Single-switch half-bridge electric energy converter

An electric energy converter and single-switch technology, which is applied in the direction of converting the irreversible DC power input into the AC power output with reversible conversion equipment, and can solve the problems of difficult current mode conversion and soft switching control, mutual isolation, and difficulty in Realize problems such as active power factor conversion control and bidirectional power conversion, and achieve the effects of easy current mode conversion and control, low assembly cost, and low cost of mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

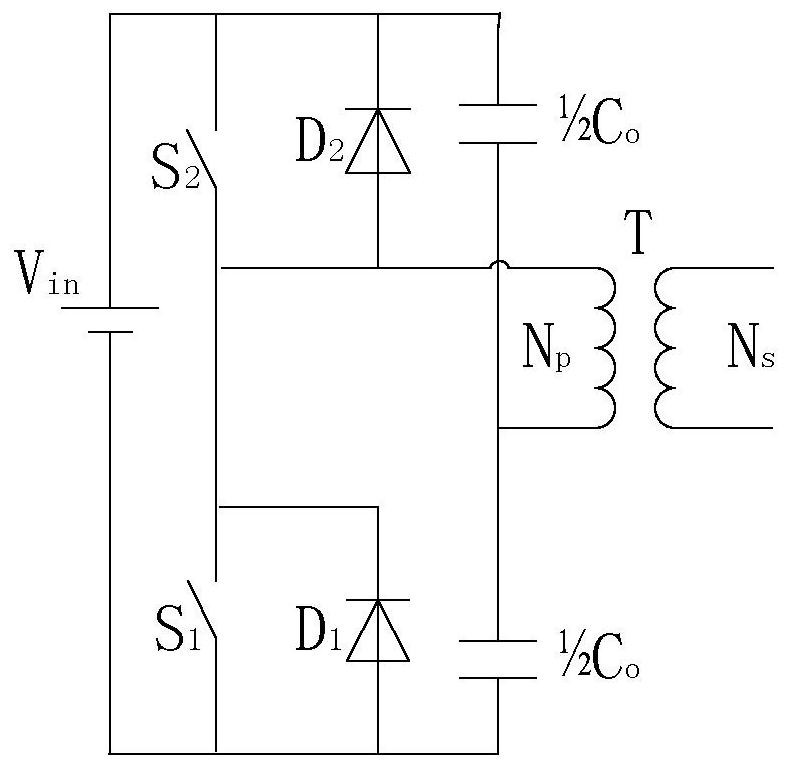

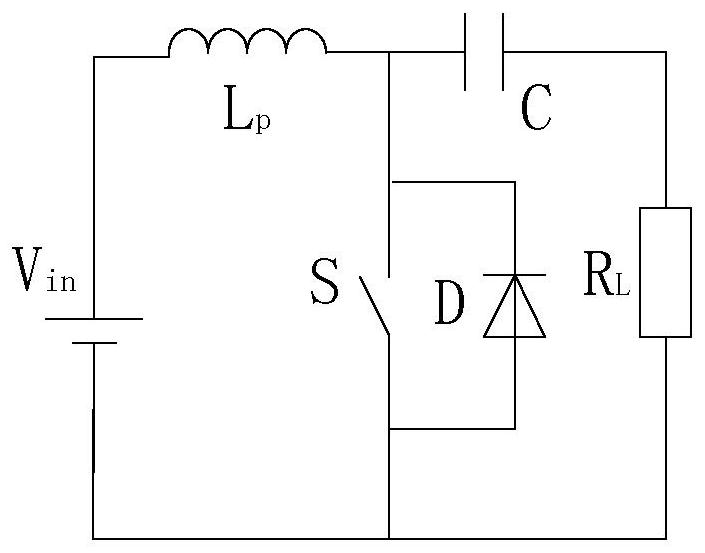

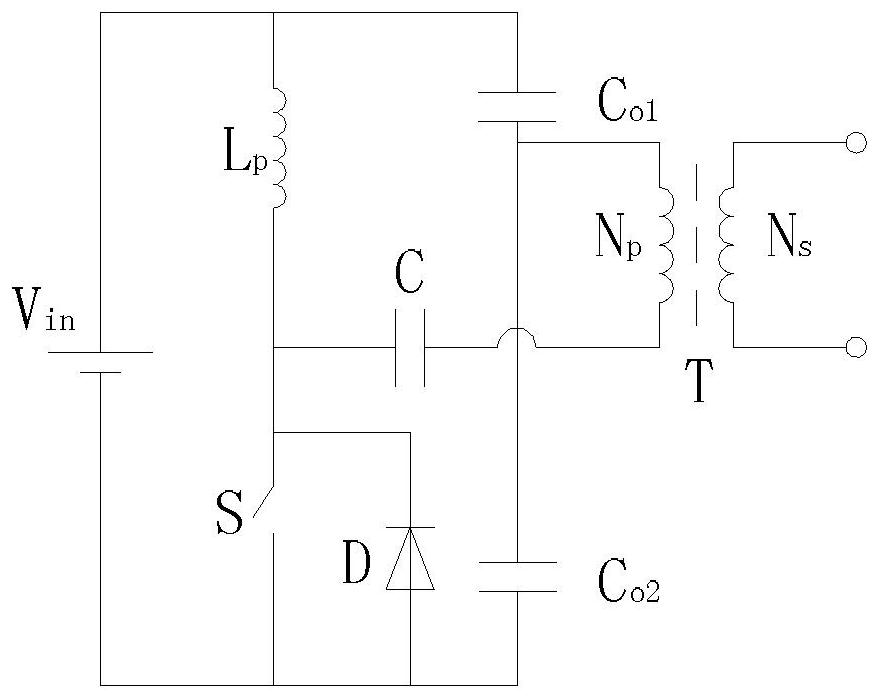

[0041] Specific implementation mode one: refer to image 3 Describe this embodiment in detail, compare figure 1 and figure 2 Two circuit configurations are shown, the figure 1 The capacitive bridge arm in the circuit shown is placed in the figure 2 in the circuit shown, or with figure 2 The inductor L in p replace figure 1 The upper arm switch S in 2 , the connection relationship of other components remains unchanged, and the new circuit structure formed in this way is as follows image 3 As shown, the equivalent circuit of its working principle is as Figure 4 shown. The specific structure is as follows:

[0042] Includes: Inductor L p , capacitance C, capacitance C o1 , capacitance C o2 , switch S, diode D and output transformer,

[0043] One end of the switch S is respectively connected to the negative pole of the DC power supply, the positive pole of the diode D and the capacitor C o2 One end of the switch S and the other end of the switch S are respective...

specific Embodiment approach 2

