A kind of biaxially stretched poly-4-methyl-1-pentene film and preparation method thereof

A technology of bidirectional stretching and longitudinal stretching, applied to flat products, other household appliances, household appliances, etc., can solve the problems of difficult film formation, easy breakage, and difficulty in controlling the uniformity of thickness, so as to solve the problems of easy breakage and increase plasticity and tensile properties, the effect of preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

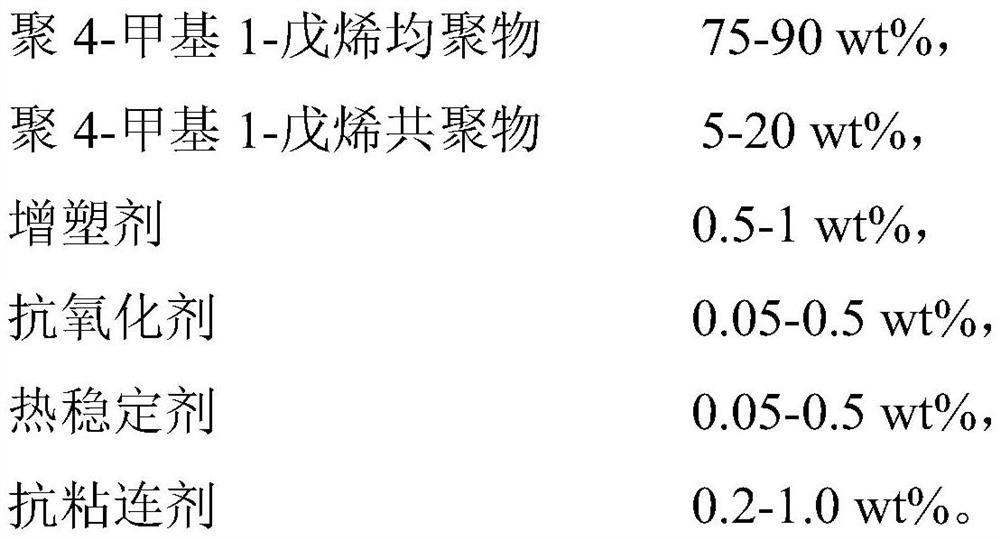

Method used

Image

Examples

Embodiment 1

[0026] An electrical grade poly-4-methyl-1-pentene resin with an ash content of less than 10ppm, a melt index of 18g / 10min, a crystallinity of 40% and an improved electrical grade was used in a nitrogen-isolated environment by a seven-stage heated main extrusion Machine extrusion, extrusion temperature 285 ℃, through metering pump, filter, melt pipeline, filter should use butterfly filter, melt is extruded into sheet shape through die head, die lip opening 0.9mm, die head temperature At 280°C, the melt adhered closely to the chill roll at a temperature of 90-100°C and was cooled and solidified. The back was cooled by a heated air knife. The gas temperature of the air knife was the same as that of the chill roll, and the gas pressure of the air knife was 110 mbar. In the longitudinal stretching area, the longitudinal preheating temperature is set at 130-150 °C, the longitudinal stretching temperature is kept at 140-150 °C, and the longitudinal direction is stretched by 3.5 times...

Embodiment 2

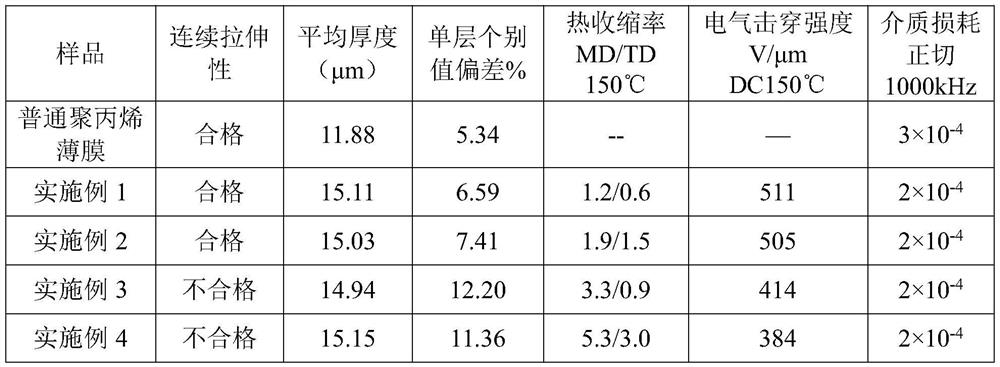

[0028] The preparation method is the same as in Example 1, except that the temperature of the transverse drawing heat setting is adjusted from 160° C. to 120° C., and other process parameters are the same as those of Example 1, to obtain a biaxially oriented polymethylpentene film of the same thickness, The obtained polymethylpentene film was tested for performance, and the performance parameters are shown in Table 1.

Embodiment 3

[0030] The preparation method is the same as in Example 1, except that the longitudinal and transverse stretch ratios are adjusted from 3.5 and 5.0 to 2.85 and 6.15, respectively, to obtain a biaxially stretched poly-4-methyl-1-pentene film of the same thickness, which will be prepared. The performance of the polymethylpentene film was tested, and the performance parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com