Method for fabricating organic thin film transistor in plastic base plate

A technology of organic thin film and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., and can solve problems affecting the electrical properties of organic thin-film transistors, high material costs, and the inability to improve the arrangement efficiency of organic semiconductor materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

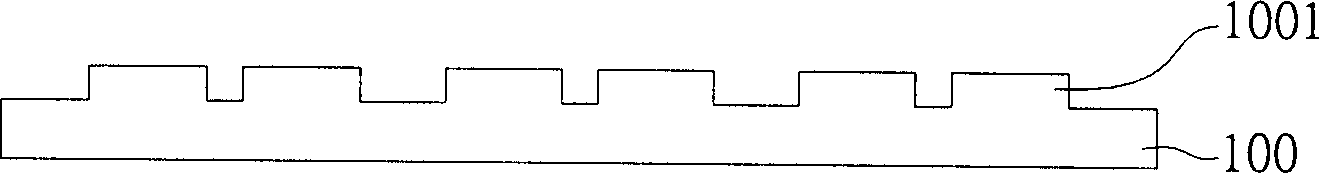

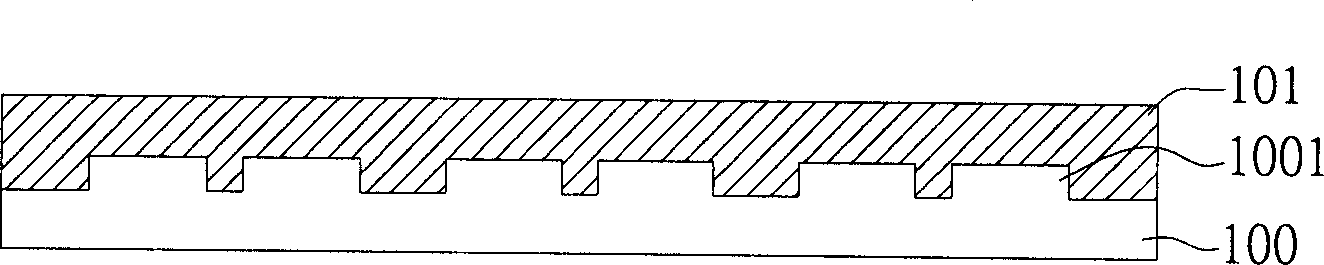

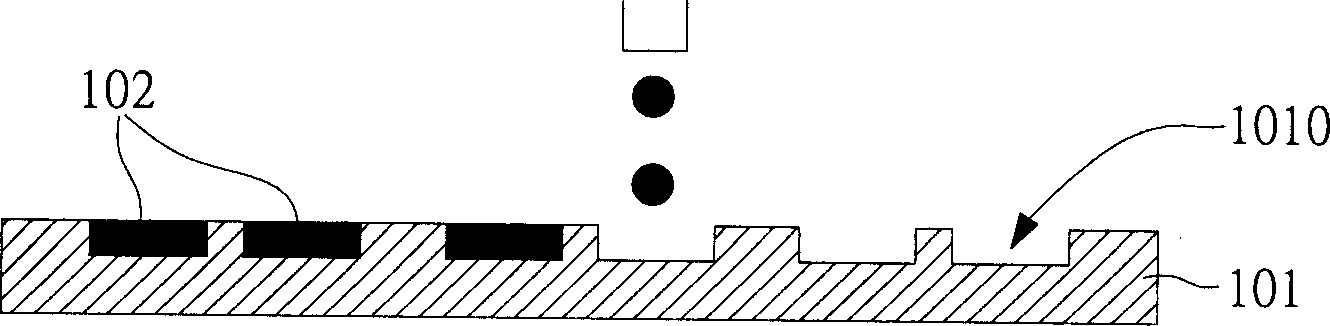

[0046] Figure 1A to Figure 1G This is the first embodiment of the method for manufacturing an organic thin film transistor on a plastic substrate of the present invention

[0047] The embodiment shows a flowchart.

[0048] Such as Figure 1A As shown, a master mold 100 is provided, wherein the master mold 100 has a relief structure 1001, and the relief structure 1001 can be made with German deep molding (LIGA) technology, because the deep molding (LIGA) technology is suitable for mass production of high aspect ratio ( Aspect Ratio) and low surface roughness (Sub μm) straight sidewall microstructure, and deep molding (LIGA) technology is to paste a layer of dry film or coating a layer of polymer material on the master mold 100 (Figure Not shown), where the thickness of the dry film or polymer material depends on the thickness of the workpiece or the depth of the microstructure, ranging from a few 10 μm to a few 100 μm. Generally, laser processing is used. The light source project...

no. 2 Embodiment

[0054] Figure 2A to Figure 2G It is the second embodiment of the manufacturing method of the organic thin film transistor on the plastic substrate of the present invention

[0055] The embodiment shows a flowchart.

[0056] in Figure 2A In this case, a master mold 200 is provided, wherein the master mold 200 has a relief structure 2001, and the relief structure 2001 can be made with German deep molding (LIGA) technology.

[0057] Such as Figure 2B As shown, the plastic substrate 201 is extruded by the master mold 200, and the relief structure 2001 can define the gate position of the plastic substrate 201 at this time. The plastic substrate 201 can be used with a side chain end group as -CH 3 Or -NH 2 The polymer materials used as substrate materials, such as: polymethyl methacrylate or cyclic olefin copolymer and other plastic materials. When the plastic substrate 201 is made by extrusion molding, the yellow light and etching processes can be omitted at the same time, so as to...

no. 3 Embodiment

[0062] Figure 3A to Figure 3G This is the third embodiment of the method for manufacturing an organic thin film transistor on a plastic substrate of the present invention

[0063] The embodiment shows a flowchart.

[0064] in Figure 3A In this case, a master mold 300 is provided, wherein the master mold 300 has a relief structure 3001, and the relief structure 3001 can be made by German deep molding (LIGA) technology.

[0065] Such as Figure 3B As shown, the master mold 300 is used to extrude the plastic substrate 301, and at this time, the relief structure 3001 can define the gate position of the plastic substrate 301. The plastic substrate 301 can be used with a side chain end group as -CH 3 Or -NH 2 The polymer material is used as the substrate material, such as: polymethyl methacrylate or cyclic olefin copolymer and other plastic materials. When the plastic substrate 301 is made by extrusion molding, the yellow light and etching processes can be omitted at the same time, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com