Food processing crushing and stirring device with screening function

A technology of food processing and stirring device, which is applied in the direction of sieve, grid, solid separation, etc., can solve the problems of inability to guarantee the quality of food raw materials, inability to guarantee the quality of finished food products, and inability to guarantee the degree of pulverization of food raw materials, etc. The effect of increasing efficiency, convenient and fast cutting, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

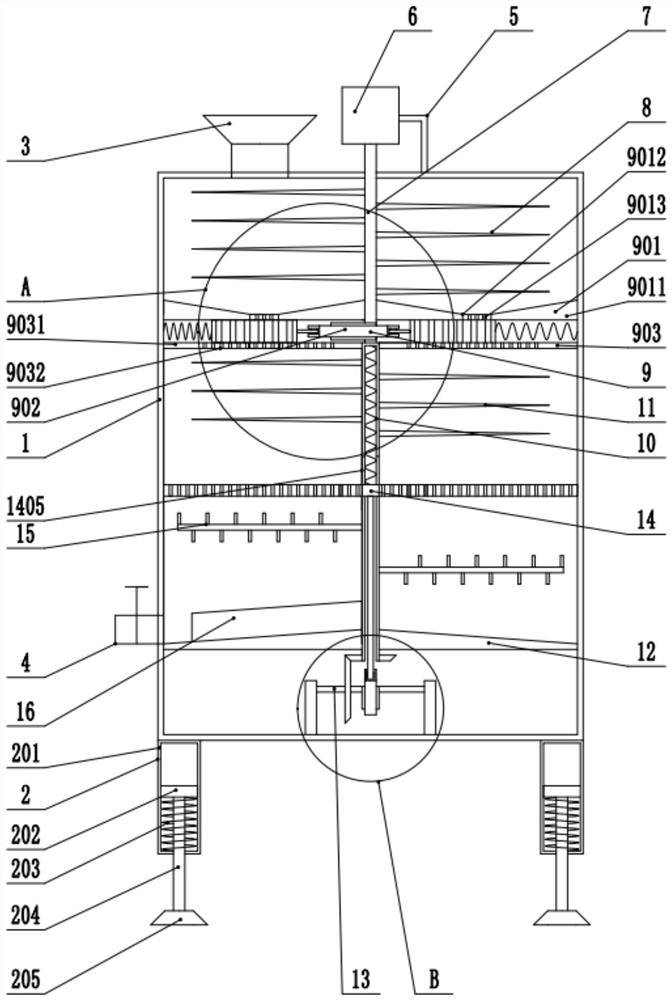

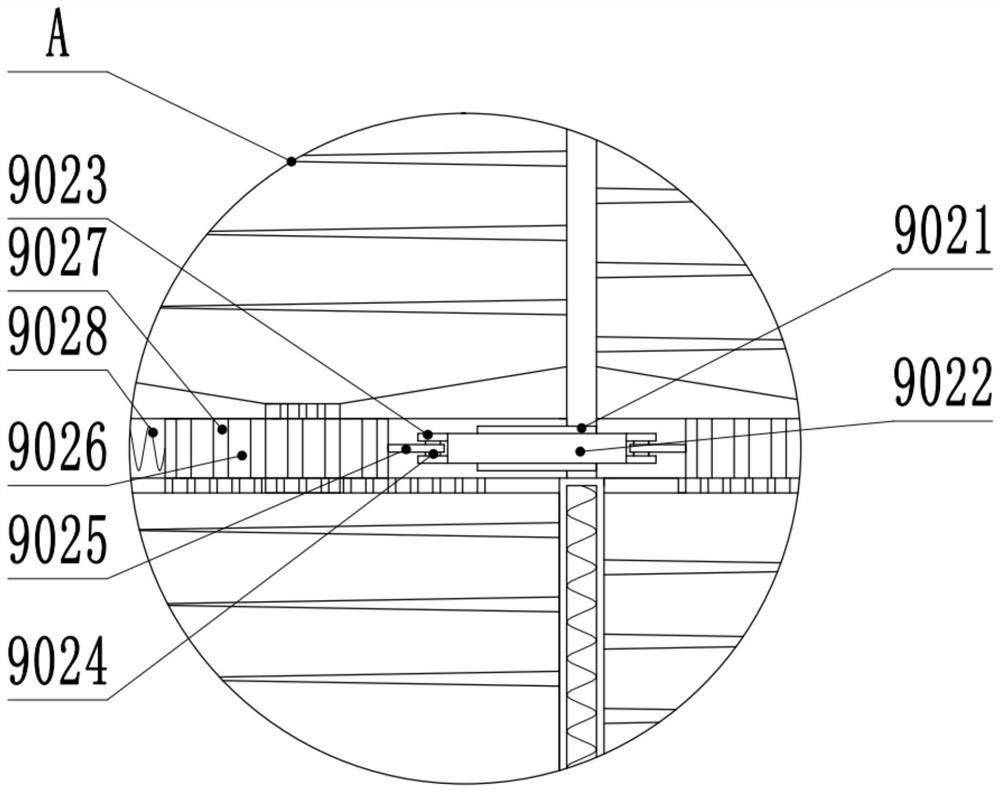

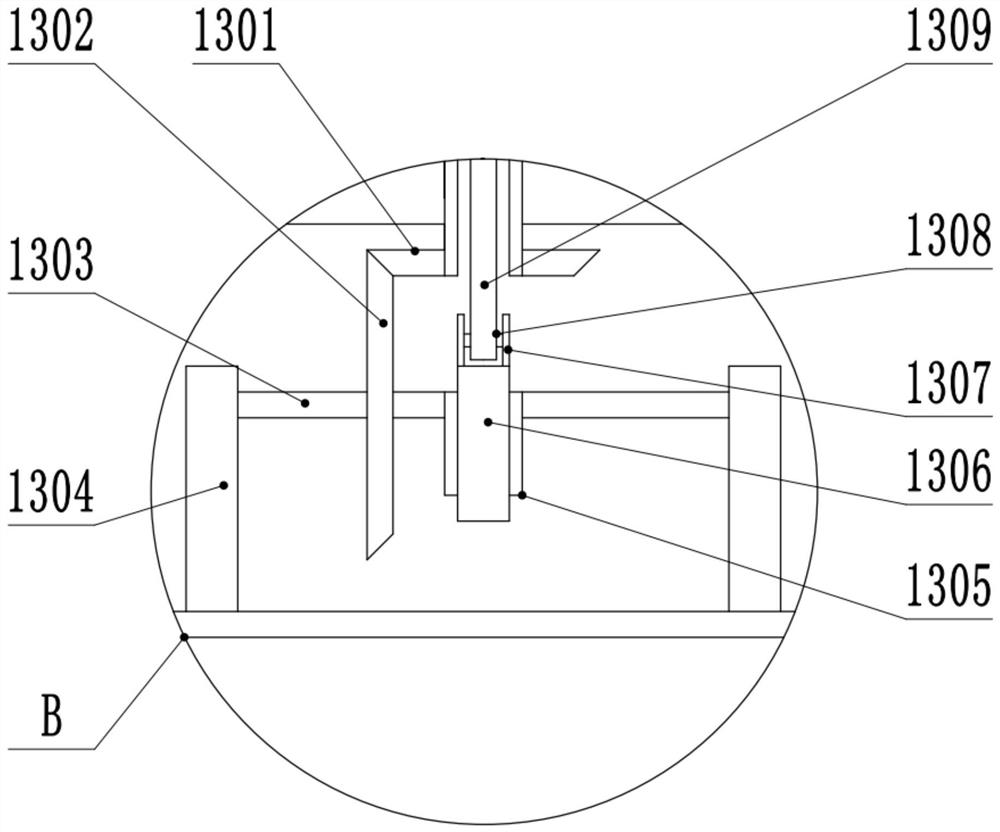

[0024] see Figure 1-4 , a crushing and stirring device for food processing with a screening function, comprising a box body 1, the lower surface of the box body 1 is fixedly connected to the shock absorbing mechanism 2, the upper surface of the box body 1 is fixedly connected to the feeding port 3, and the side of the box body 1 is fixed Connect the discharge port 4, the outer top of the box body 1 is fixedly connected to the motor bracket 5, the motor bracket 5 is fixedly connected to the motor 6, the output shaft of the motor 6 is fixedly connected to the rotating shaft 7, and the rotating shaft 7 is fixedly connected to the crushing mechanism 9 and several first crushing The blade 8, the lower end of the rotating shaft 7 is fixedly connected to the rotating sleeve 10, the rotating sleeve 10 is fixedly connected to several second pulverizing blades 11 and the stirring rod 15, the partition 12 is fixedly connected to the inside of the box body 1, and the rotating sleeve 10 is...

Embodiment 2

[0033] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the screening mechanism 14 includes a slider 1401, the slider 1401 is slidably connected to the rotating sleeve 10, and the rotating sleeve 10 is provided with a sliding groove 1405, The slider 1405 is fixedly connected to two connecting blocks 1402 , the side of the connecting block 1402 away from the slider 1401 is fixedly connected to the sieve plate 1403 , and the second spring 1404 is fixedly connected between the slider 1401 and the rotating sleeve 10 .

[0034] During the implementation of the present invention, the food raw materials to be processed are first put into the box body 1 through the feeding port 3, and then the motor 6 is turned on, and the rotation of the output shaft of the motor 6 will drive the rotation of the rotating shaft 7, and then the first crushing blade 8 will be driven. Rotate, so that the food material can be crushed to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com