Combined synchronous generator base and machining method thereof

A synchronous generator and combined technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of difficulty in guaranteeing machining accuracy, difficulty in machine base machining, and long machining cycle, and achieve short machining cycle and improved R&D capabilities and the effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

[0045] In this embodiment, the driving end of the generator seat is the front, and the non-driving end is the rear.

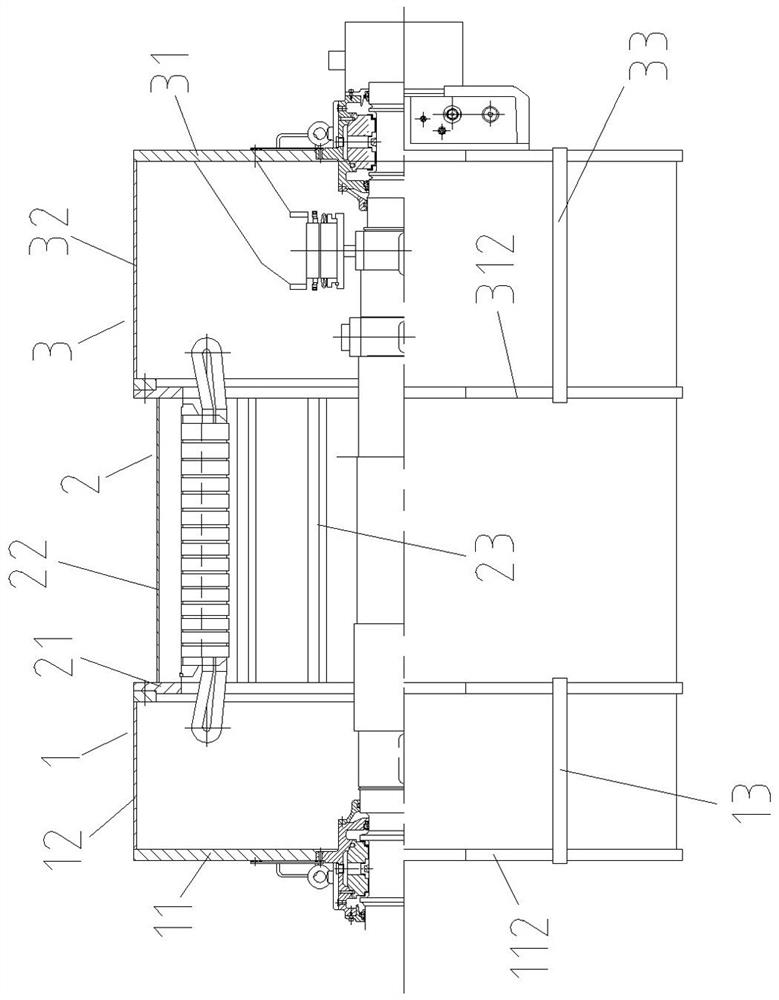

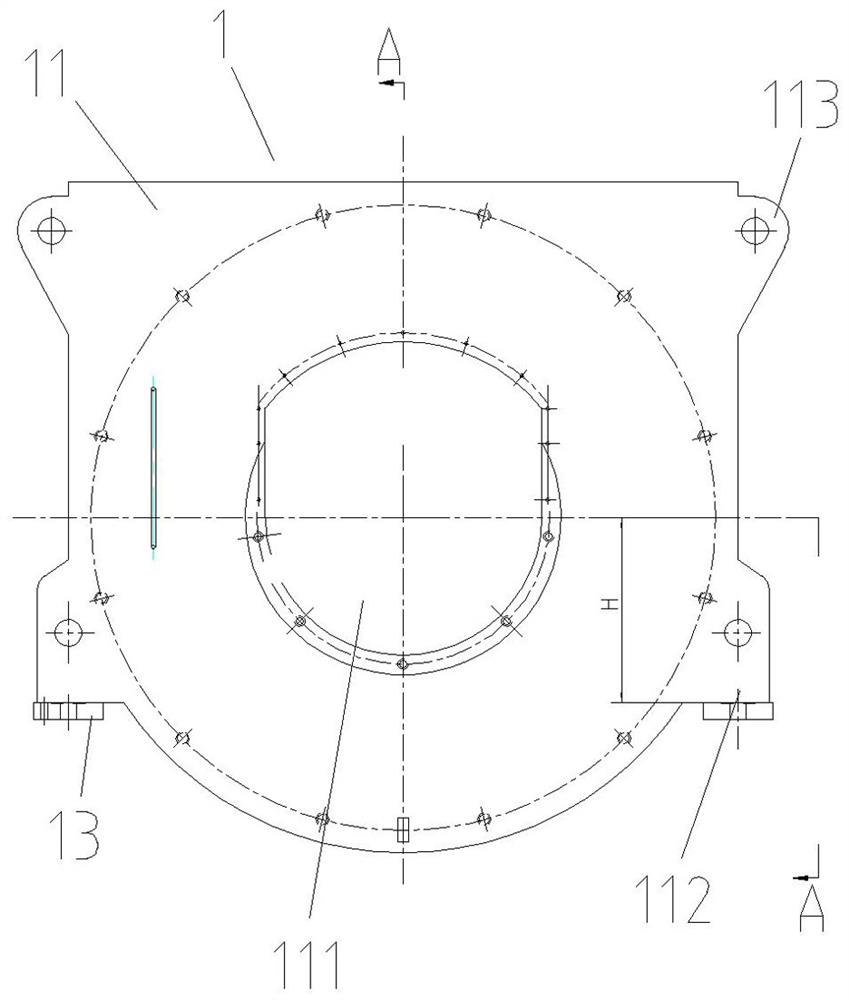

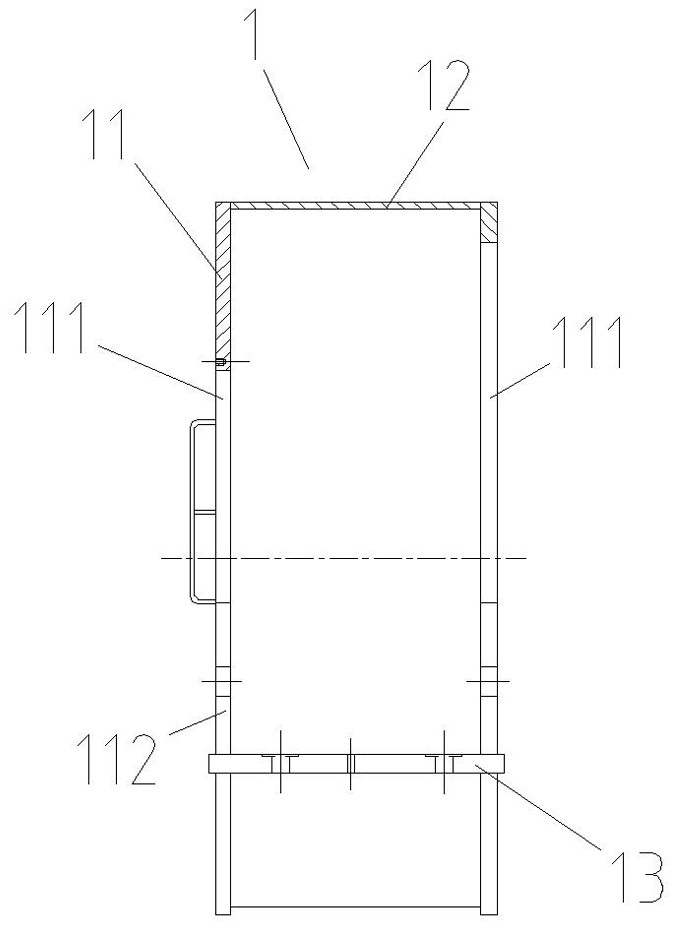

[0046] Such as figure 1 As shown, the present invention includes a front machine base 1, a middle machine base 2 and a rear machine base 3, and the three are sequentially fixed into a whole by fasteners, wherein the front machine base 1 and the rear machine base 3 are square, and the middle machine base Seat 2 is cylindrical. Such as figure 2 and image 3 As shown, the front base 1 includes two front end plates 11, a front housing 12 and two front foot plates 13, and the two front end plates 11 are respectively welded and fixed on the two ends of the front housing 12, and the front end plates 11 of the two The middle part is provided with front mounting hole 111 respectively, and the front mounting hole 111 of outer front end plate 11 is used for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com