Production and use method of special strains for agaric fungus bags

A technology of bacterial species and bacterial bag, applied in the fields of botanical equipment and methods, application, horticulture, etc., can solve the problems of affecting the production of edible fungi, easy to be injured by over-temperature, insufficient oxygen supply, etc. Conducive to industrialization, convenient packaging and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

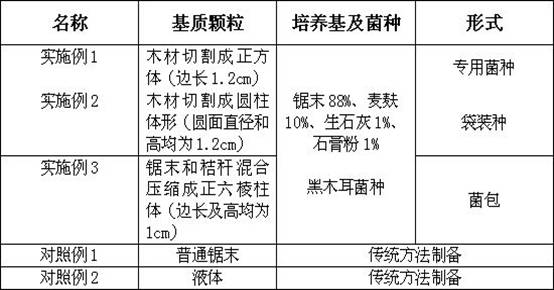

[0033] Embodiment 1-3: the preparation of special bacterial classification, bagged kind and bacterial bag:

[0034] Prepare the strains, bagged seeds, and bacterial packs of Examples 1-3, and the solid strains and liquid strains of Comparative Examples 1-2 in the manner shown in the table below and the method provided in the present invention.

[0035]

experiment example 1

[0036] Experimental Example 1: Cultivate black fungus:

[0037] Prepare the bacterial bag according to the traditional method, punch a hole in the middle, and the aperture is slightly smaller than the outer diameter of the special strain matrix particle,

[0038] 1) Position and inoculate the special strain in Example 1 in the middle hole, the distance from the strain to the bottom of the middle hole is about 3 / 4 of the depth of the middle hole, as Experimental Example 1;

[0039] 2) Take out the special bacteria in the bagged bacteria in Example 2 and inoculate them in the middle hole. The distance from the bacteria to the bottom of the middle hole is about 3 / 4 of the depth of the middle hole, as Experimental Example 2;

[0040] 3) The bacterial bag in Example 3 is used as Experimental Example 3;

[0041] 4) Add the sawdust bacteria and liquid bacteria into the middle well, as the control example 1-2.

[0042] name Training success rate Miscellaneous bacteria r...

experiment example 2

[0044] Experimental example 2: Mycelium temperature in the bacteria bag:

[0045] experiment number ambient temperature Mycelium temperature in the bag Experimental example 1 10℃ 15℃ Experimental example 2 10℃ 16℃ Experimental example 3 10℃ 15℃ Comparative example 1 10℃ 38℃ Comparative example 2 10℃ 41℃

[0046] As can be seen from the above experimental results, the sawdust bacteria and liquid bacteria in Comparative Examples 1 and 2 blocked the respiratory passage of the mesopore, resulting in serious overheating in the bacterial bag. If left for another week, the mycelium would die from overheating. However, in Experimental Example 1-3, the bacteria packs inoculated with special strain blocks are used, the middle holes can be ventilated, the temperature of the bacteria is limited, and there is no harm to the mycelium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com