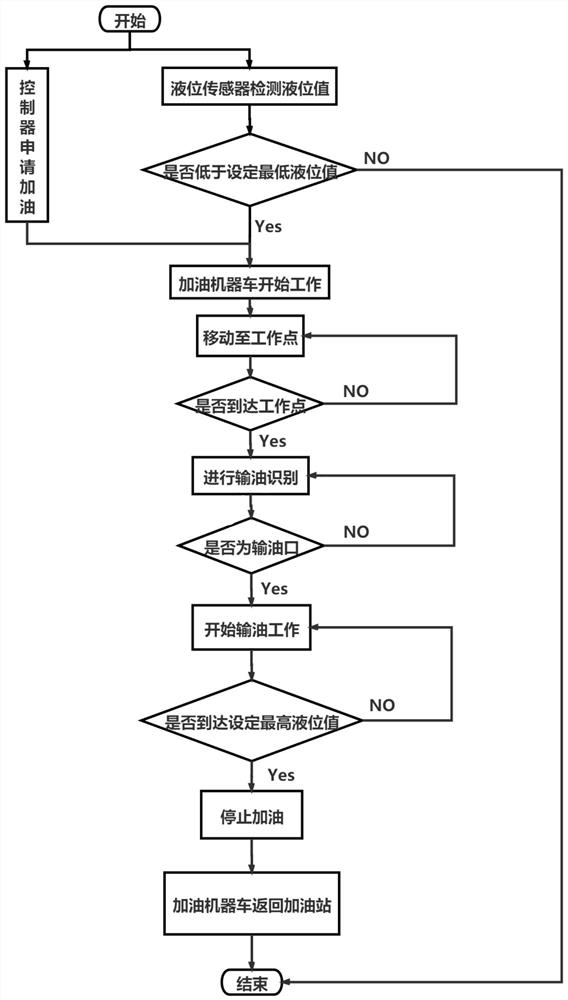

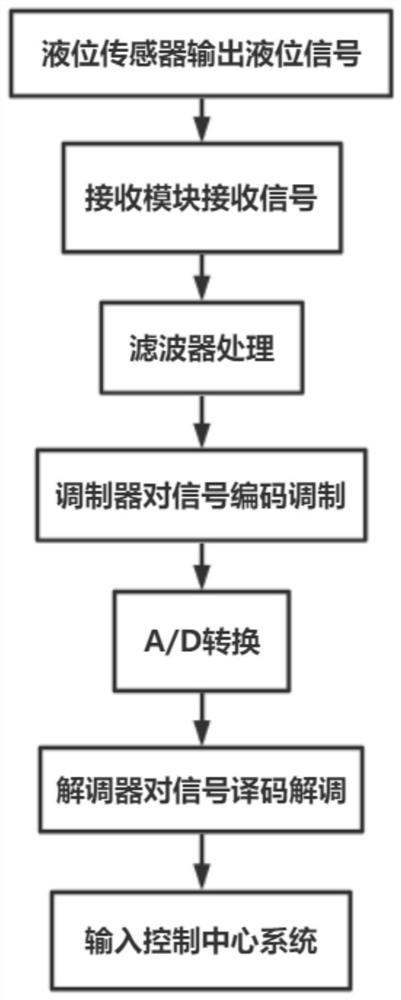

[0018] Such as Figure 1 to Figure 4 As shown, the present invention provides an unmanned refueling system for underground explosion-proof vehicles, which is mainly applied to the refueling work of explosion-proof vehicles under complex geological conditions. The refueling work is regulated according to the underground environment, and the oil can be accurately transported to the corresponding position, and the transportation progress It can monitor in real time and meet the requirements of intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com