Ultrasonic vibration combined type well washing device and well washing method

An ultrasonic and composite technology, applied in wellbore/well components, vibration generating devices, wellbore/well valve devices, etc., can solve the problems of flowback fluid falling, low well cleaning efficiency, and incomplete scale removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

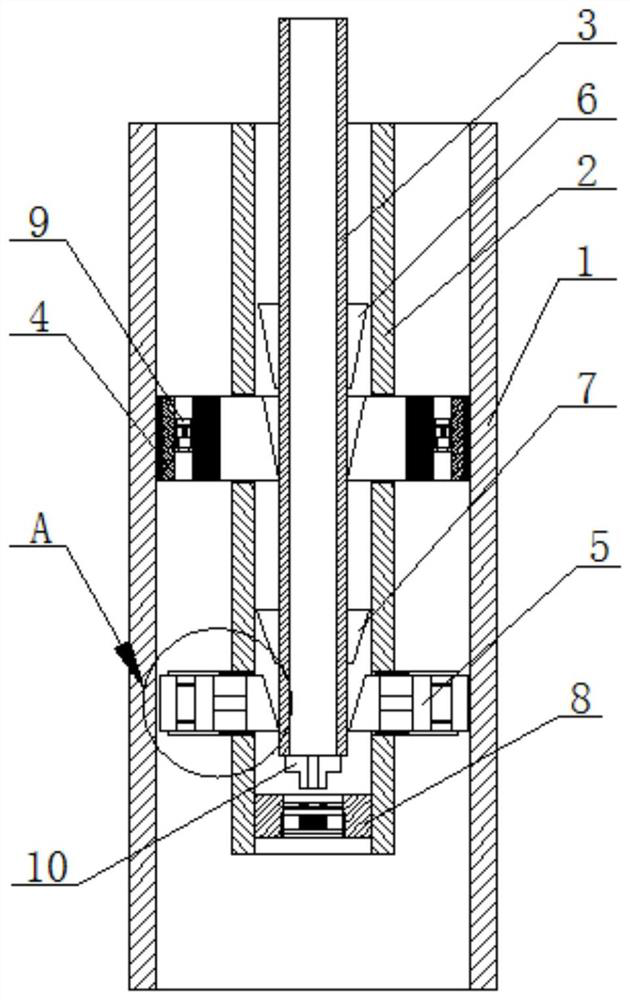

[0053] Such as figure 1 The ultrasonic vibration composite well cleaning device includes an inner casing 2 arranged in the liquid return pipe 1 in the well, a well flushing pipe 3 arranged in the inner casing 2 and extending to the outside of the liquid return pipe 1 ;

[0054] The liquid return pipe 1 is lowered into a water supply well or a geothermal well for collecting hot water in the well, and the inner casing 2 is the base pipe of a composite well cleaning device, which is lowered during well cleaning to avoid affecting the production process. When it is hot, the efficiency of heat extraction is reduced; the well-flushing pipe is used to inject well-flushing fluid into the hot liquid pipe to clean the liquid return pipe;

[0055] The upper part of the inner casing 2 is covered with a packer assembly 4, and the end of the packer assembly 4 connected to the inner casing 2 extends into the inner casing 2; Liquid through holes 405, each liquid return through hole 405 is p...

