Fluid system component mechanical property detection device, detection system and detection method

A technology of fluid system and detection device, which is applied in the field of mechanical performance detection of fluid system components, and can solve problems affecting the exposure and positioning process of lithography machines and the exposure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

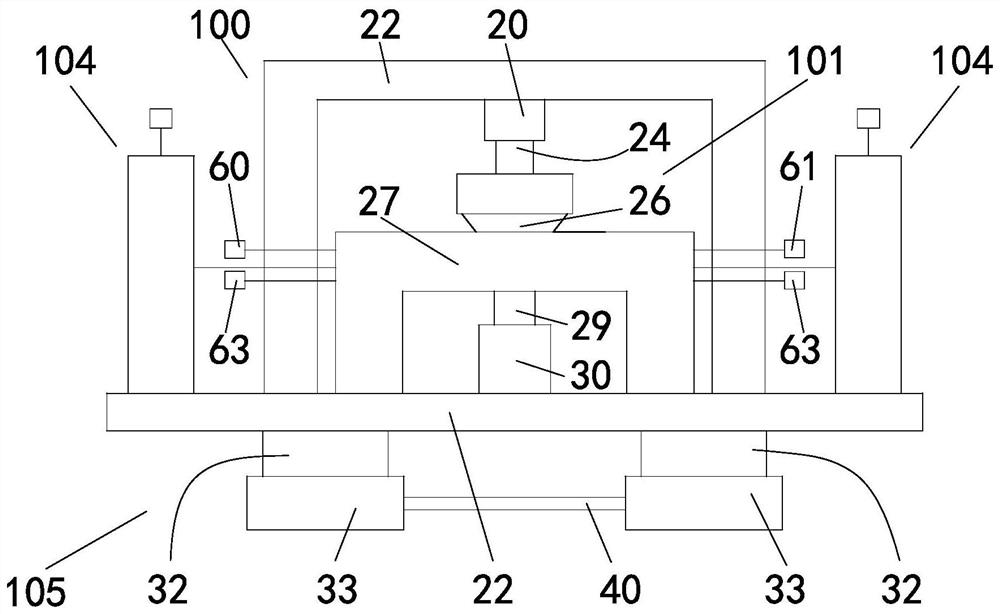

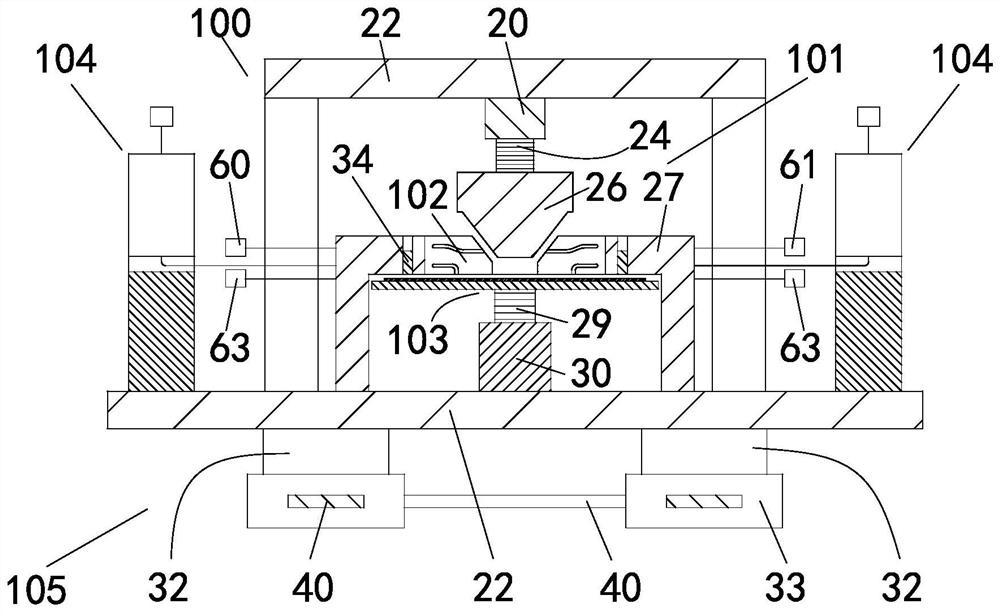

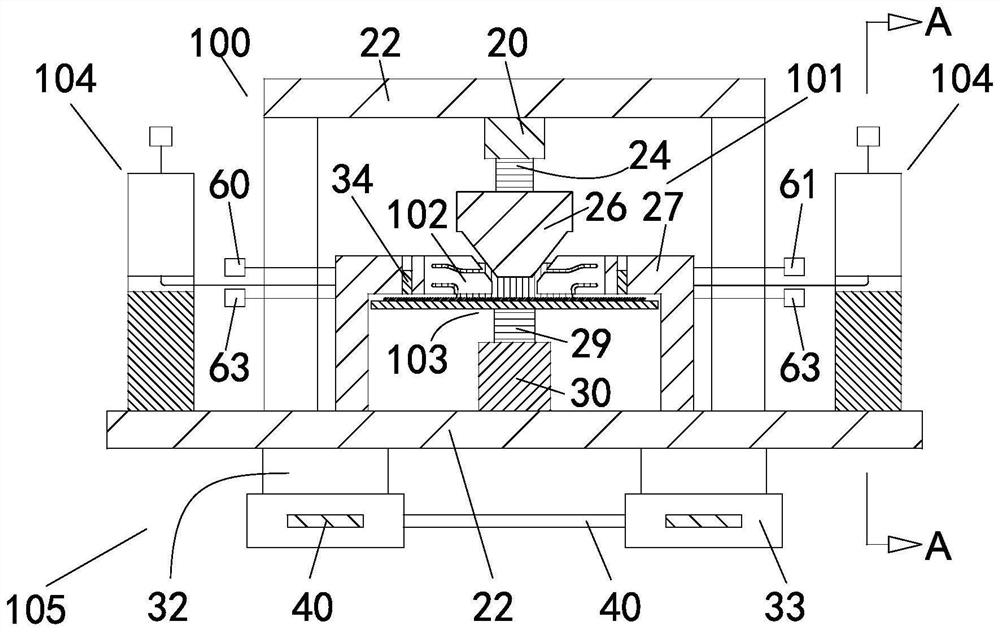

[0041] Figure 1-6 In the shown embodiment, a device for testing the mechanical properties of fluid system components includes a test bench frame 22, a first three-axis adjuster 20 is installed on the underside of the top of the test stand frame 22, and the first three-axis adjuster 20 Its lower end is fixedly connected with an uplink disturbance detection mechanism 101. The first three-axis adjuster 20 adjusts the plane orientation of the plane where the uplink disturbance detection mechanism 101 is located by adjusting the plane orientation of its own plane. Below the uplink disturbance detection mechanism 101 is a The main body mechanism 102 of the immersion unit and the downlink disturbance detection mechanism 103, the centers of the uplink disturbance detection mechanism 101, the main body mechanism 102 of the immersion unit and the downlink disturbance detection mechanism 103 are all located on the same center vertical connecting line, and the uplink disturbance detection...

Embodiment 2

