Composite-state type motor damping table base

A pedestal and pedestal technology, used in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as poor shock absorption effect and equipment impact, reduce the possibility of resonance, ensure stable operation, Good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

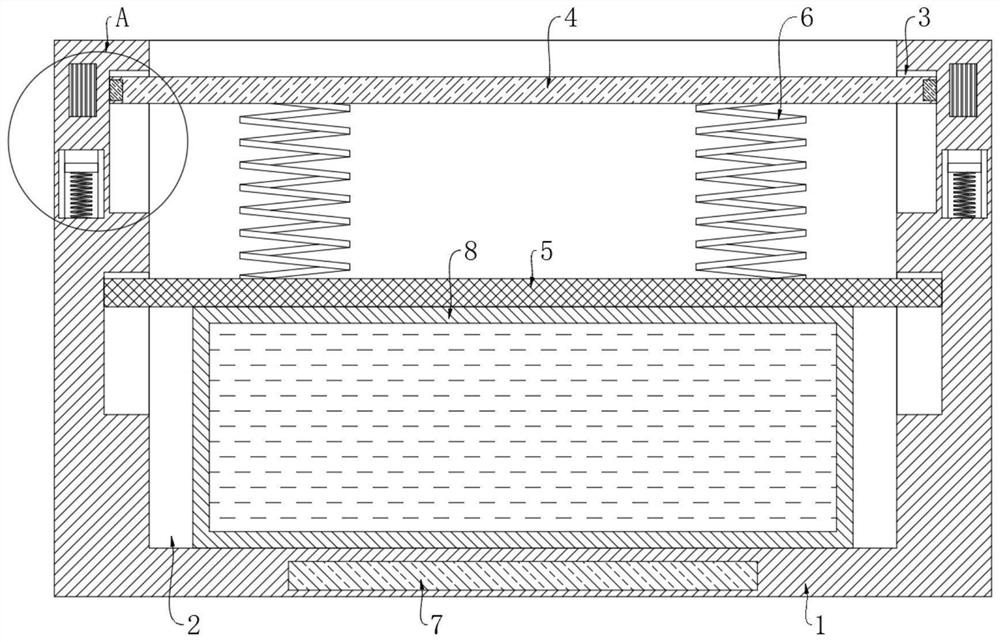

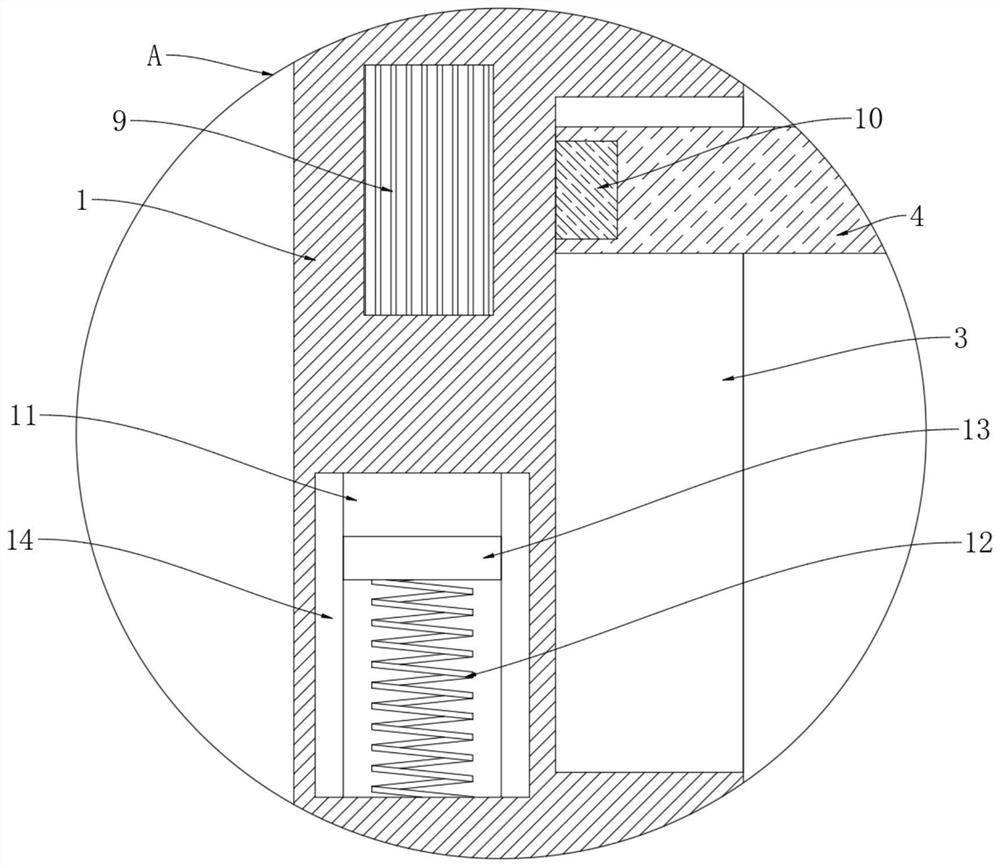

[0017] refer to Figure 1-2 , a composite motor shock-absorbing pedestal, comprising a base 1, the upper end surface of the base 1 is provided with a placement groove 2, and the inner wall of the placement groove 2 is symmetrically provided with a plurality of limiting grooves 3, and the corresponding plurality of limiting grooves The load-bearing plate 4 and the movable plate 5 are slidably connected in 3, and the load-bearing plate 4 is located above the movable plate 5. The load-bearing plate 4 is used to place the working equipment. Spring 6, and the upper and lower ends of a plurality of damping springs 6 are respectively fixedly connected to the lower end surface of the bearing plate 4 and the upper end surface of the movable plate 5, and an elastic airbag is elastically connected between the lower end surface of the movable plate 5 and the bottom groove wall of the placement groove 2 8, and the elastic airbag 8 is filled with magnetorheological fluid (magnetorheological...

