Circuit laminated film for wafer-level packaging and sealing, its preparation method and application

A wafer-level packaging and sealing technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve the problems of unsuitable large-sized wafer-level packaging and difficult-to-embed sealed objects, so as to improve product quality, Effect of low thermal expansion coefficient and high storage modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

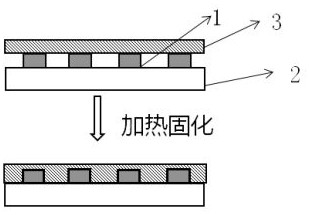

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and beneficial effect of the present invention more clear, the specific implementation manners of the present invention will be further described in detail below. It should be understood that the described specific embodiments are only used to explain the present invention, and are not intended to limit the present invention.

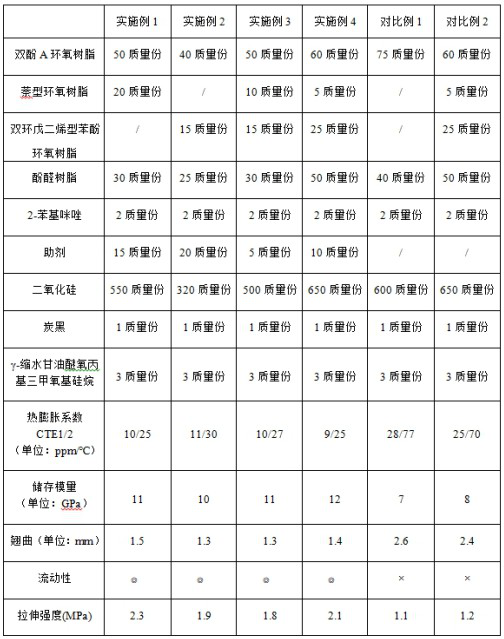

[0037] The circuit laminated film for wafer-level packaging and sealing provided by the present invention includes epoxy resin, 25-50 parts by mass of curing agent, 0.1-5 parts by mass of curing accelerator, 5-20 parts by mass of auxiliary agent, 320 The inorganic filler of ~650 mass parts, the silane coupling agent of 0.01 ~ 5 mass parts; Described epoxy resin comprises the first type epoxy resin of 40 ~ 60 mass parts and the second type epoxy resin of 15 ~ 30 mass parts , the first type of epoxy resin is one or more of bisphenol A epoxy resin, bisphenol F epoxy resin, biphenyl epoxy resin, prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com