Slicing and canning device for manufacturing yellow peach cans

A technology for canning and dicing yellow peaches, which is applied in packaging, food packaging, transportation and packaging, and can solve problems such as low work efficiency, pollution of yellow peaches, and impact on food quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

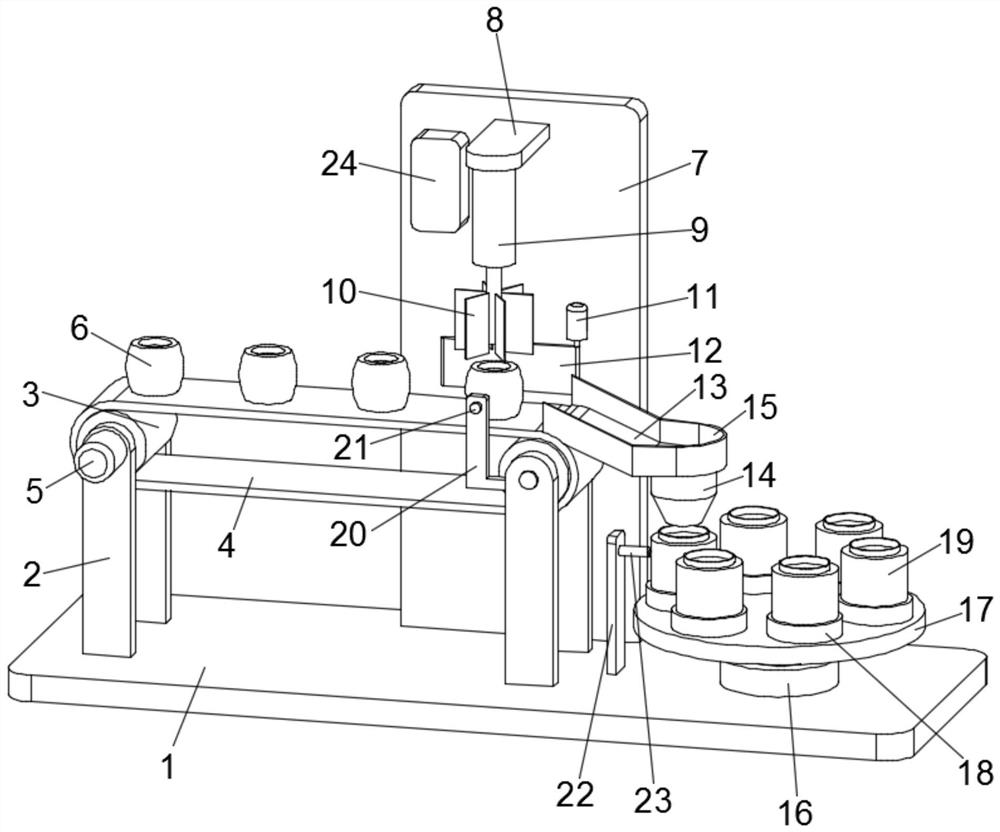

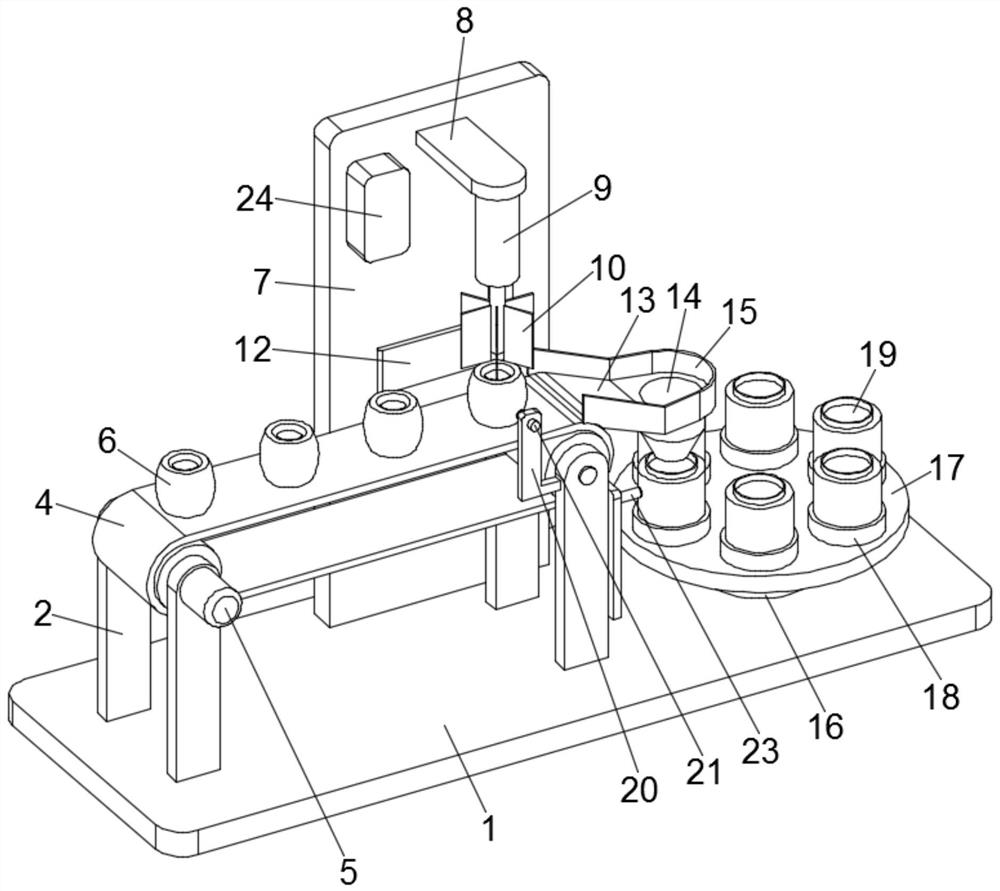

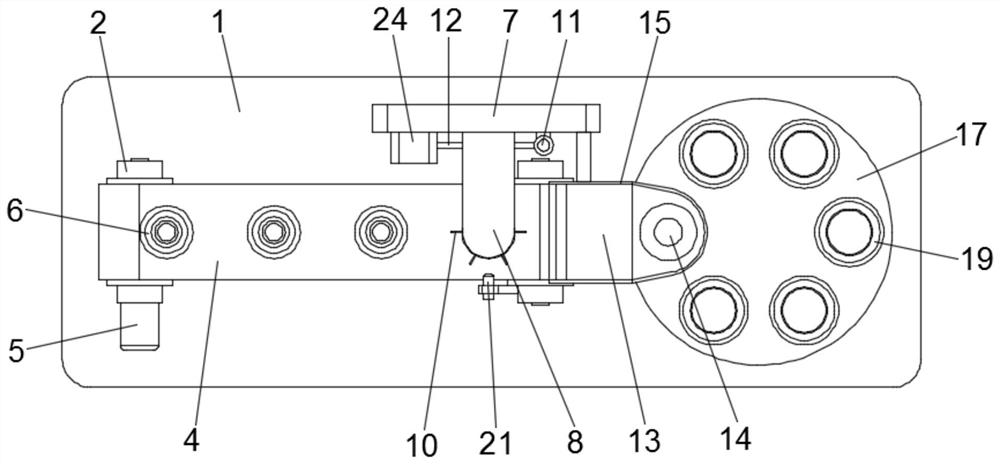

[0025] see Figure 1-3 , a canning device for yellow peach canning, comprising a base 1 and a side plate 7, the side plate 7 is vertically and fixedly installed on the base 1, and a support frame 2 is fixedly installed on the base 1, the On the support frame 2, a drum 3 is rotated, and the rotation sleeve on the drum 3 is provided with a conveyor belt 4 for conveying yellow peaches 6, and a transmission motor 5 for driving the drum 3 is installed on the support frame 2 on one side;

[0026] A telescopic rod 9 is fixedly installed on the side plate 7 through a fixed plate 8, the telescopic rod 9 is located directly above the conveyor belt 4, and a plurality of blades 10 are uniformly distributed around the end of the telescopic rod 9;

[0027] The output end of the conveyor belt 4 is provided with a material guide plate 13, and the material guide plate 13 is fixed on the side plate 7, and the bottom of the material guide plate 13 is provided with a funnel 14; a turntable 16 is ...

Embodiment 2

[0037] A device for cutting and filling canned yellow peaches, comprising a base 1 and a side plate 7, the side plate 7 is vertically and fixedly installed on the base 1, and a support frame 2 is fixedly installed on the base 1, and the support On the frame 2, a drum 3 is rotated, and the drum 3 is rotated to be provided with a conveyor belt 4 for conveying yellow peaches 6, and a transmission motor 5 for driving the drum 3 is installed on the support frame 2 on one side;

[0038] A telescopic rod 9 is fixedly installed on the side plate 7 through a fixed plate 8, the telescopic rod 9 is located directly above the conveyor belt 4, and a plurality of blades 10 are uniformly distributed around the end of the telescopic rod 9;

[0039] The output end of the conveyor belt 4 is provided with a material guide plate 13, and the material guide plate 13 is fixed on the side plate 7, and the bottom of the material guide plate 13 is provided with a funnel 14; a turntable 16 is also instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com