Environment-friendly normal-temperature thermosetting modified adhesive material for rapid repair

An adhesive material and environmentally friendly technology, applied in the field of environmental protection and energy saving, can solve the problems of long maintenance time, poor weather resistance and water stability, and use, and achieve the effect of short closed traffic time, durable use performance, and excellent use performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] 1. The preparation of environment-friendly normal temperature thermosetting modified asphalt, which consists of the following steps:

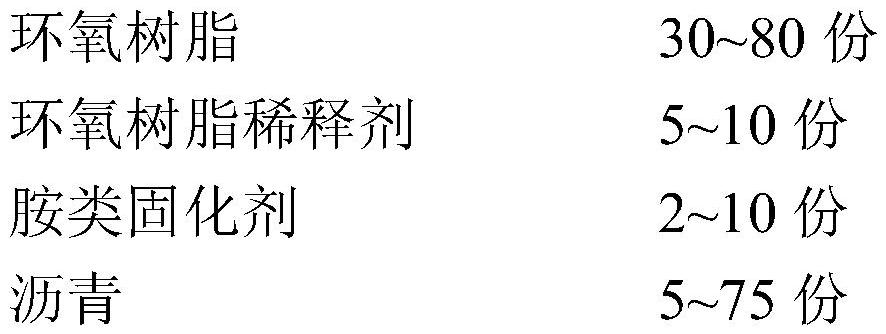

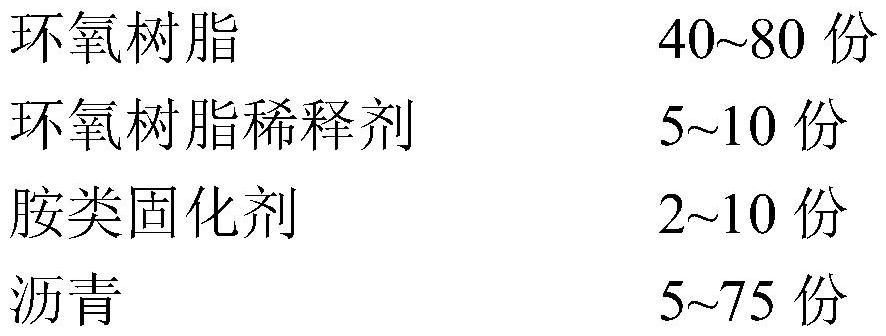

[0029] Step 1: Take 40-80 parts by mass of epoxy resin, 5-10 parts by mass of epoxy resin diluent, 2-10 parts by mass of amine curing agent and 45%-95% of 5-75 parts by mass of pitch In the reactor, heat up to 50-95°C, react for 1-2 hours, then add the remaining asphalt, stir for 30-60 minutes, and obtain component C;

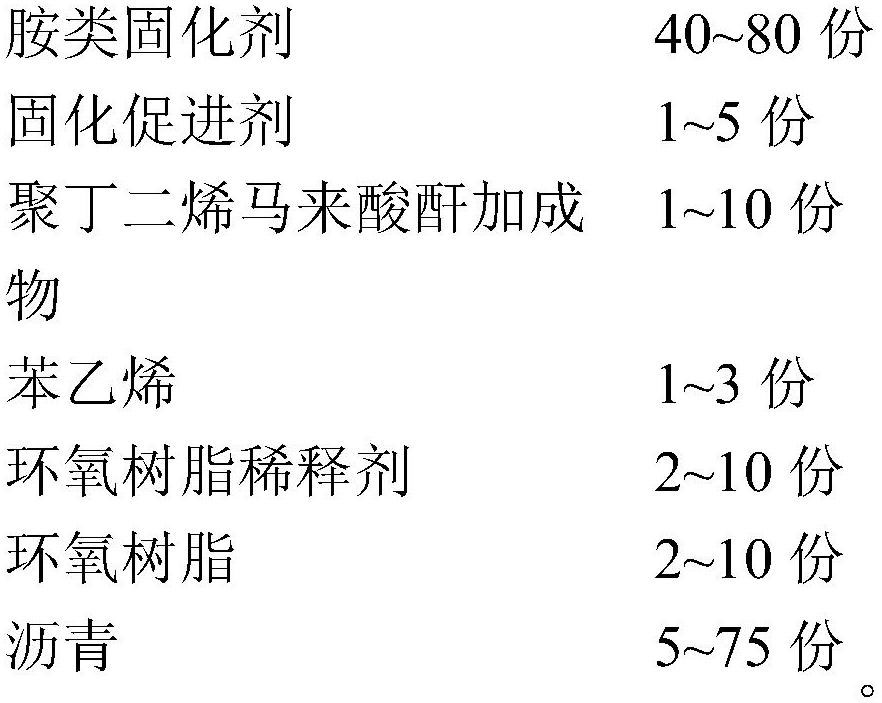

[0030] Step 2: Take 40-80 parts by mass of amine curing agent, 1-5 parts by mass of curing accelerator, and 2-10 parts by mass of epoxy resin into the reaction kettle, heat up to 55-95°C, react for 30-60 minutes, and then Add 1 to 10 parts by mass of polybutadiene maleic anhydride adduct, 1 to 3 parts by mass of styrene, 2 to 10 parts by mass of epoxy reactive diluent, and 5 to 75 parts by mass of asphalt into the reactor, and heat up to 60-85°C, mix and stir for 30-60 minutes, and react the above materials for 1-6 hours...

Embodiment 1

[0038] 1. Preparation of environment-friendly thermosetting modified asphalt at room temperature: take 60 parts by mass of epoxy resin (U.S. Huntsman MY790-1) in component C, epoxy resin diluent (Dehong New Material Co., Ltd. epoxy diluent UR -8748) 9 parts by mass, 5 parts by mass of amine curing agent (U.S. Huntsman D-400), 20 parts by mass of Shell 70# common asphalt. Add them together into the reactor, raise the temperature to 60°C, react for 2 hours, then add the remaining 25 parts by mass of asphalt, and mix and stir for 35 minutes to obtain component C;

[0039] Take the amine curing agent in the D component (U.S. Huntsman 3229) 56 parts by mass, amine curing agent (U.S. Huntsman ARADUR-350) 8 parts by mass, curing accelerator (Hunsman Accelerator 960-1) 4 parts by mass, polybutadiene maleic anhydride adduct ( Evonik Degussa MA-75) 4 parts by mass, styrene (TSI (Shanghai) Chemical Industry Development Co., Ltd.) 1 part by mass, epoxy resin (U.S. Huntsman MY 790-1) 5...

Embodiment 2

[0042]1. Preparation of environment-friendly thermosetting modified asphalt at room temperature: take 65 parts by mass of epoxy resin (Hunsman PY 306 from the United States) in component C, epoxy resin diluent (Hunsman epoxy diluent DY-F from the United States) 9 parts by mass, amine curing agent (U.S. Huntsman 3225) 4 parts by mass, Shell 90# ordinary asphalt 10 parts by mass. Add them together into the reactor, raise the temperature to 70°C, react for 1 hour, then add the remaining 10 parts by mass of asphalt, and mix and stir for 40 minutes to obtain component C;

[0043] Take the amine curing agent in the D component (U.S. Huntsman 3440) 75 parts by mass, curing accelerator (Hunsman Accelerator 960-1) 3 parts by mass, polybutadiene maleic anhydride adduct (Evonik Degussa MA-75) 5 parts by mass, styrene (TSI (Shanghai) Chemical Industry Development Co., Ltd.) 1 part by mass, epoxy resin (U.S. Huntsman GY 257) 8 parts by mass, epoxy reactive diluent (Henry, USA) Add 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com