Design method of impeller inlet of supercritical carbon dioxide centrifugal compressor

A centrifugal compressor, impeller import technology, applied in computer-aided design, mechanical equipment, design optimization/simulation, etc., can solve problems such as reducing the compactness of the compressor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

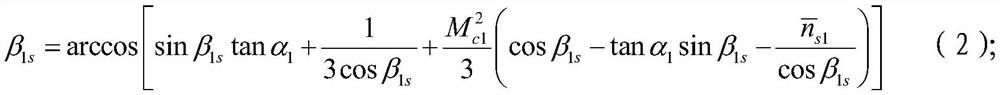

[0100] Embodiment: Take the impeller inlet design of a supercritical carbon dioxide compressor of a certain Brayton thermodynamic cycle as an example for illustration:

[0101] (1) Given the total temperature T of the impeller inlet of the supercritical carbon dioxide compressor t1 =310K, the total pressure of impeller inlet p t1 =8MPa, target flow function Φ=0.0118, machine Mach number M u2 =0.8799, pre-swirl intake angle α 1 =0deg; according to the total inlet temperature T t1 and total inlet pressure p t1 , using the thermal and transport properties database REFPROP to get the total import enthalpy h t1 =381.94kJ / kg;

[0102] (2) Determine the total entropy S of the impeller inlet t1 , impeller inlet static entropy S 1 , Acceptable acceleration margin empirical coefficient λ and steam fraction Q value:

[0103] Ⅰ) According to the total temperature T of the impeller inlet t1 and impeller inlet total pressure p t1 The total entropy S of the impeller inlet is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com