Woven-mesh-shaped valve repair clamp

A woven mesh and valve technology, applied in the field of medical devices, can solve the problems of insufficient fatigue strength, high manufacturing cost, fatigue fracture, etc., and achieve the effects of improving the success rate, reducing the overall weight, and prolonging the functional life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

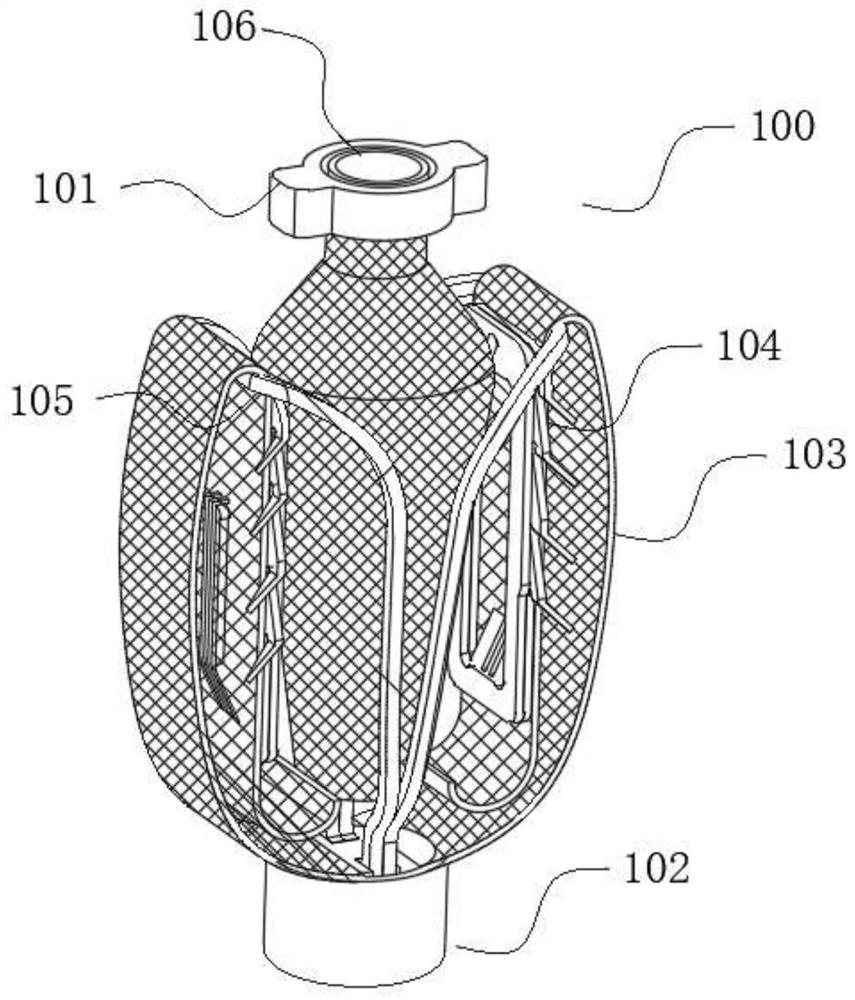

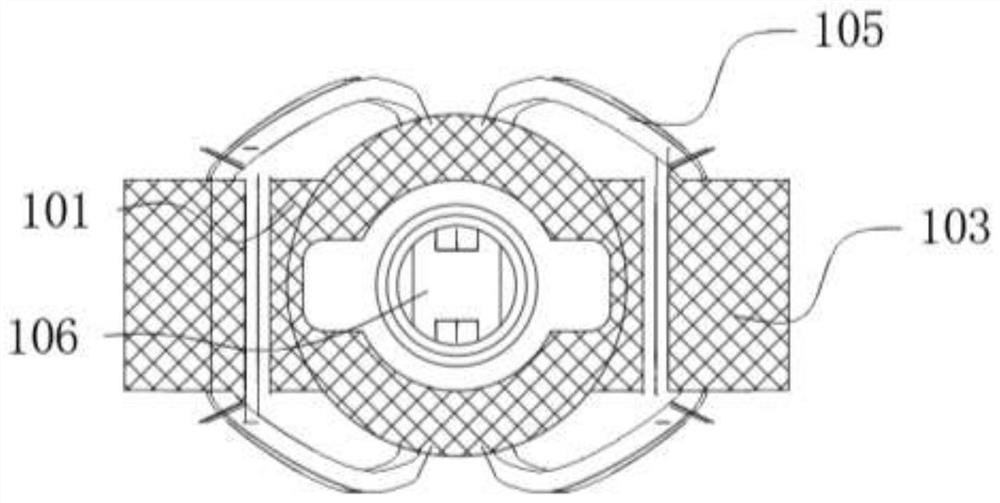

[0030] Such as Figure 1-9 As shown, the braided mesh valve repair clamp of this embodiment is used for valve repair treatment, which can be performed by "transseptal technique" (that is, inserting the catheter into the right femoral vein, up the inferior vena cava and into the Right atrium. Then the septum is punctured and the catheter is threaded into the left atrium) The repair jig is sent to the left atrium for repair work.

