Activation treatment process for preparing synthetic activated carbon

A technology of activated carbon preparation and activation treatment, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of short contact time, small contact area, failure of activated carbon production, etc., to increase the contact area and duration, slow down The effect of improving the falling speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

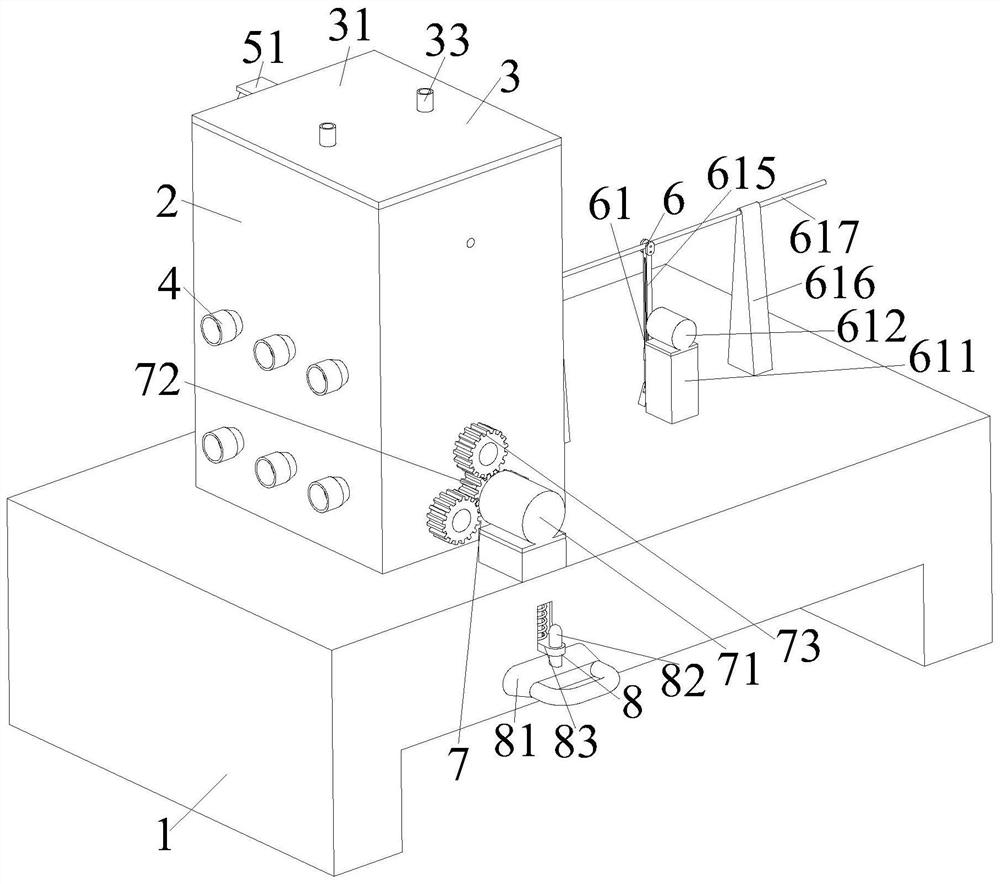

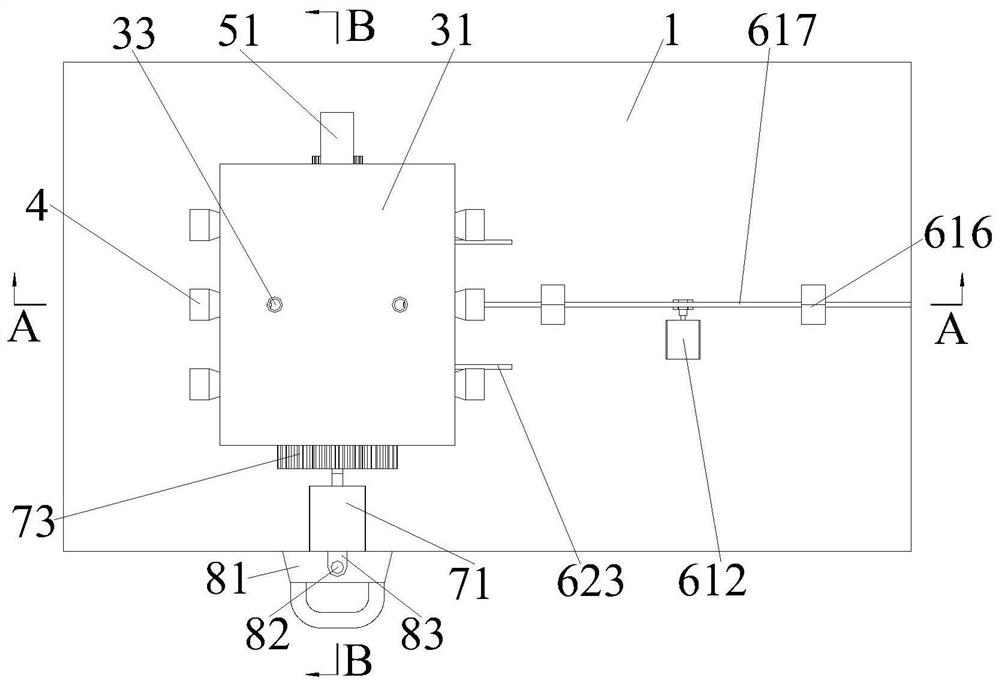

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

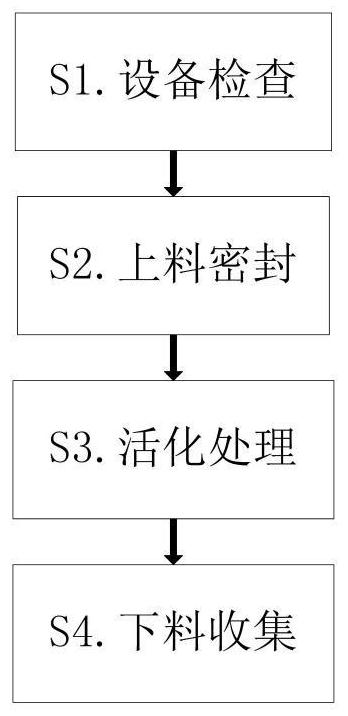

[0041] A synthetic activated carbon preparation activation treatment process, the specific activation treatment process is as follows:

[0042] S1. Equipment inspection: check the synthetic activated carbon production equipment before using it to make synthetic activated carbon;

[0043] S2. Feeding and sealing: After the equipment inspection is completed, manually place the granules or powdery carbonized particles in the sealing device 3, and seal the preparation frame 2 through the sealing device 3;

[0044] S3. Activation treatment: After the feeding is completed, water vapor is input into the preparation frame 2 through the air inlet head 4 to activate the carbonized particles. During the activation process, the carbonized particles and water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com