A device and method for separating aldehyde and catalyst in olefin hydroformylation to aldehyde

A technology of olefin hydroformyl and catalyst, which is applied in the field of separation, can solve problems such as increased equipment investment and operating costs, insufficient waste gas utilization, and incomplete separation of catalysts, and achieves the goals of reducing energy consumption, prolonging service life, and improving separation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

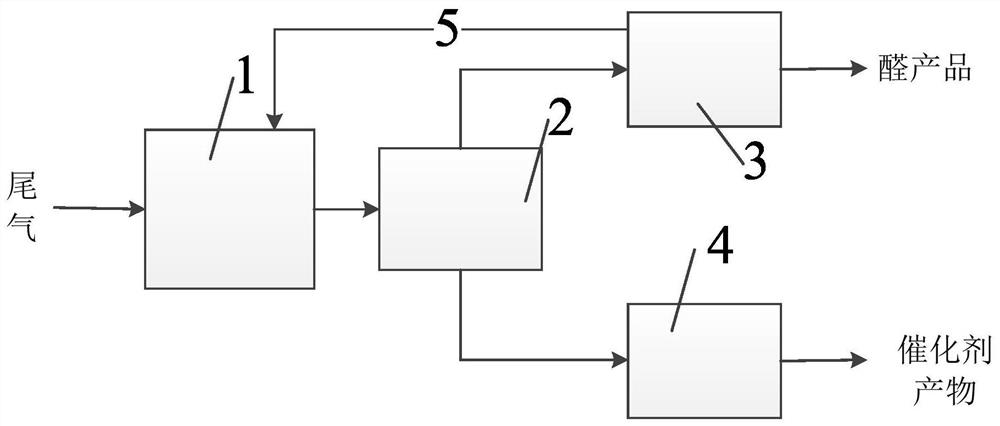

[0068] This embodiment provides a device for separating aldehydes and catalysts in the production of aldehydes by hydroformylation of olefins. like figure 1 shown; the outlet of the falling film evaporator 1 is connected to the inlet of the collection separator 2;

[0069] The liquid outlet of the collection separator 2 is connected with the feed port of the pressurized impurity removal device 4;

[0070] The air outlet of the collecting separator 2 is connected with the air inlet of the separating and pressurizing device 3;

[0071] The falling film evaporator 1 is provided with a tail gas inlet for aldehyde production by hydroformylation of olefins.

[0072] The falling film evaporator 1 is provided with a liquid phase material inlet;

[0073] Described liquid phase material import is the import of liquid phase product in olefin hydroformylation to make aldehyde;

[0074] The collection separator 2 is a gas-liquid separation tank;

[0075] The separation and pressurizat...

Embodiment 2

[0078] The present embodiment provides a device for separating aldehyde and catalyst in the production of aldehyde by hydroformylation of olefin, the separation device includes a falling film evaporator 1, a collection separator 2, a separation and pressurization device 3 and a pressurized decontamination device 4;

[0079] The outlet of the falling film evaporator 1 is connected to the inlet of the collection separator 2;

[0080] The liquid outlet of the collection separator 2 is connected with the feed port of the pressurized impurity removal device 4;

[0081] The air outlet of the collecting separator 2 is connected with the air inlet of the separating and pressurizing device 3;

[0082] The collection separator 2 is provided with an inlet of the tail gas for aldehyde production by hydroformylation of olefins.

[0083] The falling film evaporator 1 is provided with a liquid phase material inlet;

[0084]Described liquid phase material import is the import of liquid phas...

Embodiment 3

[0089] The present embodiment provides a device for separating aldehyde and catalyst in the production of aldehyde by hydroformylation of olefin, the separation device includes a falling film evaporator 1, a collection separator 2, a separation and pressurization device 3 and a pressurized decontamination device 4;

[0090] The outlet of the falling film evaporator 1 is connected to the inlet of the collection separator 2;

[0091] The liquid outlet of the collection separator 2 is connected with the feed port of the pressurized impurity removal device 4;

[0092] The air outlet of the collecting separator 2 is connected with the air inlet of the separating and pressurizing device 3;

[0093] The separation and pressurization 3 is provided with a tail gas inlet for aldehyde production by hydroformylation of olefins.

[0094] The falling film evaporator 1 is provided with a liquid phase material inlet;

[0095] Described liquid phase material import is the import of liquid ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com