[0031] Specifically, the main body 100 of the braided mesh valve repair clip includes a braided mesh clip 103, a valve clip 104, a top seat 101, a base 102, and an auxiliary clamping bracket.

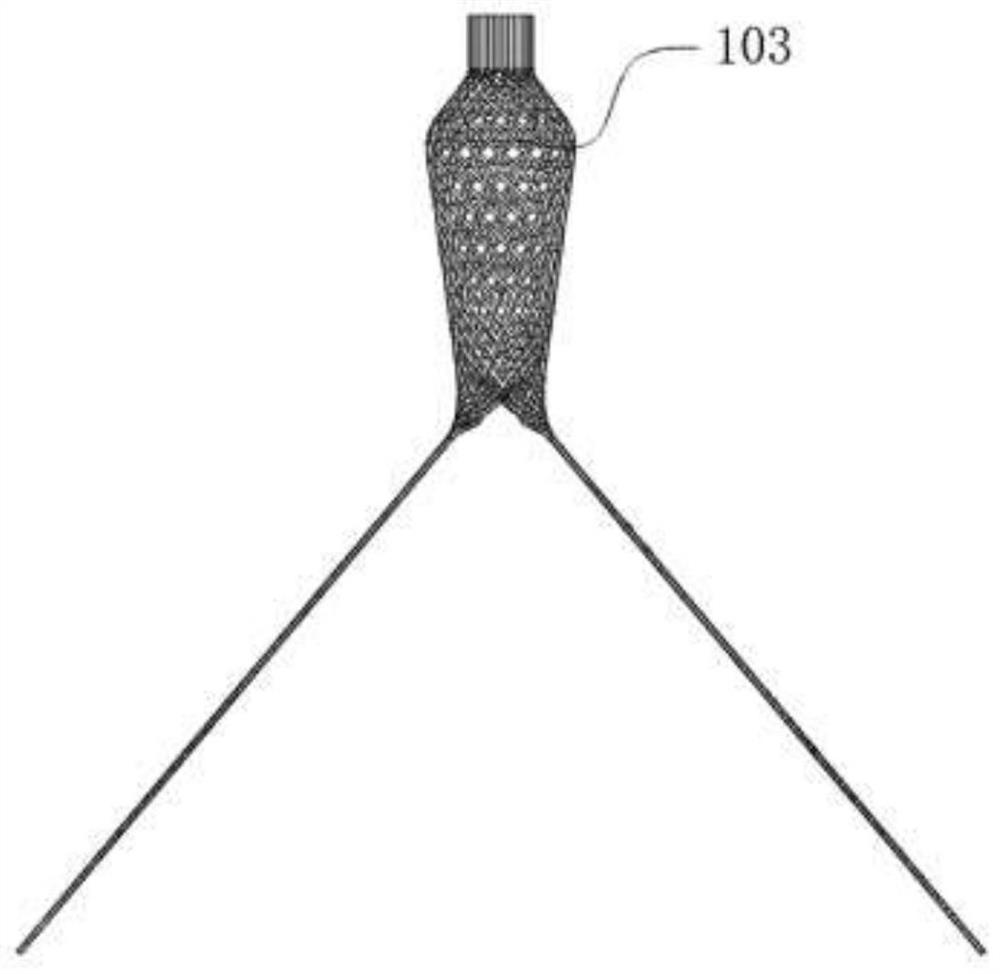

[0032] The braided net clip 103 is a braided mesh structure and has elasticity, including a column-shaped abutting column at the top and two clamping strips extending symmetrically against the bottom of the column; a filler 106 is wrapped inside the abutting column, and the top of the abutting column and the The top seat 101 is connected; the front part of the...

Embodiment 2

[0040] The braided mesh valve repair clip of this embodiment differs from Embodiment 1 in that:

[0041] In this example, the auxiliary clipping bracket is omitted, and the braided mesh clip material uses materials with sufficient elasticity and yield strength to simplify the structure and reduce the overall weight.

[0042] For other structures, refer to Embodiment 1.

Embodiment 3

[0044] The braided mesh valve repair clip of this embodiment differs from Embodiment 1 in that:

[0045] In this example, the end of the guide wire of the control wire adopts a circular ring shape. After the valve clip captures and clamps the valve, the local control wire is retained, and can be reused in the later stage for the recovery of the delivery device or the replacement of the repair fixture.

[0046] For other structures, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com