Recycling and reuse process of desulfurization wastewater based on composite membrane system

A desulfurization wastewater, composite membrane technology, applied in membrane technology, semi-permeable membrane separation, water/sewage treatment, etc., can solve the problems of reducing the total wastewater recovery rate and increasing the operating cost of the zero-discharge system, and improve the water recovery rate. , Excellent operational stability, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0055] The third embodiment of the present invention provides an application of the above-mentioned modified ceramic membrane in the treatment of desulfurization wastewater.

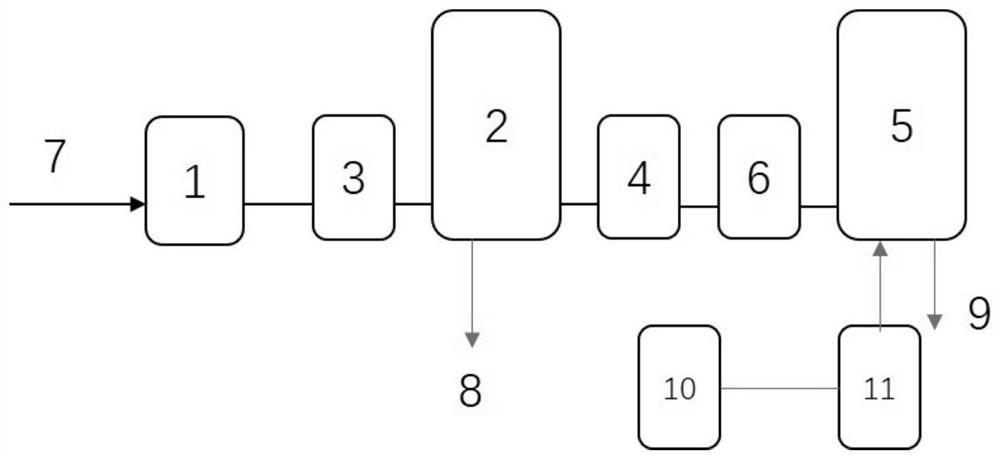

[0056] The fourth embodiment of the present invention provides a composite membrane system, including a ceramic membrane filtration unit and a reverse osmosis membrane filtration unit connected in sequence, and the ceramic membrane used in the ceramic membrane filtration unit is the above-mentioned modified ceramic membrane.

[0057] In one or more examples of this embodiment, a first filter is included, and the outlet of the first filter is connected to the inlet of the ceramic membrane filtration unit.

[0058] In this series of embodiments, the first filter is a laminated filter.

[0059] In this series of embodiments, a booster pump is provided between the first filter and the ceramic membrane filter unit, and the outlet of the booster pump is connected to the inlet of the ceramic membrane filter uni...

Embodiment 1

[0078] Soak the ceramic membrane with a cut-off pore size of 50nm in 3% hydrochloric acid for 12 hours, then apply ultrasound and continue cleaning for 1 hour. Then wash with desalinated water until the pH of the cleaning solution is not lower than 5.5. The treated ceramic membrane was then soaked in 1% Fe(NO 3 ) 3 , 0.1% Mn(NO 3 ) 2 and 0.1% Co(NO 3 ) 2 In the mixed solution, let stand for adsorption for 24 hours, wash with desalted water until it is colorless, put it into a muffle furnace for calcination after drying. The calcination process is to first raise the temperature to 500°C at 4°C / min, hold for 4 hours, then raise the temperature to 800°C at 2°C / min, hold for 2 hours, wash with 1% hydrochloric acid until colorless after cooling, and then wash with desalted water to pH Not less than 5.5, to obtain a modified ceramic membrane.