Embodiment 2

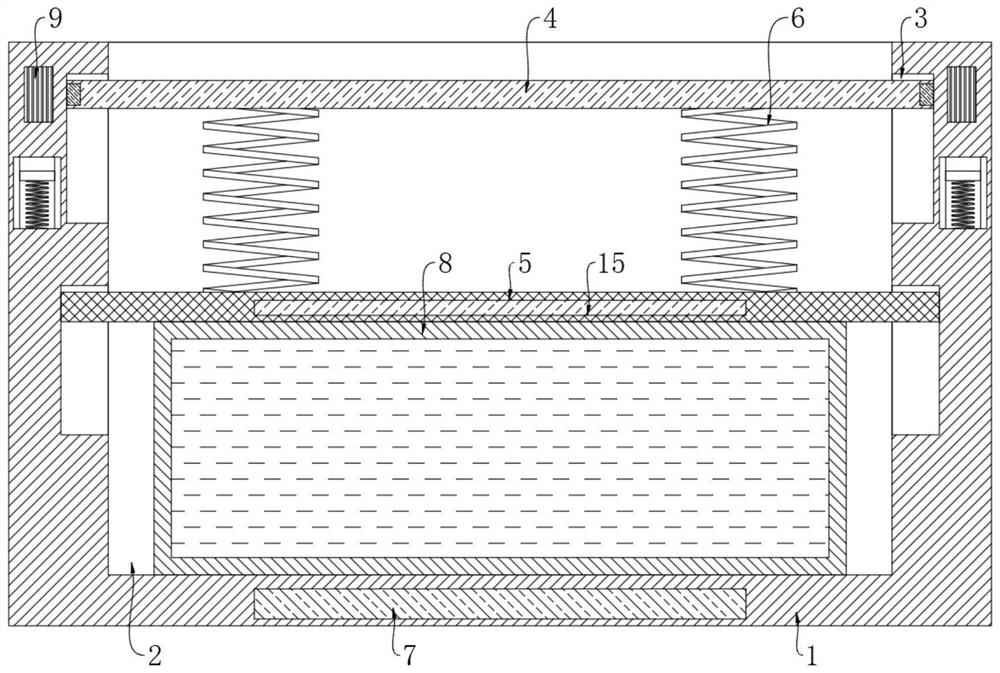

[0022] refer to image 3 The difference between this implementation and Embodiment 1 is that: the lower end surface of the movable plate 5 is provided with a permanent magnet plate 15, and the magnetic pole of the side opposite to the electromagnet 7 of the permanent magnet plate 15 is the same.

[0023] When the magnetic field intensity of the electromagnet 7 changed, the magnetic repulsion between the electromagnet 7 and the permanent magnet plate 15 also changed, and then the compressive force that the shock absorbing spring 6 was subjected to also changed, and then the shock absorbing spring 6, The characteristics of the shock absorber composed of the movable plate 5, the elastic air bag 8 and the magnetorheological fluid can be changed more obviously. For some working equipment with a larger vibration amplitude, the shock absorber effect is more obvious, thereby improving the applicability of the device. sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com