Embodiment 2

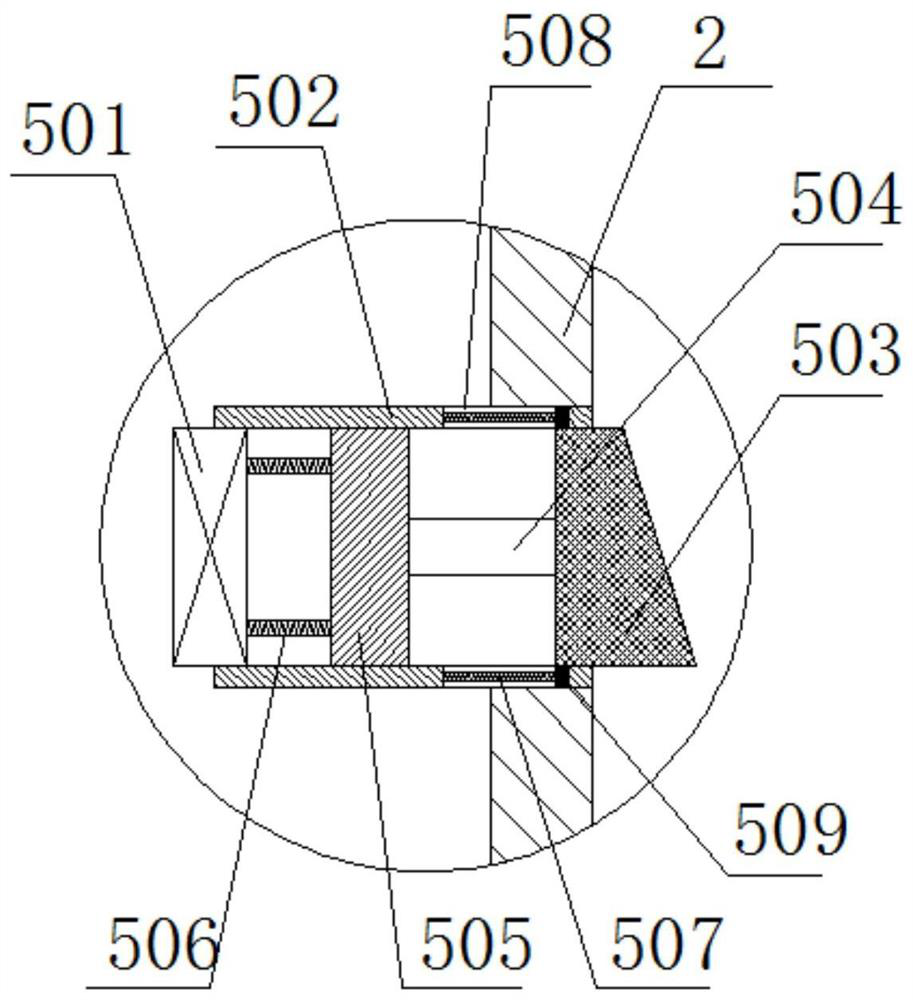

[0062] On the basis of Embodiment 1, in order to ensure that the well flushing pipe is in the downward process, driving the support head of the ultrasonic vibration assembly can make the ultrasonic vibrator in the ultrasonic vibration assembly 5 closely interfere with the inner wall of the liquid return pipe, and the fixation is stable, such as image 3 The ultrasonic vibration assembly 5 includes parallel base pipes 502 fixedly connected to both sides of the inner sleeve 2 and communicated with the inner sleeve 2, one end of the parallel base pipes 502 is provided with an ultrasonic vibrator 501, and the ultrasonic vibrator 501 is connected to the device. The slider 505 in the parallel base pipe 502 is fixedly connected by a compression spring 506, and the slider 505 is connected with the super wave vibrator by a compression spring 506 to ensure that the ultrasonic vibrator is pushed to contact with the inner wall of the liquid return pipe with a certain The cushioning and adj...

Embodiment 3

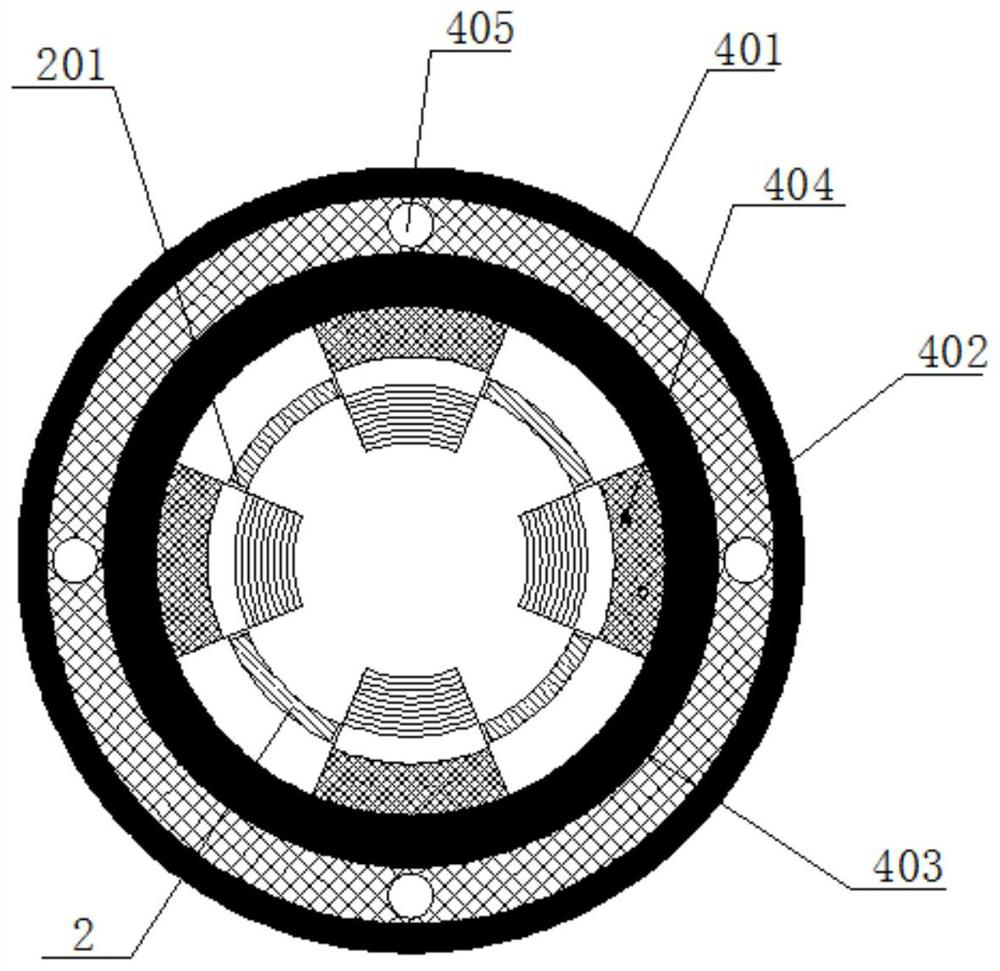

[0066] On the basis of Example 1 or Example 2, it is ensured that when the well flushing pipe goes down, the annular space between the liquid return pipe and the inner casing can be fully sealed and sealed, and at the same time, it is ensured that when the device is not lowered, no It will affect the efficiency of the liquid return pipe, such as figure 2The packing assembly 4 includes an outer sealing rubber ring body 401 in sealing contact with the inside of the liquid return pipe 1, a base ring body 402 set in the outer sealing rubber ring body 401, and a rubber expansion ring body set in the base ring body 402. The ring body 403 is fixedly connected to a plurality of trapezoidal tiles 404 in the rubber expansion ring body 403; the end of the slope of each trapezoidal tile 404 extends to the inner casing 2 through the through hole 201 provided on the inner casing 2 During operation, the outer sealing rubber ring body 401 can be in sealing contact with the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com