A flexible lens gas mask lens and cover assembly production line

A gas mask and cover body technology, applied in assembly machines, manufacturing tools, dry gas arrangement, etc., can solve problems such as slow assembly speed, inability to guarantee the consistency of manual assembly products, and adhesives affecting product appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

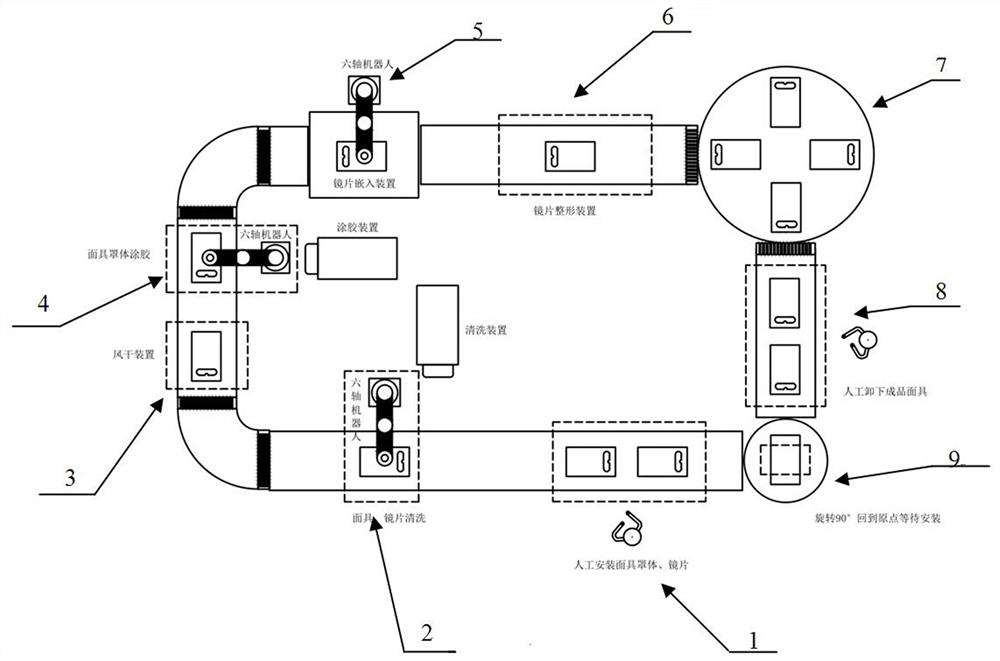

[0026] The invention is a production line for automatic assembly of flexible lens gas mask lens and cover body, mainly composed of four modules: flexible lens and cover body cleaning primer module, cover body gluing module, lens and cover body assembly module, conveying control module The system realizes the application of the cleaning agent and primer liquid of the lens and the cover, the uniform gluing of the groove of the cover, the assembly of the lens and the cover after gluing, and the conveying and control system of the product at each station through the conveyor belt. The design of the anti-gas mask lens adopts a flexible lens, and the assembly process of the lens and the mask body of the gas mask adopts the automatic assembly of the lens and the mask body of the gas mask, which is formed by adhesive bonding. The details are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com