High-dielectric and low-loss material based on capacitor-inductor synergistic effect and preparation method

A synergistic effect, capacitive-inductive technology, applied in the field of materials, can solve problems such as high dielectric constant and high impedance matching characteristics, and achieve the effects of large-scale production, reduced loss, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

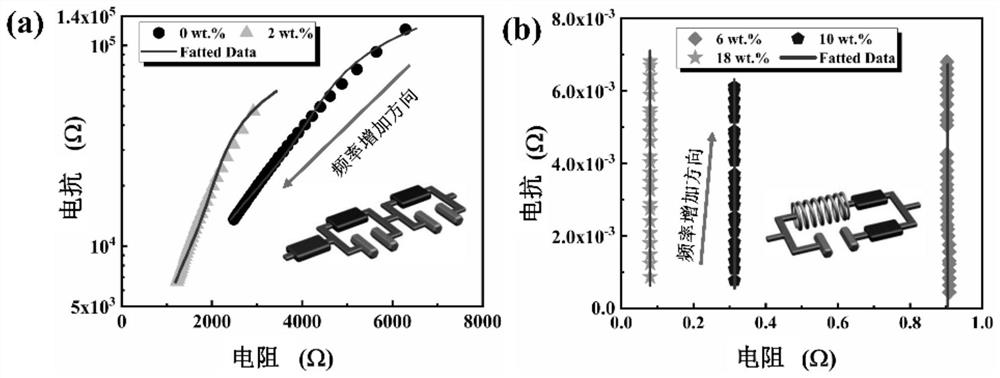

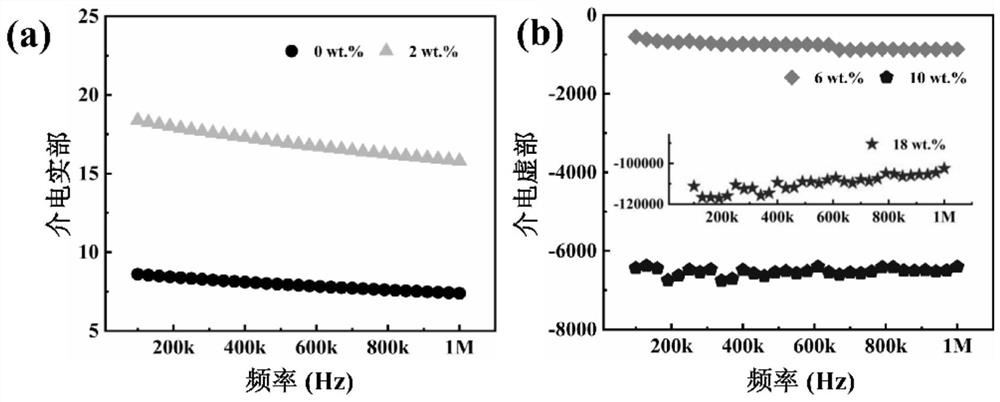

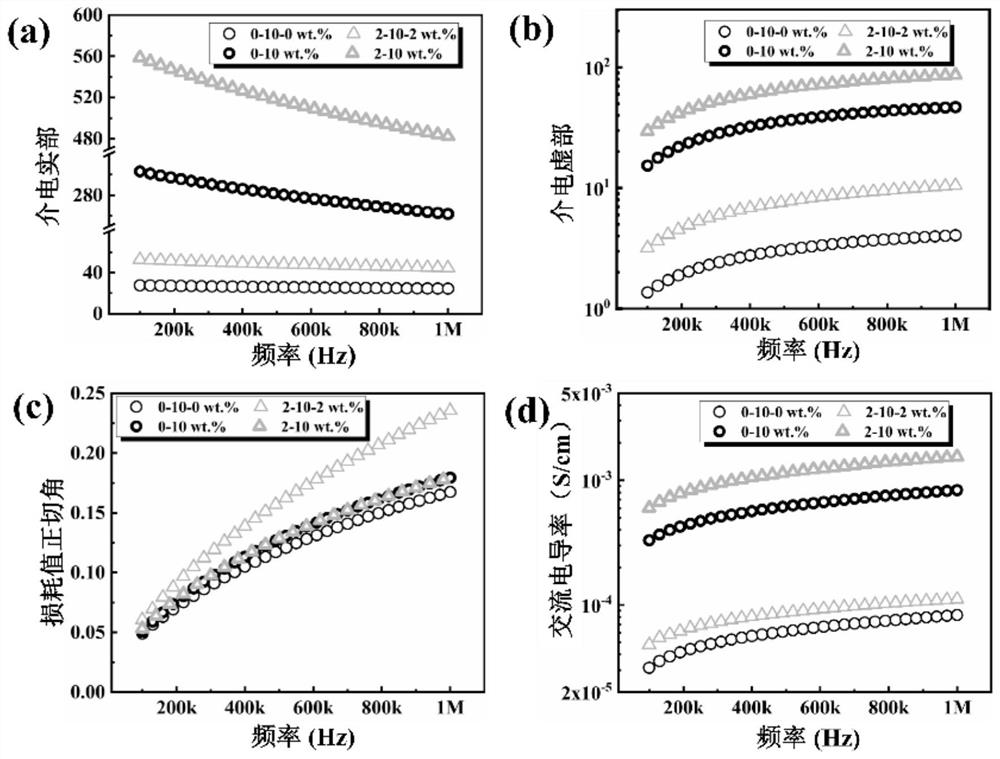

[0029] Weigh 0.45g of polyvinylidene fluoride, pour it into a hot press for molding, set the pressure to 20MPa, set the hot pressing temperature to 100°C, and set the holding time to 5min; then pour 0.45g of graphene with a mass fraction of 10wt.% Mix the powders, and prepare a 0-10wt.% double-layer composite material according to the above-mentioned hot pressing process.

Embodiment 2

[0031] Weigh 0.45g of mixed powder with a graphene mass fraction of 2wt.%, pour it into a hot press for molding, set the pressure to 20MPa, set the hot pressing temperature to 100°C, and set the holding time to 5min; then pour 0.45g of graphite The mixed powder with 10wt.% mass fraction of alkene is prepared according to the above-mentioned hot pressing process to prepare 2-10wt.% double-layer composite material.

Embodiment 3

[0033] Weigh 0.3g of polyvinylidene fluoride powder, pour it into a hot press for molding, set the pressure to 20MPa, set the hot pressing temperature to 100°C, and set the holding time to 5min; The mixed powder of .% is pressed and formed according to the above process, and finally 0.3g of polyvinylidene fluoride powder is poured into it, and a 0-10-0wt.% three-layer composite material is prepared after hot pressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com