Auxiliary leveling structure for mounting assembled cabinet

An installation and assembly technology, which is applied in the field of auxiliary flat structure for assembly cabinet installation, can solve the problems of reducing work efficiency, affecting workers' judgment, and needing to repeat measurement data, so as to increase utilization rate and avoid data errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

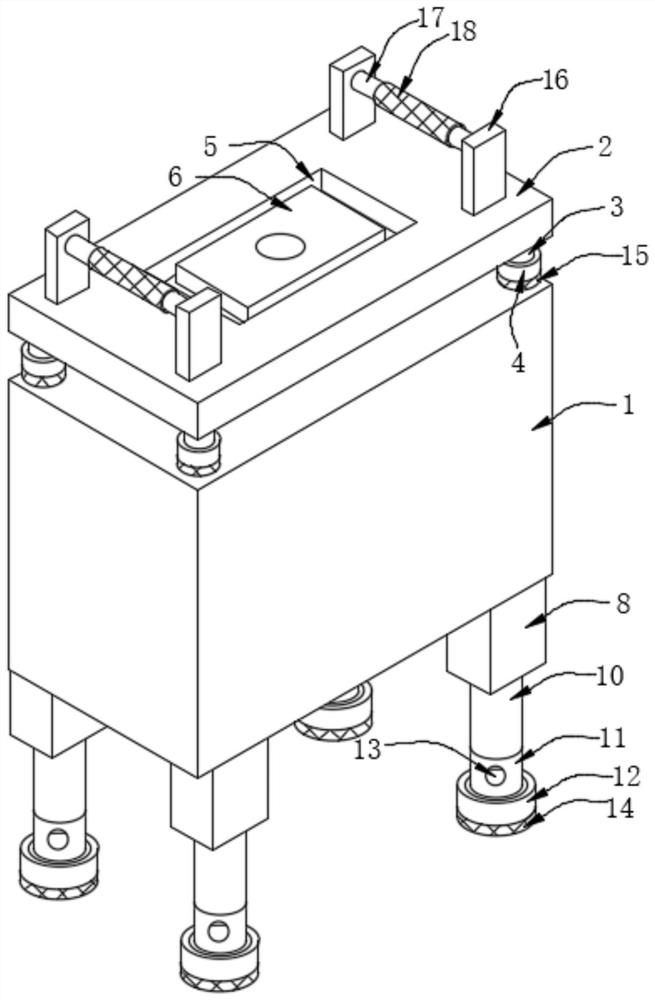

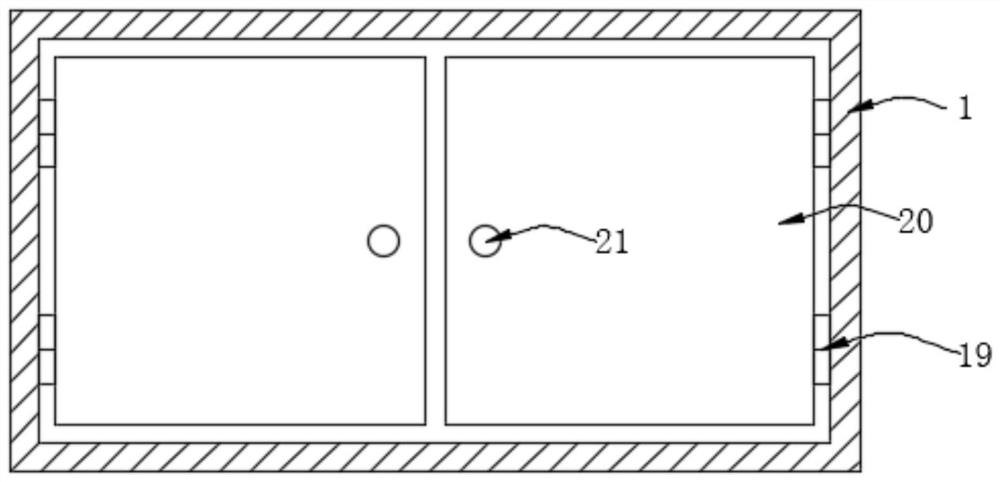

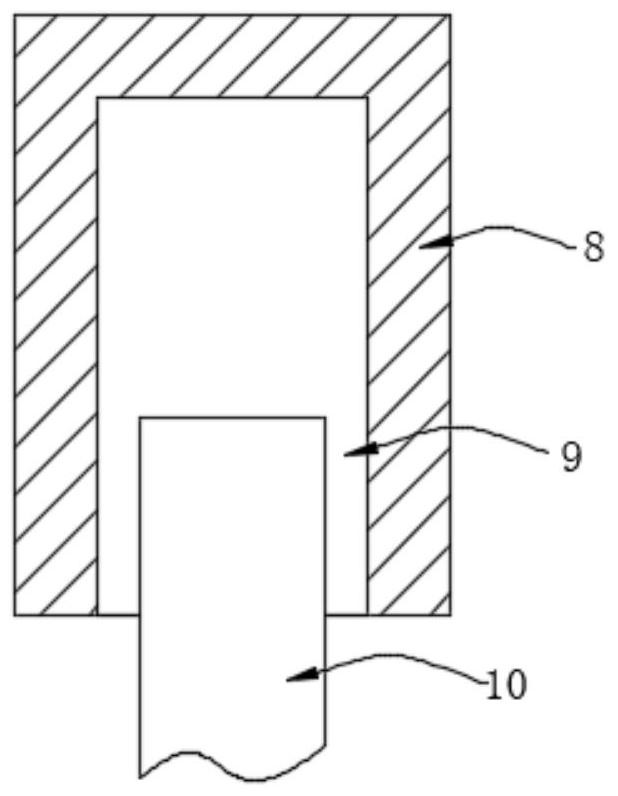

[0029] see Figure 1-6 , the present invention provides a technical solution: an auxiliary flat structure for assembly-type cabinet installation, including a first shell 1, a first plate 2 is arranged above the first shell 1, and the lower surface of the first plate 2 Four first rod bodies 3 are welded symmetrically to each other at the four corners, and one end of the first rod body 3 is welded with a second plate body 4, and the lower surface of the second plate body 4 is bonded with a protective pad 15, and the lower surface of the protective pad 15 is bonded On the upper surface of the first housing 1, the upper surface of the first plate body 2 is provided with a first groove 5, and the inner bottom wall of the first groove 5 is fixedly connected with the second housing 6, and the second housing 6 The upper surface is bonded with a cross mark 7, and the four corners of the lower surface of the first housing 1 are symmetrically welded with four square rods 8. The lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com