Online descaling device for fan

A fan and solenoid valve technology, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids, can solve the problem of inability to completely cover the inside of the fan, the inability to completely solve the fouling of the fan, and the easy fouling of the nozzle Blockage and other problems, to ensure long-term reliable operation, high power, and prevent the growth of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

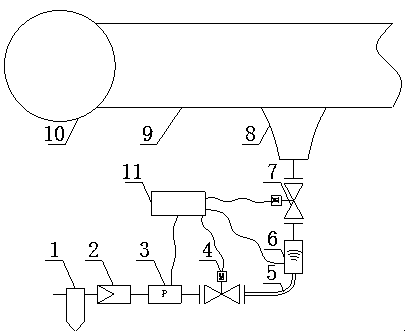

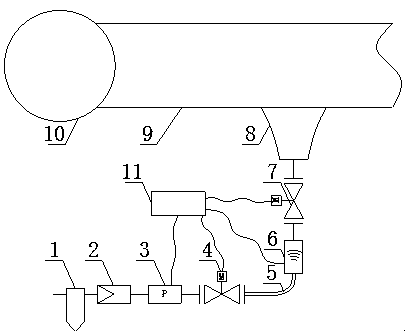

[0015] Such as figure 1 As shown, the fan online descaling device installed in the converter dust removal system of the steel plant provided in this embodiment includes: a filter 1, a pressure reducing valve 2, a pressure switch 3, a first solenoid valve 4, and a metal hose 5 , Acoustic wave generator 6, second solenoid valve 7, horn 8, controller 11. The online pipeline 9 of the converter dust removal system is connected to the air inlet of the fan 10, the filter 1, the pressure reducing valve 2, the pressure switch 3, the first solenoid valve 4, the metal hose 5, the acoustic wave generator 6, the second solenoid valve 7, The horns 8 are arranged and connected in sequence, and are connected by flanges of compressed air pipelines. The horns 8 are welded on the online pipeline 9 and face the inside of the online pipeline 9 . The controller 11 is respectively connected with the pressure switch 3 , the first solenoid valve 4 , the sound wave generator 6 and the second solenoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com