One-bath quick-bleaching agent for printing and dyeing and preparation method and application of one-bath quick-bleaching agent

A technology of pharmaceuticals and dyes, applied in the field of printing and dyeing auxiliaries, can solve the problems of polluting the environment, increasing the burden of sewage treatment, high energy consumption, time and labor costs, and achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

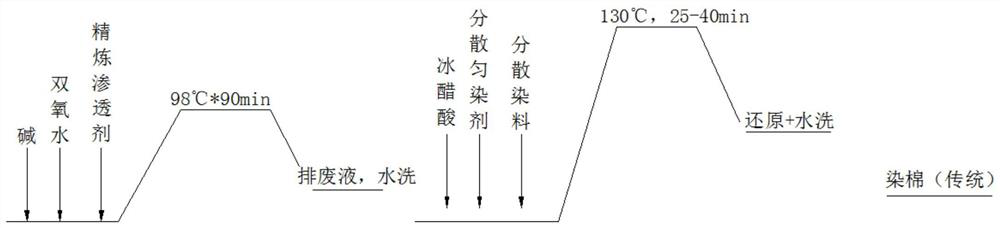

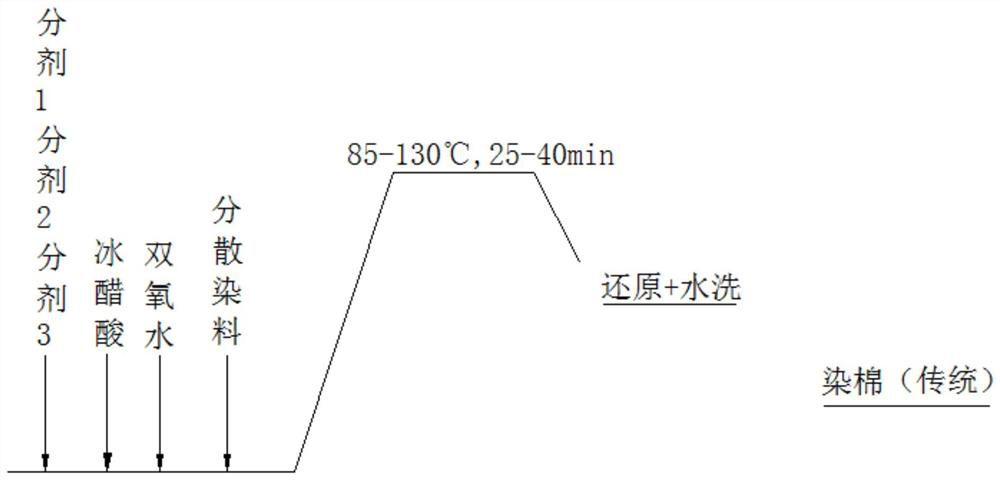

Method used

Image

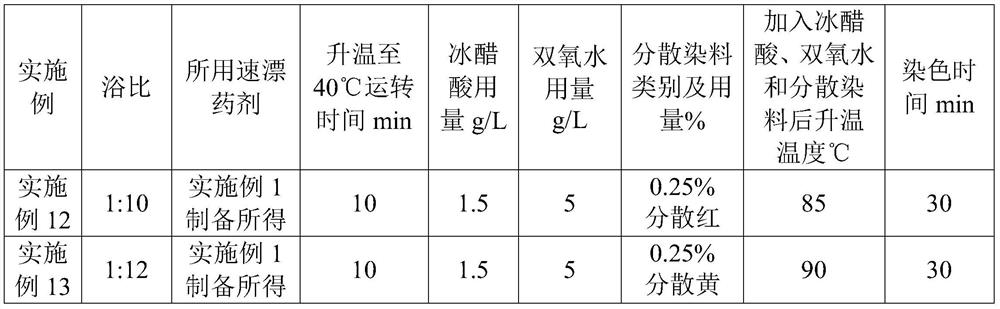

Examples

Embodiment 1

[0028] A one-bath quick bleaching agent for printing and dyeing, the quick bleaching agent includes sub-agent I, sub-agent II and sub-agent III, the mass ratio of sub-agent I:sub-agent II:sub-agent III is 1:1:2; Dispensing agent I comprises the fiber amorphous region channel expander accounting for 88% of its total mass, and the balance is water; the fiber amorphous region channel expander comprises the following components accounting for its total mass: 38% benzyl benzoate, 14% diethylene glycol phthalate, 23% dibutyl maleate, 15% isomeric tridecyl alcohol polyoxyethylene ether, 10% ethylene glycol butyl ether; The dispersant povidone K30 of quality 10%, surplus is water; Described sub-agent III comprises the HO(C that accounts for its gross mass 27%) 4 h 2 o 5 m 2 )nNa, and the balance is water.

[0029] A preparation method for printing and dyeing with one-bath fast bleaching agent, comprising the following steps:

[0030] (a) Heat and stir benzyl benzoate, diethylene ...

Embodiment 2

[0034] A one-bath quick bleaching agent for printing and dyeing, the quick bleaching agent includes sub-agent I, sub-agent II and sub-agent III, the mass ratio of sub-agent I:sub-agent II:sub-agent III is 1:1:2; Dispensing agent I comprises the fiber amorphous zone channel expander accounting for 88% of its total mass, and the balance is water; the fiber amorphous zone channel expander comprises the following components accounting for its total mass: 30% benzyl benzoate, 15% diethylene glycol phthalate, 25% dibutyl maleate, 20% isomeric tridecyl alcohol polyoxyethylene ether, 10% ethylene glycol butyl ether; The dispersant povidone K30 of quality 9%, surplus is water; Described sub-agent III comprises the HO (C 4 h 2 o 5 m 2 )nNa, and the balance is water.

[0035]According to the raw material and proportioning of the above-mentioned bath speed bleaching agent and according to the preparation method of printing and dyeing described in embodiment 1, the preparation method o...

Embodiment 3

[0037] A one-bath quick bleaching agent for printing and dyeing, the quick bleaching agent includes sub-agent I, sub-agent II and sub-agent III, the mass ratio of sub-agent I:sub-agent II:sub-agent III is 1:1:2; Dispensing agent I comprises the fiber amorphous region channel expander accounting for 88% of its total mass, and the balance is water; the fiber amorphous region channel expander comprises the following components accounting for its total mass: 40% benzyl benzoate, 10% dipropylene glycol phthalate, 25% dibutyl maleate, 20% isomeric tridecyl alcohol polyoxyethylene ether, 5% ethylene glycol butyl ether; the sub-agent II includes 11.6% of its total mass % of the dispersant povidone K30, and the balance is water; the sub-agent III includes 25-30% of the total mass of HO (C 4 h 2 o 5 m 2 )nNa, and the balance is water.

[0038] According to the raw material and proportioning of the above-mentioned bath speed bleaching agent and according to the preparation method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com