Automatic drill rod replacing device of tunnel anchor rod trolley

A technology of bolt trolley and drill rod, which is applied to the installation of bolts, mining equipment, earthwork drilling and mining, etc., and can solve problems such as poor economy, low efficiency, and increased tunnel construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described in conjunction with accompanying drawing and specific embodiment:

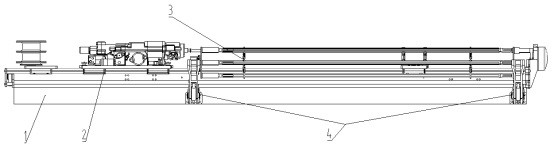

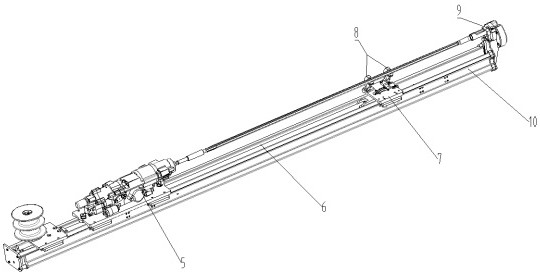

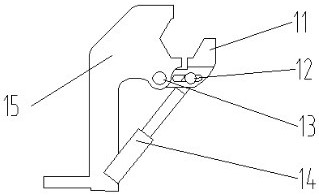

[0023] Such as Figure 1-9 As shown, an automatic drill rod changing device for a tunnel anchor trolley, the automatic drill rod changing device for a tunnel anchor trolley includes a propulsion beam bracket 1, a propulsion drilling mechanism 2, a drill rod warehouse 3, and a drill rod warehouse lift Up agency 4.

[0024] The propulsion beam bracket 1 is installed on the front end of the drill arm of the bolt trolley, and is mainly used to install the propulsion drilling mechanism 2 and the lifting mechanism 4 of the drill rod warehouse; the propulsion drilling mechanism 2 is installed on the On the propulsion beam bracket 1, there are mainly functions such as propulsion, drilling, and clamping. The propulsion drilling mechanism 2 includes a rock drill 5, a propulsion cylinder 6, a middle tray 7, a brazing manipulator 8, a front end top plate 9, a propulsion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com