MBR membrane assembly testing device

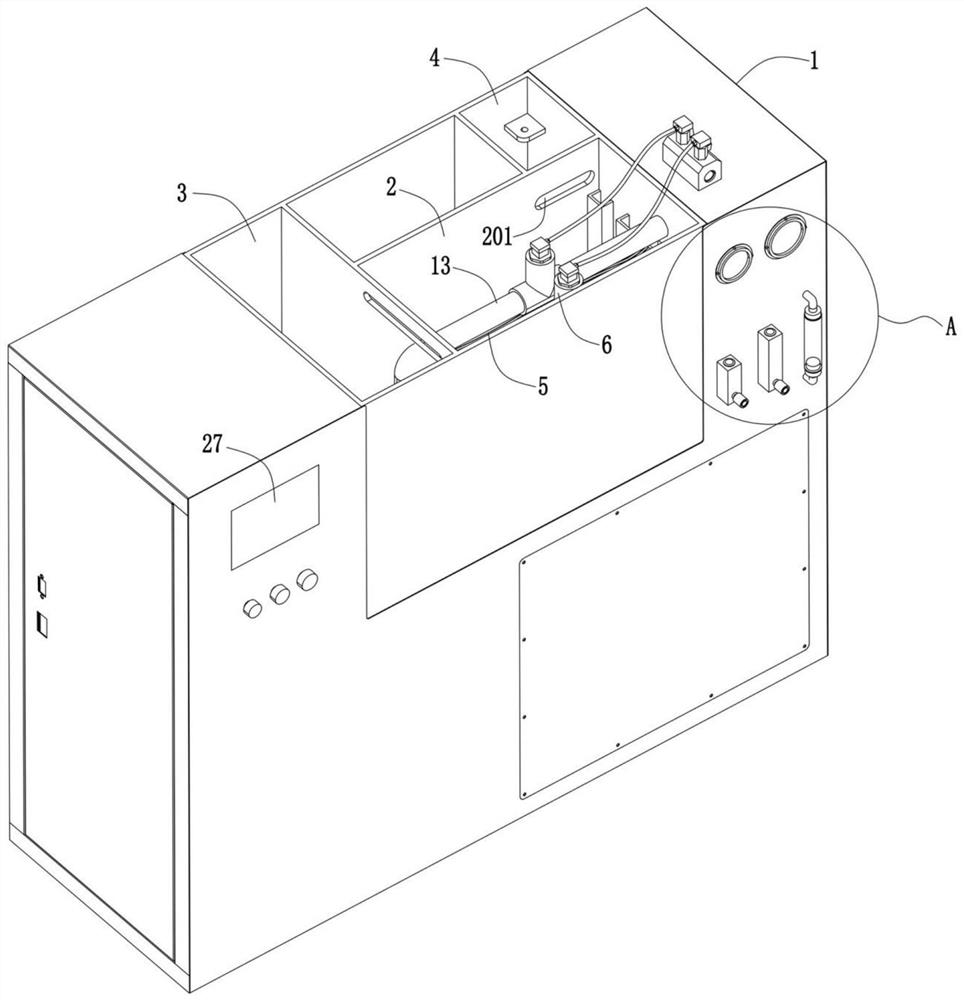

A test device and membrane module technology, which is applied in biological treatment devices, water treatment parameter control, special treatment targets, etc., can solve the problems of inconvenient disassembly, inaccurate results, and blockage of micropores, so as to ensure results and save human resources. , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] In this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiment 1. When sewage is stored in the sewage overflow pool 4, the water replenishment system participates in the water production process of the water production system at the same time;

[0048] Such as Figure 5 As shown, specifically, the water replenishment system includes a replenishment pipeline 20 whose two ends are connected to the sewage overflow pool 4 and the sewage pond 2 respectively, and a check valve 21 and a return pump 22 are sequentially connected to the replenishment pipeline 20. In the above settings , the sewage passes through the one-way valve 21 and is pumped into the sewage tank 2 by the return pump 22 along the replenishment pipeline 20. Due to the function of the one-way valve 21, the sewage can only overflow from the sewage along the replenishment pipeline 20 One side of the pool 4 flows to the sewage pool 2, so as to prevent the sewage in the sew...

