Recovery device capable of disassembling milk bottles in batches

A recycling device and feeding bottle technology, which can be used in the removal of solid waste, metal processing, metal processing equipment, etc., can solve the problems of resource waste, infant health injury, breeding of bacteria, etc., to save resources, protect the environment, and improve the efficiency of recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

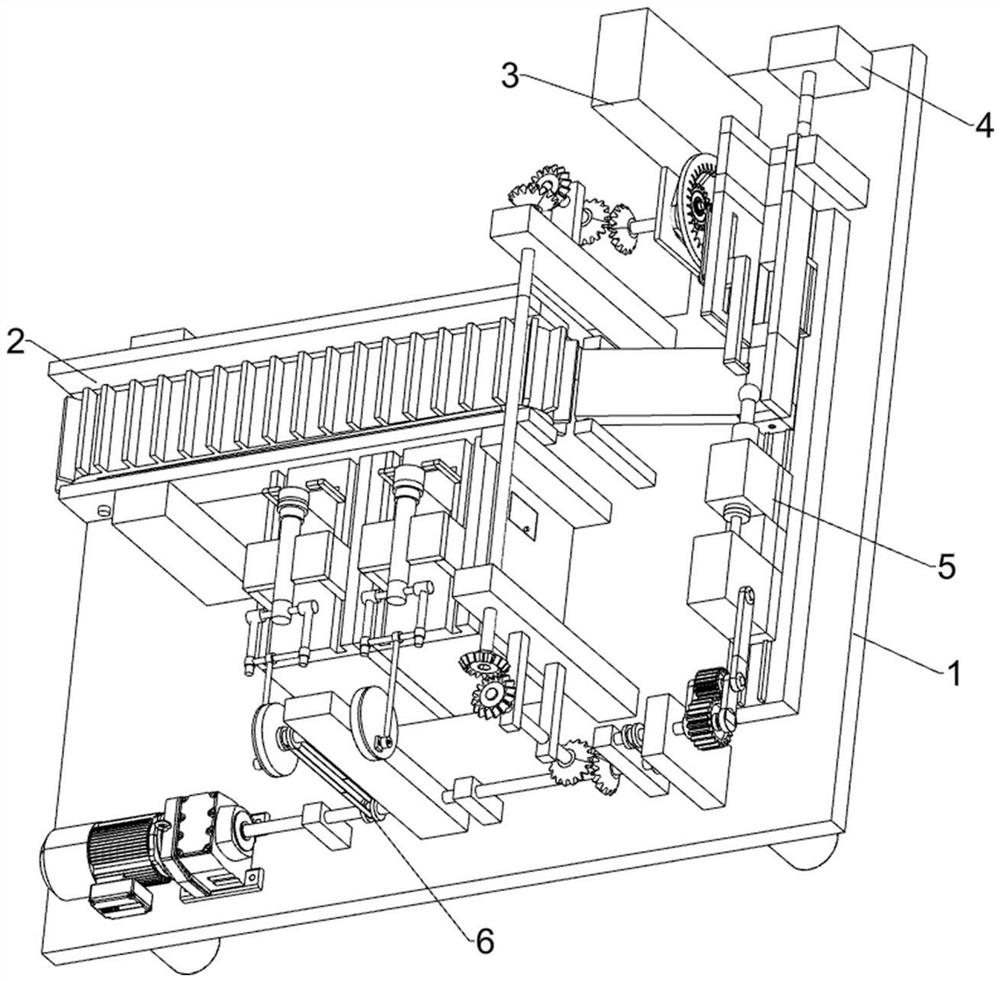

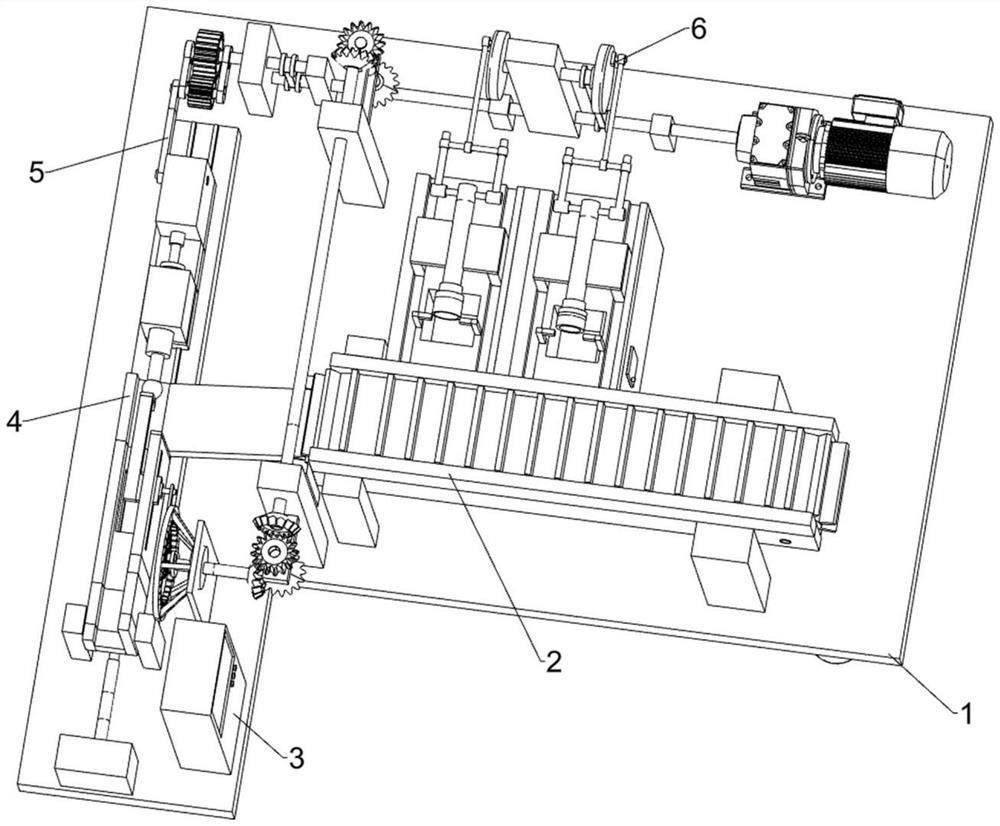

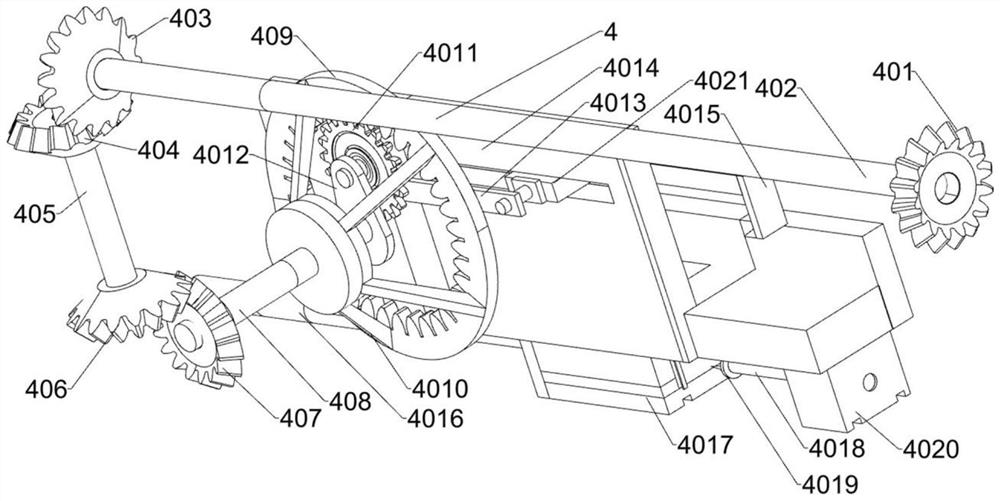

[0025] A recovery device capable of dismantling feeding bottles in batches, such as Figure 1-5 As shown, it includes a workbench, a conveyor belt, a control panel, a pad removal mechanism, an inner bottle take-out mechanism and a twisting mechanism; the workbench is connected to the conveyor belt; the workbench is connected to the control panel; The table is connected with the inner bottle take-out mechanism; the working table is connected with the torsion mechanism; the pad removal mechanism is connected with the inner bottle take-out mechanism; the inner bottle take-out mechanism is connected with the torsion mechanism.

[0026]Working principle: When using this device, firstly open and adjust the device through the control panel, then manually put the feeding bottle on the conveyor belt, and then transfer the feeding bottle to the working place through the conveyor belt on the workbench, take out the feeding bottle cap and nipple through the twisting mechanism, and then Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com