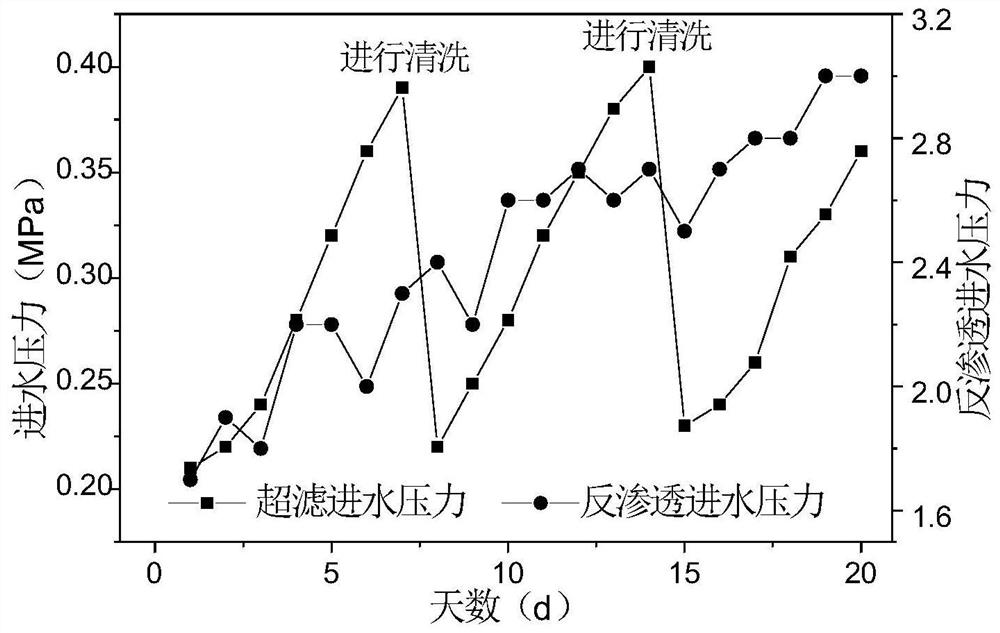

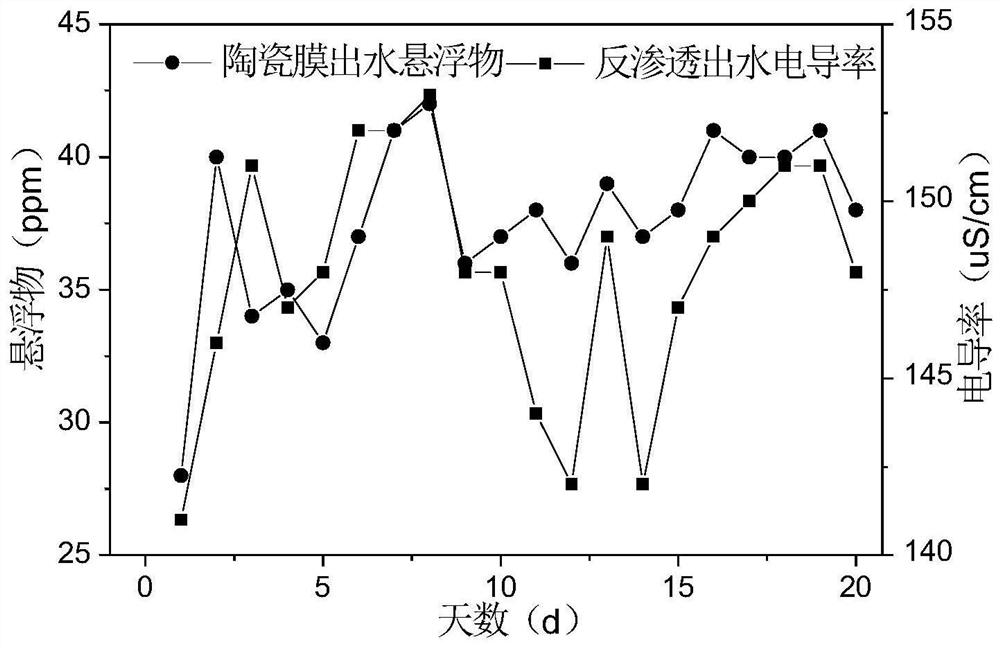

[0079] A composite membrane system, such as figure 1 As shown, it includes laminated filter 1, booster pump 3, ceramic membrane unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com