Assembly type low pile bearing platform revetment suitable for muddy foundation and construction method

A prefabricated, silty technology, applied in basic structure engineering, bank piers, bank walls, etc., can solve the problems of long construction period, large construction interface, occupation of river channels, etc., and achieve good construction quality, small environmental impact, and good ecology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, not to limit the present invention.

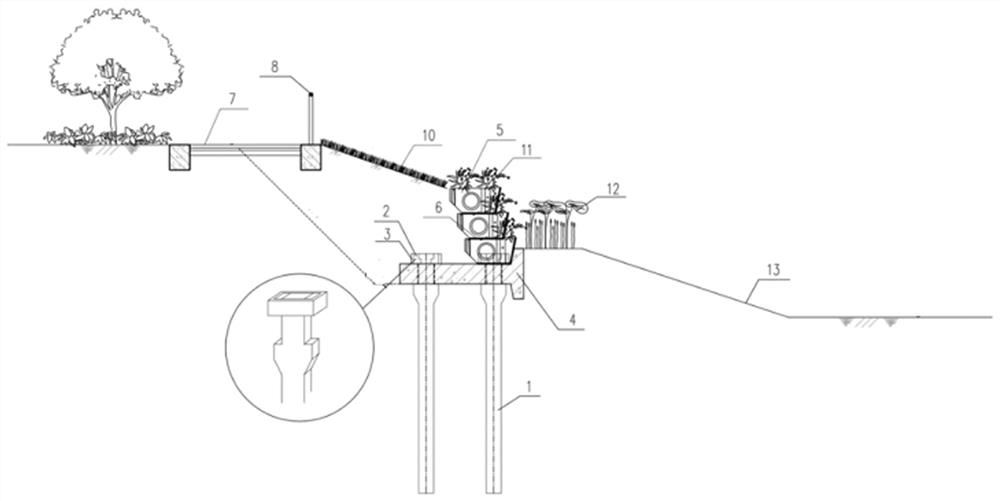

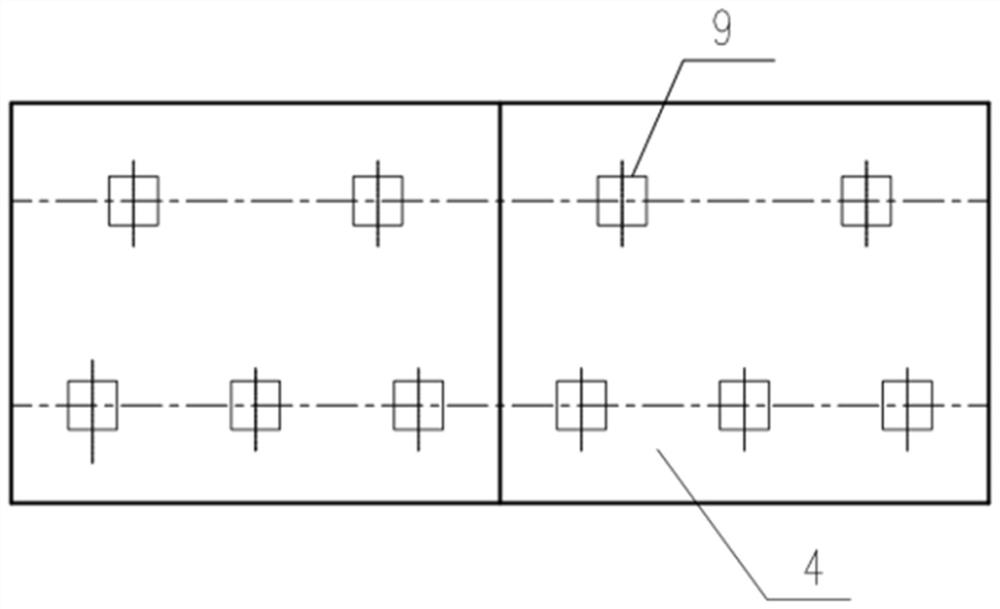

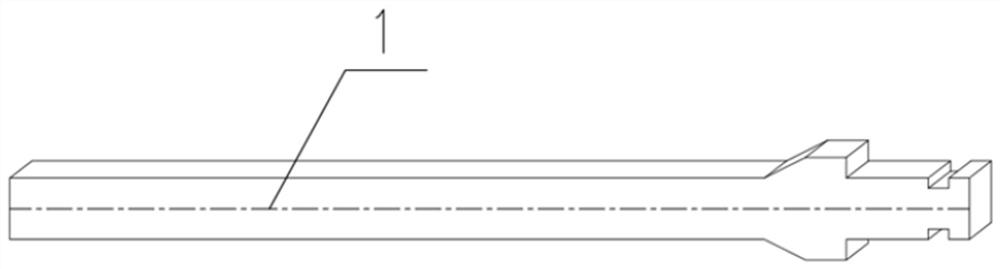

[0038] An assembled low pile cap bank revetment suitable for muddy ground, characterized in that: the assembled low pile cap bank revetment includes prefabricated square piles 1 inserted into the soil, the top of the prefabricated square piles 1 is provided with a pile head, and the pile Grooves are arranged on both sides of the upper part of the head, pile foundation corbels are arranged under the pile head, and several bottom plate openings are arranged on the prefabricated bottom plate. The prefabricated bottom plate 4 is placed horizontally, and the pile head passes through the bottom plate openings. Erected on the pile foundation corbel, the side grooves of the pile head are located above the prefabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com