Fully-oxidizing oxygen injection calcining equipment for zinc oxide production

A zinc oxide, calcining technology, applied in lighting and heating equipment, maintenance of heating chamber, waste heat treatment, etc., can solve problems such as affecting the passage of oxygen, inconvenient to replace the filtrate and activated carbon layer, clogging, etc., to avoid the effect of impurity clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

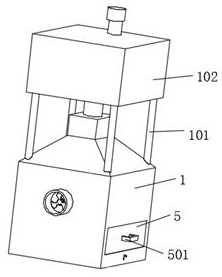

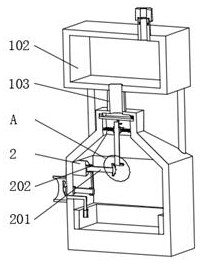

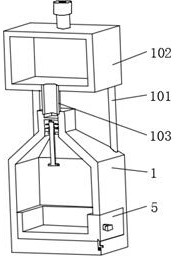

[0040] Example: Reference Figure 1-8 The shown oxygen injection calcination equipment for fully oxidized zinc oxide production includes a filter box 1, which is any metal box in the prior art.

[0041] Four support rods 101 are fixedly installed on the top of the filter box 1, and the same calcination box 102 is fixedly installed on the top of the four support rods 101, and the support rods 101 can be any vertical type in the prior art A rod structure, such as a metal rod, is fixed by welding to the bottom of the calciner box 102 .

[0042] The same connecting pipe 103 is fixedly installed on the side where the filtering box 1 and the calcining box 102 are close to each other, and the filtering box 1 communicates with the calcining box 102 and the connecting pipe 103, and the A motor 2 is fixedly installed on the inner wall of one side of the filter box body 1, and the output end of the motor 2 is fixedly installed with a rotating shaft 201 through a coupling, and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com