Dual-fuel double-oil-supply engine and control method thereof

A control method and engine technology, applied in engine control, combustion engine, fuel injection control, etc., can solve problems such as poor fuel economy, achieve the effect of reducing dependence on gasoline, shortening fuel injection time, and ensuring an effective way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

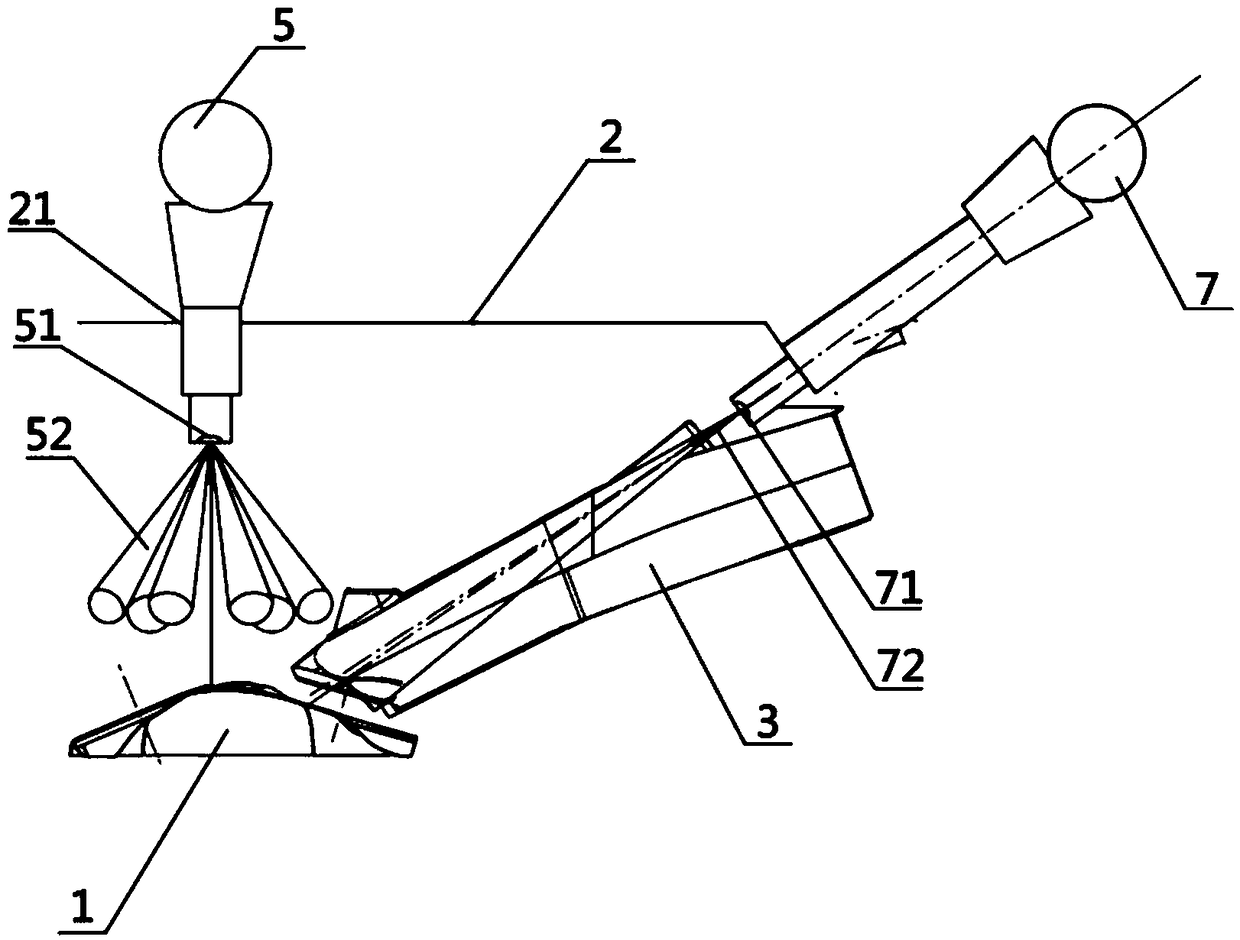

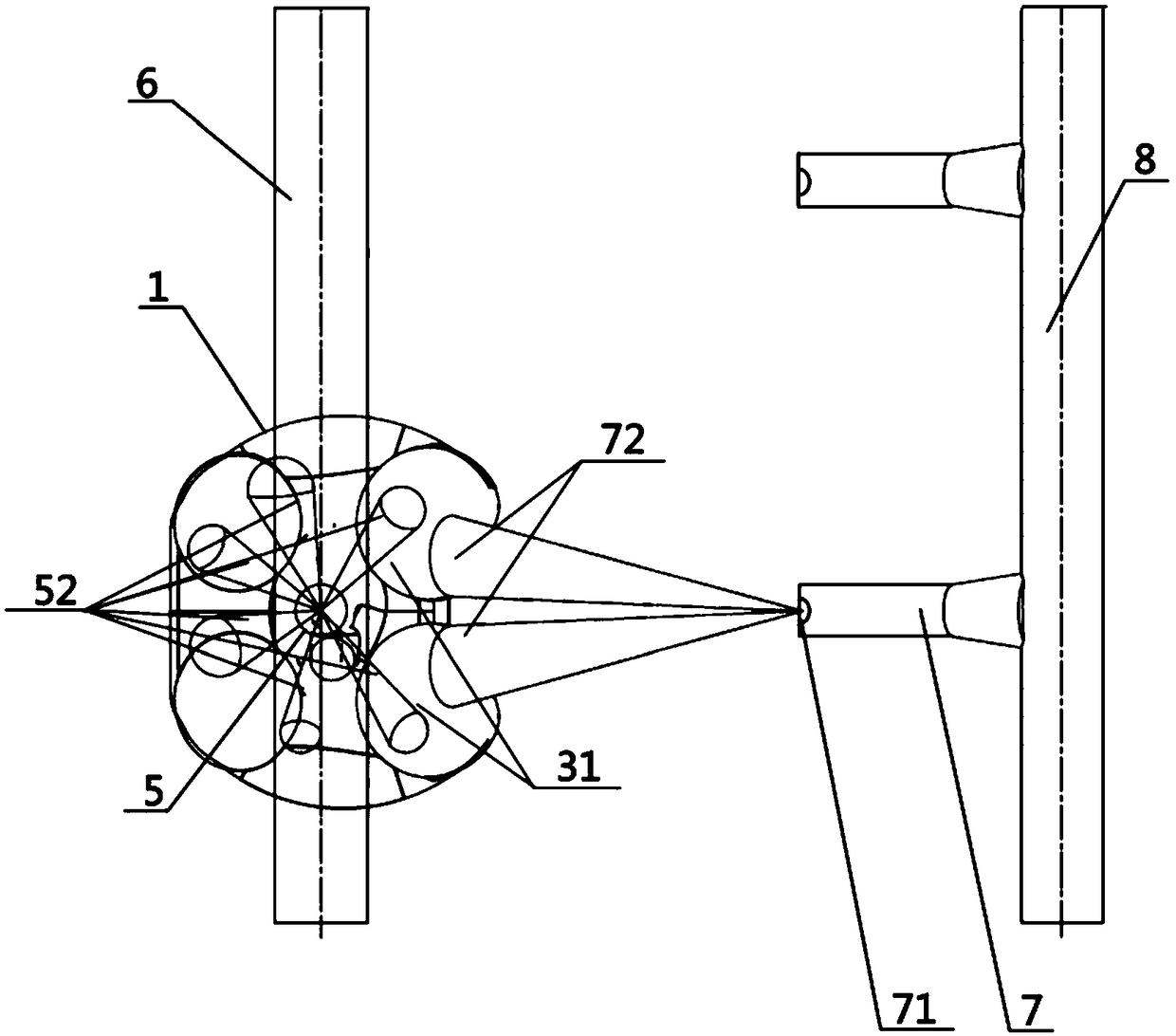

[0049] See figure 1 , figure 2 , a dual fuel dual oil supply engine, comprising a cylinder block 1, a cylinder head 2 is arranged on the top of the cylinder block 1, an intake port 3 communicating with the cylinder block 1 is arranged on the cylinder block 1, and a methanol fuel injection module and The gasoline fuel injection module, the methanol fuel injection module includes a methanol nozzle 5, which is arranged above the cylinder head 2, and is used to inject methanol into the cylinder; the gasoline fuel injection module includes a gasoline nozzle 7, which is arranged on the intake port 3, used to inject gasoline into the intake port 3.

