A ground pulse cutting method for hard roof in mining working face

A technology of back mining and hard roof in the empty roadway, which is applied in the direction of ground mining, tunnels, mining equipment, etc., can solve the problems of easy deviation of test orientation, increase hidden dangers of coal mine safety production work, and inaccurate test data, etc., to achieve repetitive operations The effect of controllable times, convenient roof cutting operation and controllable working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings:

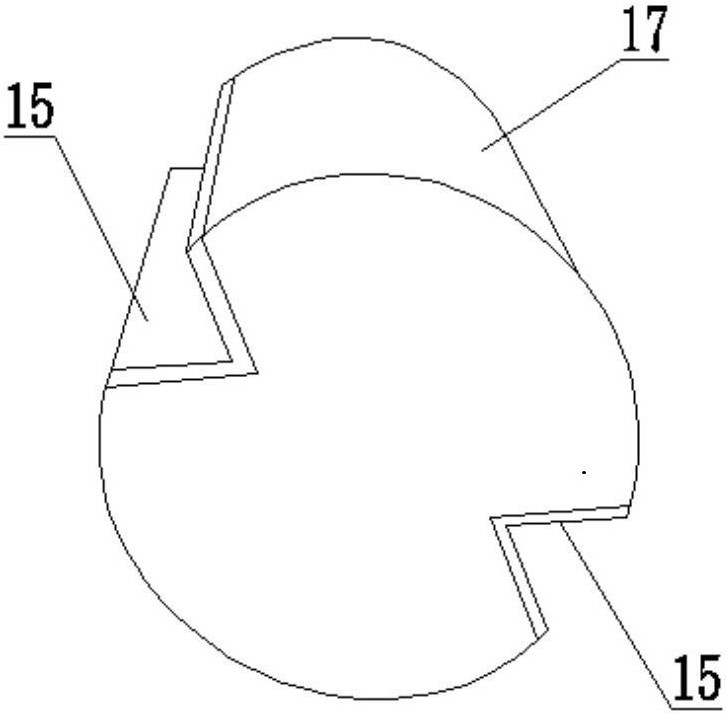

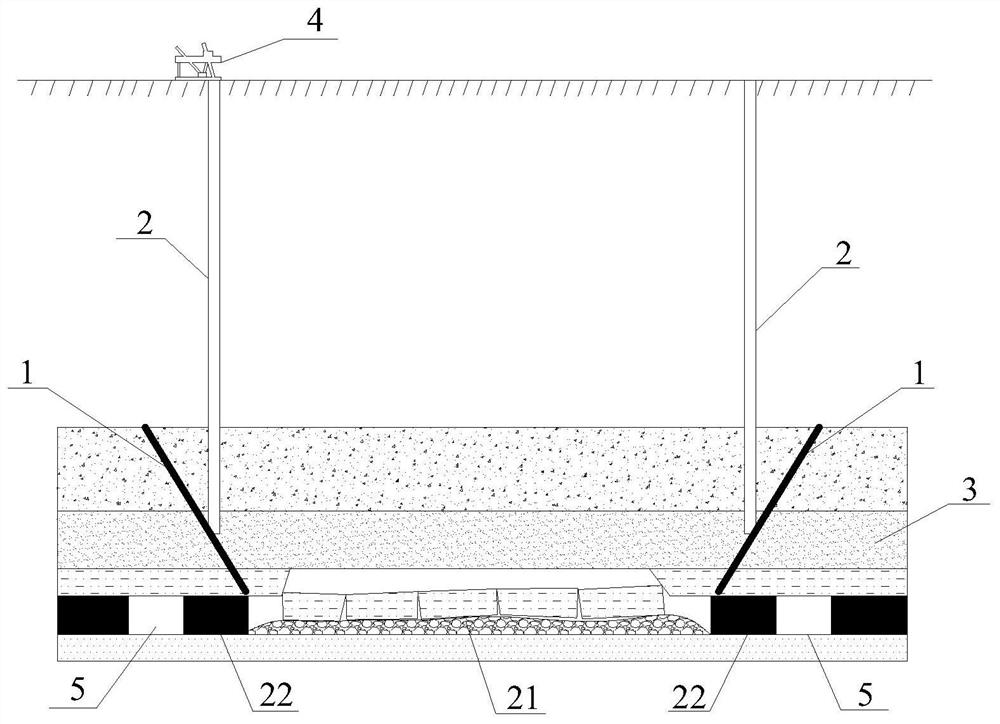

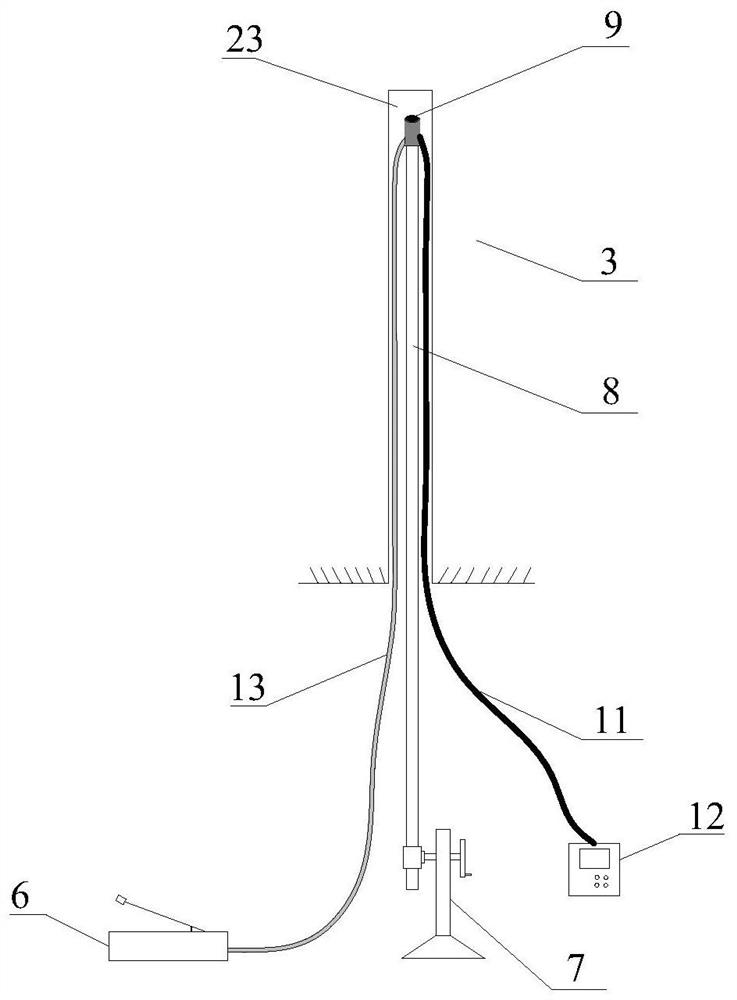

[0028] like Figure 1 to 9 As shown, a convolved road pulse cutting method of the present invention, including a drilling touch device and an electrical pulse device 4, the drilling device including a conveying rod 8, an elevator 7, The probe 9, the probe 10, the hand press pump 6 and the data acquisition device 12, the transport rod 8 is a telescopic rod member, and the lower end of the conveying rod 8 is connected to the lifter 7, and the outer diameter is less than the drilling 23 to be detected. Inner diameter; the lift 7 is fixedly mounted within the empty roadway 5, the elevator 7 is a can be lifted, and the pitch angle can be adjusted, but can also adjust the depth of the conveying rod 8 into the drilling 23, or adjust the conveying rod. 8 of the angle to accommodate different angles of drilling 23; the probe 9 is mounted on the upper end of the transport rod 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com