Debutanizer soft measurement modeling method based on ALIESN online learning algorithm

A technology of debutanizer and modeling method, which is applied in the field of soft sensing, can solve the problems that cannot be reached quickly and in real time, high learning cost, complex algorithm, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

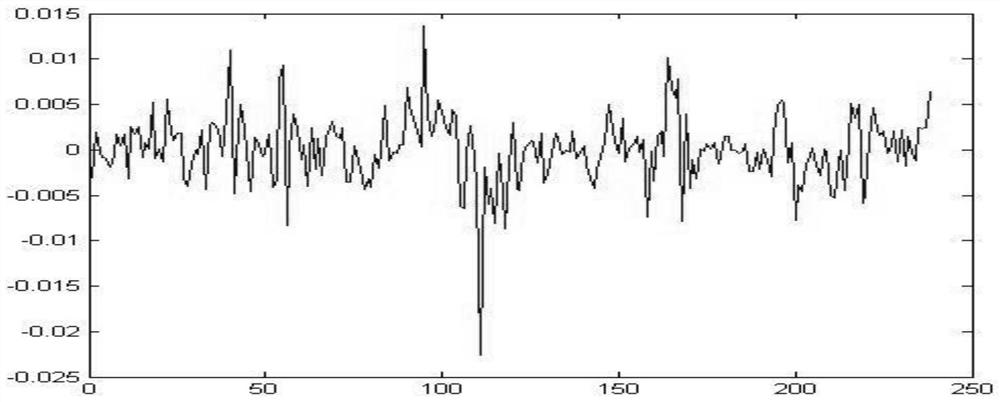

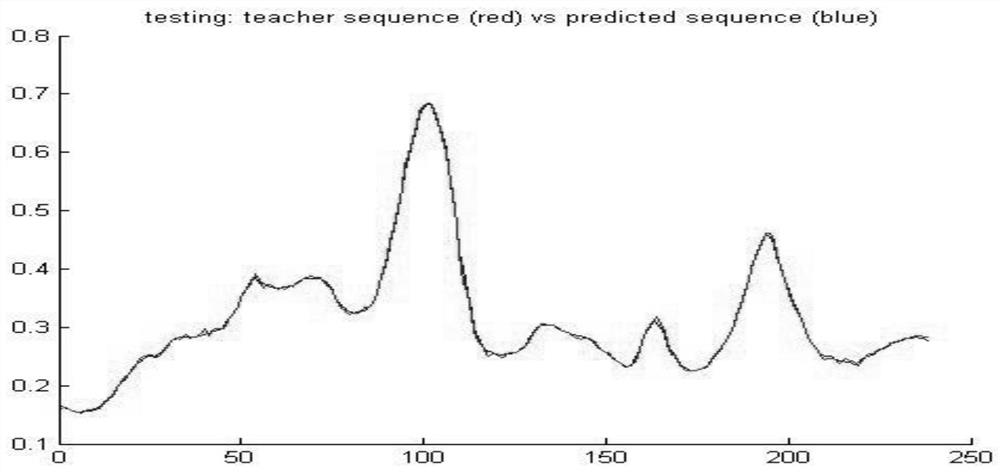

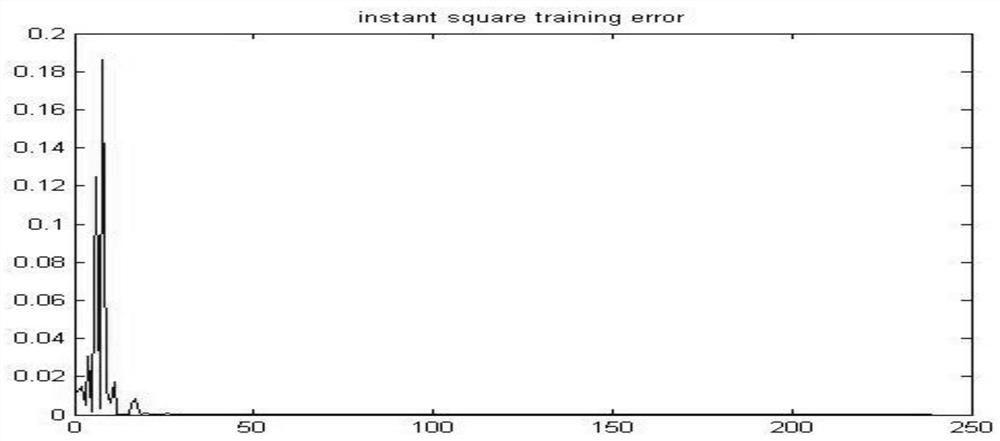

[0066] like Figure 1.1 , Figure 1.2 , Figure 1.3 Shown, the present invention proposes a kind of debutanizer tower soft sensor modeling method based on ALIESN online learning algorithm, and the steps are as follows:

[0067] First, use the measuring instruments installed in the butane tower equipment to measure the values of key variables in real time and perform normalized preprocessing, and record them as 7 auxiliary variables xi and 1 leading variable y, where xi is determined by the value of the ith process variable The sample data composition, i ∈ {1, 2, ..., 7} corresponds to the tower top temperature, tower top pressure, reflux flow rate, bottom product outlet flow rate, tray temperature on the 6th layer, tower bottom temperature A and tower bottom temperature B , and then use the NARX model to model 7 auxiliary variables and 1 leading variable as the input variables of ALIESN;

[0068] Secondly, for the first n data of ALIESN input variables, use the ALIESN ridg...

Embodiment 2

[0072] like Figure 2.1 , Figure 2.2 , Figure 2.3 As shown, using the same conditions as in Example 1 for learning, the mean square error value is 1.466215709364227*10 -5 .

Embodiment 3

[0074] like Figure 3.1 , Figure 3.2 , Figure 3.3 As shown, using the same conditions as in Examples 1 and 2 for learning, the mean square error value is 2.757009214241490*10 -5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com