[0050] Figure 1-6 In the shown embodiment, a fluid system component mechanical property testing system includes a data acquisition card 50, a data processing terminal 51 and the fluid system component mechanical property testing device 100 described in Embodiment 1, and the fluid system component mechanical property The various sensors set in the performance detection device 100 are connected to the data acquisition card 50 through external cables, and the signals collected by the sensors are transmitted to the data processing terminal 51 via the data acquisition card 50 through the external cables, and the others are the same as in Embodiment 1. same.

Embodiment 3

[0052] Figure 1-6 In the shown embodiment, a method for testing the mechanical properties of fluid system components includes the following testing steps:

[0053] A1. Debugging preparation steps before testing;

[0054] Through the first three-axis adjuster 20 and the second three-axis adjuster 30 described in Embodiment 1 or Embodiment 2, the upward disturbance detection mechanism 101 and the downward disturbance detection mechanism 103 are adjusted to be in the same vertical center as the main body mechanism 102 of the immersion unit. position on the straight line;

[0055] A2. Fluid system simulation formation steps before testing;

[0056] Through the fluid system component mechanical performance detection device 100 described in embodiment 1 or embodiment 2, by adjusting the liquid supply module 60, the liquid discharge module 61, the gas supply module 63 and the gas discharge module 62, the fluid with a steady state is simulated system;

[0057] A3. Carry out the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com