Method and system for capturing CO2 by absorption method

An absorption method, CO2 technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of increasing steam energy consumption, not considering regeneration energy consumption, and not conducting in-depth investigations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

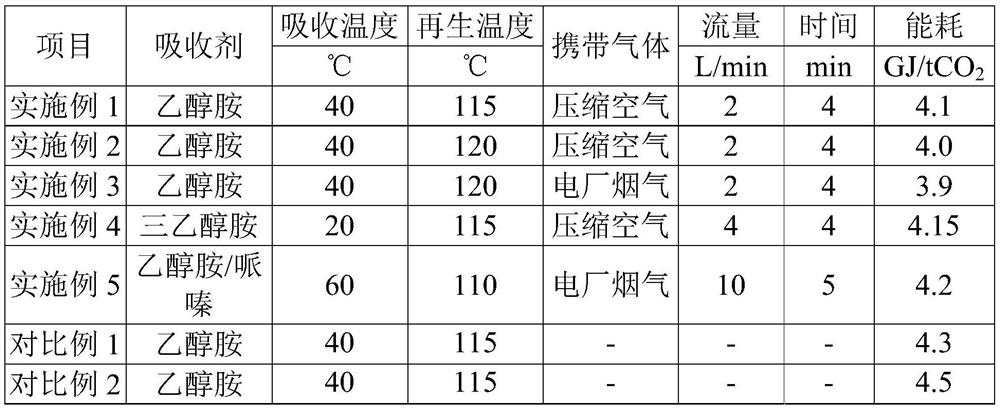

Embodiment 1

[0052] 1) Get 100L of 30% by weight ethanolamine solution and pass it into CO 2 capture system, with 12 vol% CO 2 The flue gas phase contact (ethanolamine solution with CO 2 The mass ratio of the flue gas is 3:1), and the CO 2 Absorption and capture of decarbonized flue gas and absorption rich liquid; online monitoring of the conductivity of the absorption rich liquid, and according to the fitting equation between the concentration of the absorbent and the conductivity, the concentration of ethanolamine in the ethanolamine solution is controlled to meet the CO 2 absorption and capture;

[0053] 2) Pass compressed air (flow rate: 2L / min, contact time: 4min) into regeneration tower for desorption regeneration, contact temperature is 115°C, contact pressure is 0.18MPa; absorb lean liquid and desorb gas, desorb gas CO 2 The content is more than 98% by volume;

[0054] 3) Adjust the pressure of the regeneration tower to restore the pressure of the regeneration tower to the pre...

Embodiment 2

[0056] 1) Get 100L of 30% by weight ethanolamine solution and pass it into CO 2 capture system with 12 vol% CO 2 The flue gas phase contact (ethanolamine solution with CO 2 The mass ratio of the flue gas is 3:1), and the CO 2 Absorption and capture; get decarbonized flue gas and absorb rich liquid;

[0057] 2) Pass compressed air (flow rate 2L / min, passage time 4min) into the regeneration tower for desorption regeneration at a temperature of 120°C and a pressure of 0.2MPa; obtain the poor absorption liquid and desorption gas; monitor the conductivity of the poor absorption liquid on-line, And according to the fitting equation between the concentration of the absorbent and the conductivity, the concentration of ethanolamine in the ethanolamine solution is controlled to meet the CO 2 Absorption and capture; desorption of CO in the gas 2 The content is more than 98% by volume;

[0058] 3) Adjust the pressure of the regeneration tower to restore the pressure of the regenerati...

Embodiment 3

[0060] 1) Get 100L of 30% by weight ethanolamine solution and pass it into CO 2 capture system with 12 vol% CO 2 Flue gas contact (ethanolamine solution with CO 2 The mass ratio of the flue gas is 3:1), and the CO 2 Absorption and capture of decarbonized flue gas and absorption rich liquid; online monitoring of the conductivity of the absorption rich liquid, and according to the fitting equation between the concentration of the absorbent and the conductivity, the concentration of ethanolamine in the ethanolamine solution is controlled to meet the CO 2 absorption and capture;

[0061] 2) Pass the flue gas of the power plant (flow rate 2L / min, feed time 4min) into the regeneration tower for desorption and regeneration at a temperature of 120°C and a pressure of 0.2MPa; absorb lean liquid and desorption gas, and desorb CO in the gas 2 The content is more than 98% by volume;

[0062] 3) Adjust the pressure of the regeneration tower to restore the pressure of the regeneration t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com