Volute structure

A volute and lower volute technology, applied in pump control, components of pumping devices for elastic fluid, non-variable-capacity pumps, etc., can solve the problem of low machining accuracy, reduce pump head and efficiency, increase pump Hydraulic loss and other problems, to achieve the effect of simple and efficient processing and manufacturing, solving reliability problems, and reducing overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

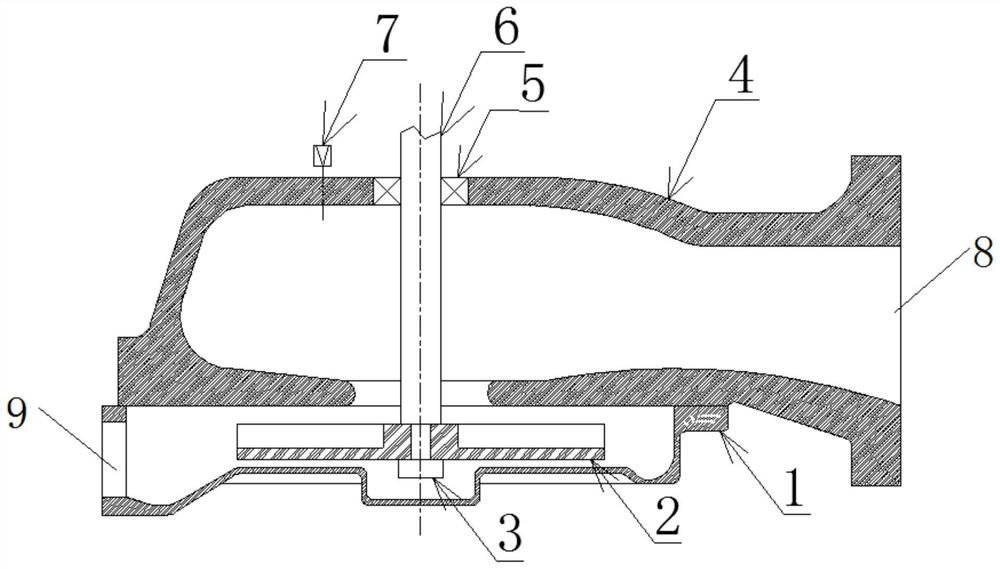

[0019] figure 1 It is a structural schematic diagram of the present invention, as shown in the above figure: the volute structure provided by the present invention includes: lower volute 1, impeller 2, impeller nut 3, upper volute 4, mechanical seal structure 5, rotating shaft 6, exhaust Valve 7; the upper volute 4 is located below the lower volute 1, the lower volute 1 and the upper volute 4 are fixed together by a fixing device; the impeller 2 is installed on the rotating shaft 6; the liquid inlet 8 is located on the upper volute 4; The liquid outlet 9 is located on the lower volute 1 ; the impeller 2 is located in the lower volute 1 ; the rotating shaft 6 passes through the upper volute 4 and the lower volute 1 .

[0020] The accommodating chamber of the upper volute 4 is larger than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com