Embodiment 3

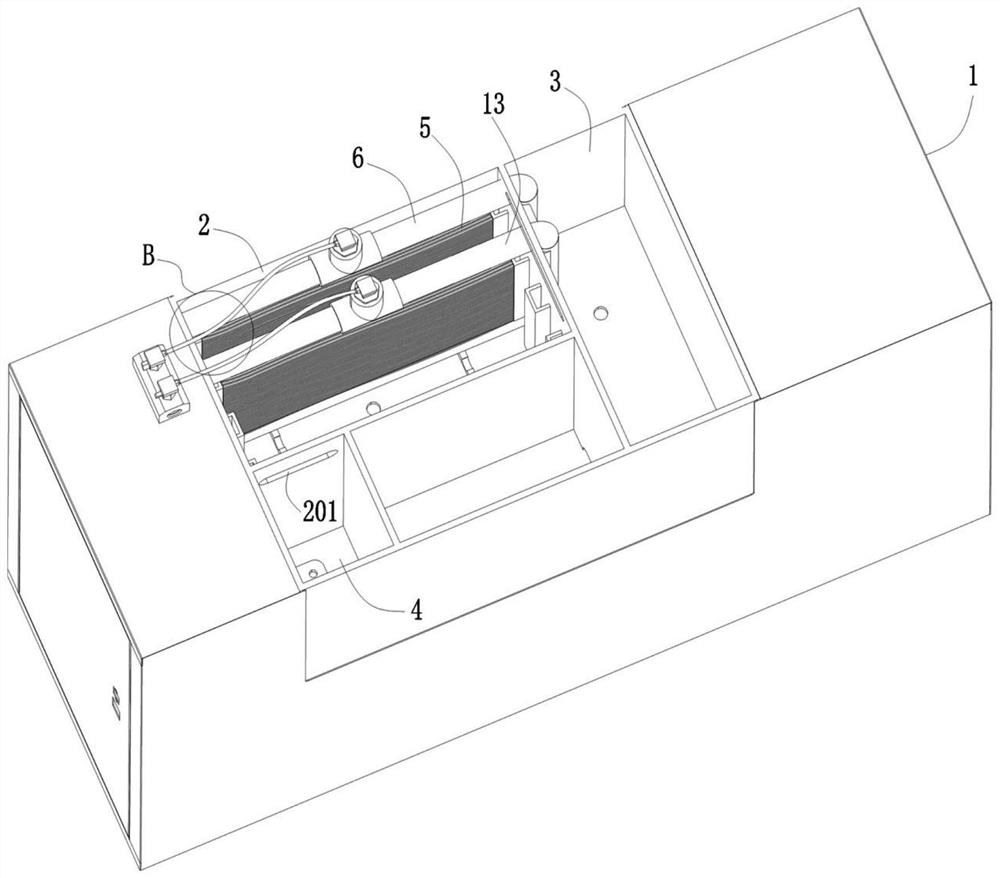

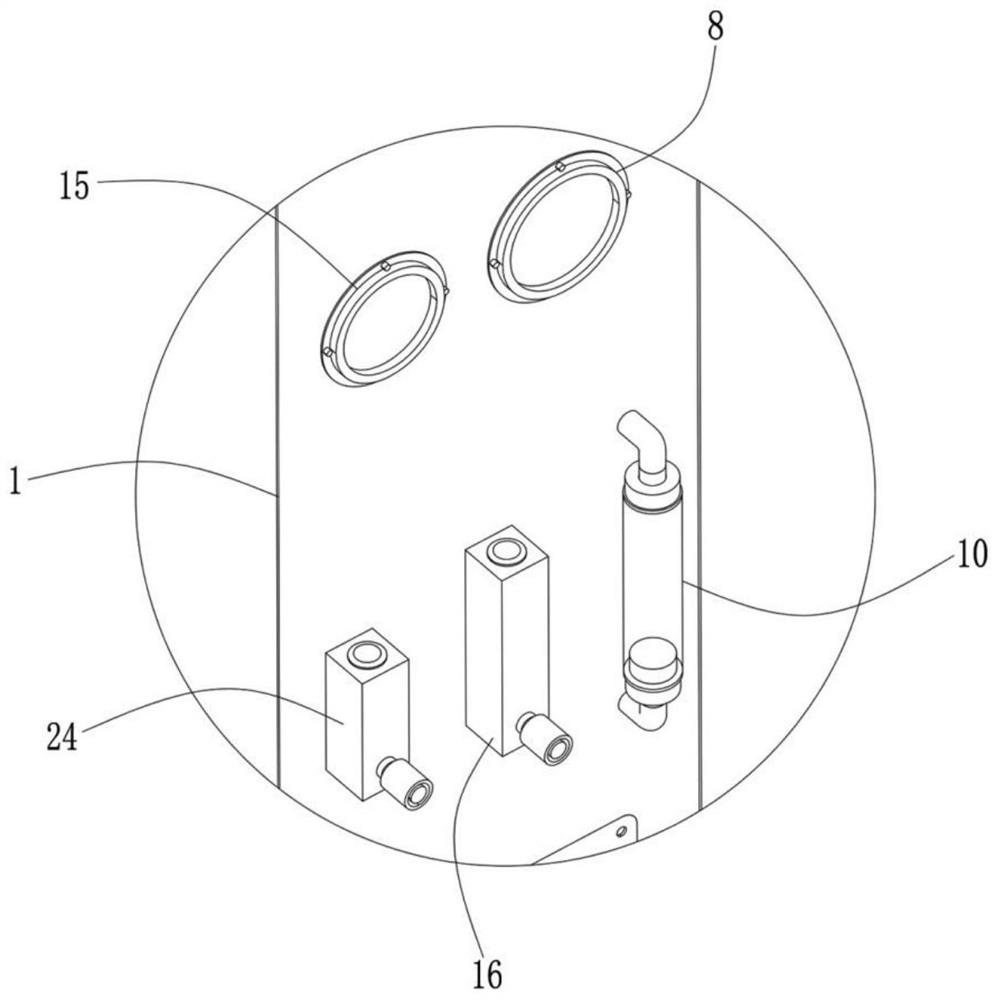

[0051] Such as image 3 with Figure 5 As shown, in this embodiment, one of the optimized designs is made on the basis of the above-mentioned embodiment 1. An aeration system is also connected to the sewage tank 2. The aeration system is controlled by the test control system 27. The aeration system includes two ends respectively. The aeration pipeline 23 communicated with the sewage tank 2 and an aeration pump 24 is also connected with an air flow meter 25 on the aeration pipeline 23. Similarly, the air flow meter 25 is fixed on the outer surface of the main box body 1, It is convenient for the tester to intuitively understand the real-time aeration value during the test operation;

[0052] Such as Figure 5 As shown, the aeration system participates in the water production operation at the same time, the aeration pump 24 is controlled by the test control system 27, and the aeration pump 24 can pump the external air into the sewage tank 2 along the aeration pipeline 23, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com