[0048] Specific implementation mode two: refer to Figure 11 and Figure 12 This embodiment is described in detail. In this embodiment, the lower end of the switch S in the basic conversion unit A is reconnected to one end of the AC input and the input rectifier diode bridge arm at this end is removed; the other end of the AC input is connected to an LC inductor and capacitor input filter. Network; connect the LC capacitor inductance series loop at the original position of the switch S. The specific structure is as Figure 11 As shown, the equivalent circuit of its working principle is as Figure 12 shown.

[0049] Specifically, the single-switch half-bridge power converter described in this embodiment includes: an inductor L i , inductance L p , inductance L R , capacitance C, capacitance C i , capacitance C o , Diode D 1 , Diode D 2 , Diode D 3 , switch S and resistor R LDC ,

[0050] One end of the switch S is respectively connected to one end of the AC power s...

specific Embodiment approach 3

[0057] Specific implementation mode three: refer to Figure 13 Describe this embodiment in detail. The single-switch half-bridge power converter described in this embodiment is characterized in that it includes: an inductor L i , inductance L p , capacitance C b , capacitance C i , capacitance C o1 , capacitance C o2 , Diode D 1 , Diode D 2 , Diode D 3 , switch S, resistor R LAC and resistor R LDC ,

[0058] One end of the switch S is respectively connected to one end of the AC power supply and the capacitor C i One end of the switch S and the other end of the switch S are respectively connected to the inductor L p One end and the capacitor C b at one end, the inductance L i One end is connected to the other end of the AC power supply, the inductance L i Connect the other end of the capacitor C i The other end of the diode D 2 anode and diode D 1 the cathode of the diode D 3 In parallel across the switch S, the diode D 2 The negative poles of the inductors a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com