[0050] Therefore, the present invention adopts two different oil supply methods, the methanol nozzle is arranged above the cylinder head, and the methanol is directly injected into the cylinder by the high-pressure direct injection method, which has a higher compression ratio, so that the amount of methanol injection can be larger and ...

Embodiment 2

[0064] There are two or more cylinder blocks 1, and each cylinder block 1 is located on the same straight line. All the other parts are the same as the first embodiment.

[0065] The present invention can also be applicable to multi-cylinder engine, wherein, methanol nozzle is arranged on the methanol injection rail, and the quantity of methanol nozzle is corresponding to the quantity of cylinder head; Gasoline nozzle is arranged on the gasoline injection rail, and the quantity of gasoline nozzle and Corresponding to the number of intake channels. As a result, the actual fuel inside each cylinder is approximately equal, and the balance is good, so the present invention has a stable structure and high control precision.

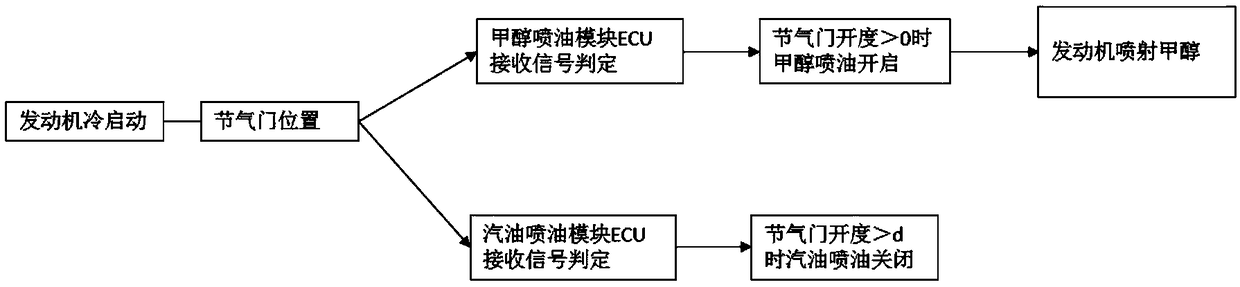

[0066] Embodiment 1 of the control method of dual-fuel dual-fuel-supply engine:

[0067] See image 3 , Figure 4 , a method for controlling a dual-fuel dual-fuel-supply engine, using the above-mentioned dual-fuel dual-fuel-supply engine, and comprising th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com