Modular device used for circulation and storage of rotor assemblies of electric machine

A modular, rotor technology, applied in the parts, packaging, internal accessories of bottles/cans, etc., can solve the problems of expanding the use area, motor burnout, use area, etc., to improve stability and consistency, Improve the production qualification rate, improve the effect of life and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

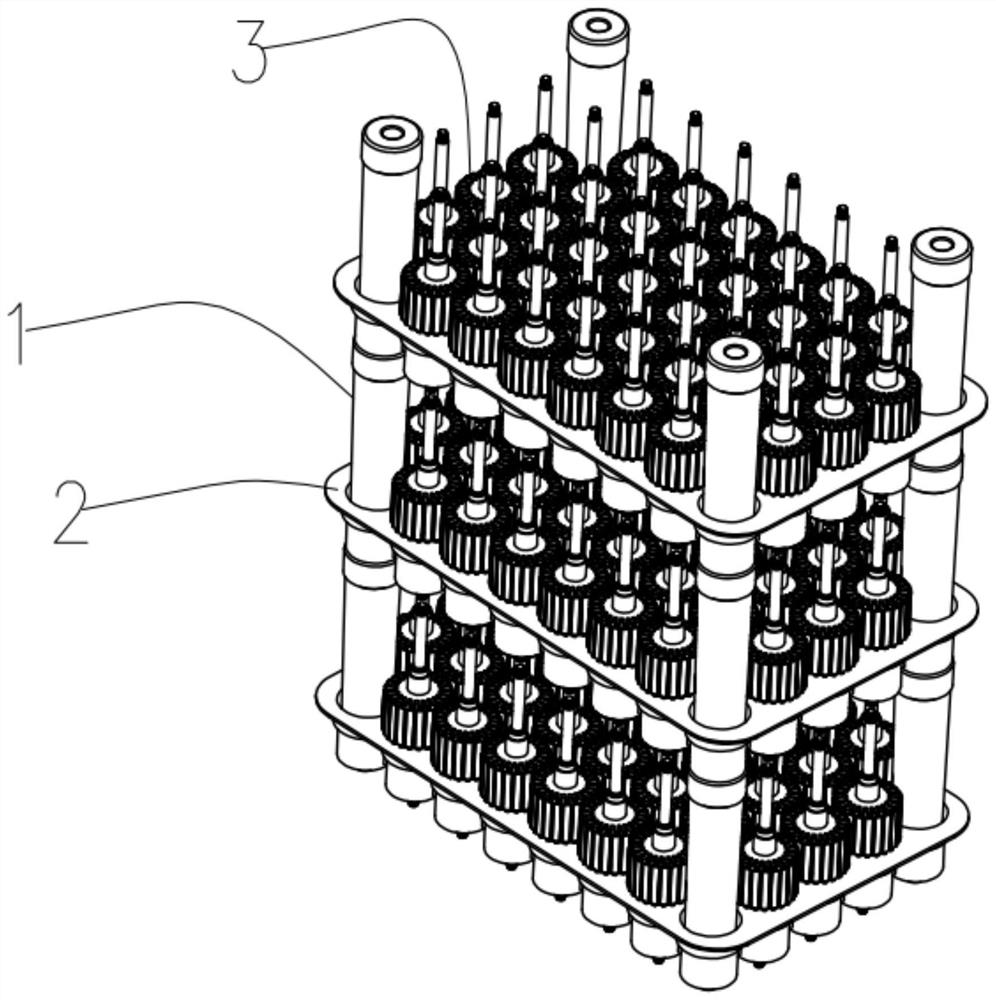

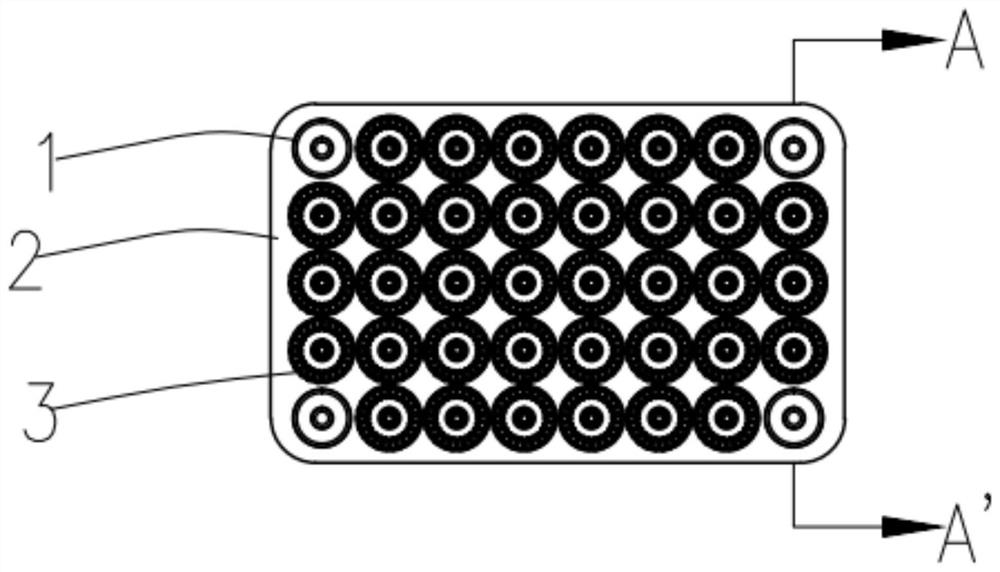

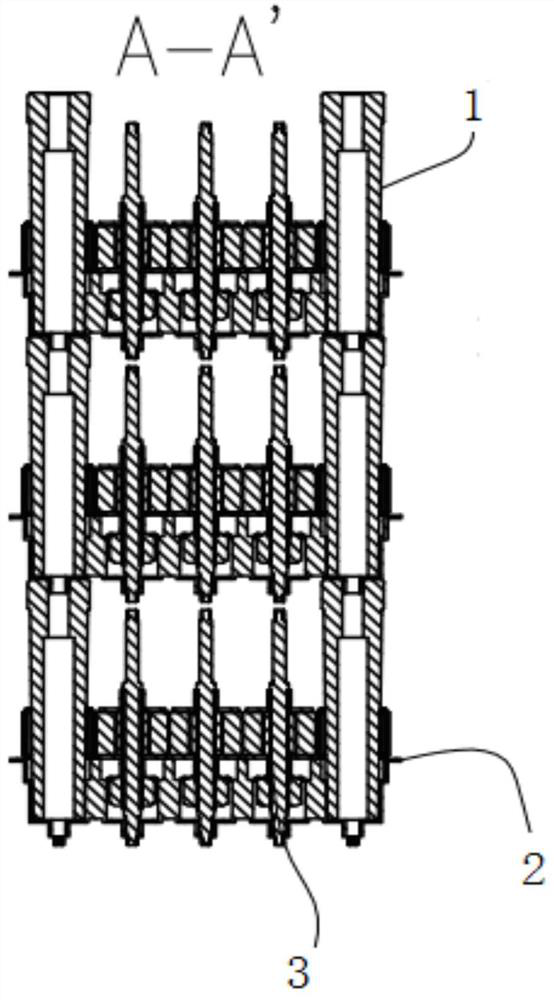

[0028] See Figure 1~5 , the present invention is a modular device for the turnover and storage of the rotor assembly of the motor, which includes a support column 1 and several rotor assembly turnover tools 2, and the rotor assembly turnover tool 2 includes a turnover bottom plate 7 and several rotor assembly chambers 8, and several rotor assemblies The component chambers 8 are evenly distributed on the upper surface of the revolving bottom plate 7 . The lower end of the support column 1 is inserted into the rotor assembly 8 at the four corners of the turnover base plate 7, and the rotor assembly 3 is placed in the rotor assembly chamber 8. When the rotor assembly chamber 8 is filled, the rotor assembly turnover tool 2 on the upper layer passes through the turnover base plate 7 The bottom is fixed on the support column 1, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com