Mixing device for tea oil processing

A mixing device and camellia oil technology, applied in mixers, mixers with rotating containers, mixers with rotating stirring devices, etc., can solve problems such as low mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

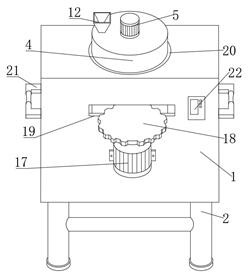

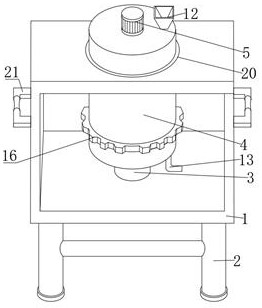

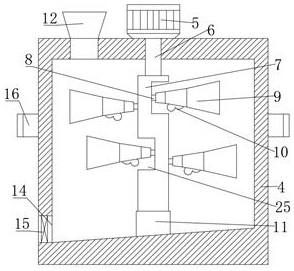

[0026] refer to Figure 1-4 , a mixing device for tea oil processing, comprising a box body 1, a plurality of legs 2 are symmetrically fixed on both sides of the bottom of the box body 1 by bolts, the box body 1 is set to be closed at the front end and open at the rear end, and the bottom of the box body 1 is fixed by bolts There is a pillar 3, and the top of the pillar 3 is connected to the mixing cylinder 4 through hinge rotation, the mixing cylinder 4 and the top of the box body 1 are arranged through, and the same second bearing 20 is fixed between the mixing cylinder 4 and the box body 1 by bolts, and the mixing cylinder 4 The top is fixed with a variable speed motor 5 by bolts, the output shaft of the variable speed motor 5 runs through the mixing cylinder 4 and is connected with a connecting rod 6, the bottom of the connecting rod 6 is welded with a straight shaft 7, and the bottom of the inner wall of the mixing cylinder 4 is fixed with a first bearing 11, a straight sh...

Embodiment 2

[0031] refer to Figure 1-5 , a mixing device for tea oil processing, the track changing mechanism is provided with a plurality of grooves 25 on both sides of the straight shaft 7, the grooves 25 on both sides are arranged at intervals, the inner surface of the groove 25 is provided with a chute 26, and the chute Slider 27 is slidably connected in 26, and slide block 27 outsides and connecting rod 8 are welded and fixed, and chute 26 tops are fixed with spring 28 by bolts, and spring 28 bottoms and slide block 27 tops are fixed by bolts.

[0032]During use, when the stirring paddle 9 is rotated by the different centrifugal forces of the variable speed motor 5, it drives raw materials such as camellia oil to rotate, and the rotating raw materials such as tea oil provide different vertical forces to the stirring paddle 9, so that the stirring paddle 9 and the continuous The rod 8 moves up and down in the chute 26 following the slider 27, thereby further making the stirring paddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com