Method of determining OPC minimum segmentation length

A minimum and wide technology, applied in the photoplate making process of the pattern surface, the original for photomechanical processing, the microlithography exposure equipment, etc., can solve the problem of low OPC correction accuracy, and the target layout pattern cannot be reasonably segmented, etc. problems, to achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention provides a method for determining the OPC minimum segment length, such as Figure 7 as shown, Figure 7 Shown is the flow chart of the method for determining the OPC minimum segment length of the present invention. The method at least includes the following steps:

[0041] Step 1. Determine the target layer and the ADI target value corresponding to the target layer (CD of the photoresist pattern after development) as ADItarget; further in the present invention, the ADI target value in step 1 of this embodiment is the graphic line width (The line width of the photoresist pattern after development). Still further in the present invention, the ADI target value ADI target in step 1 of this embodiment is 81nm.

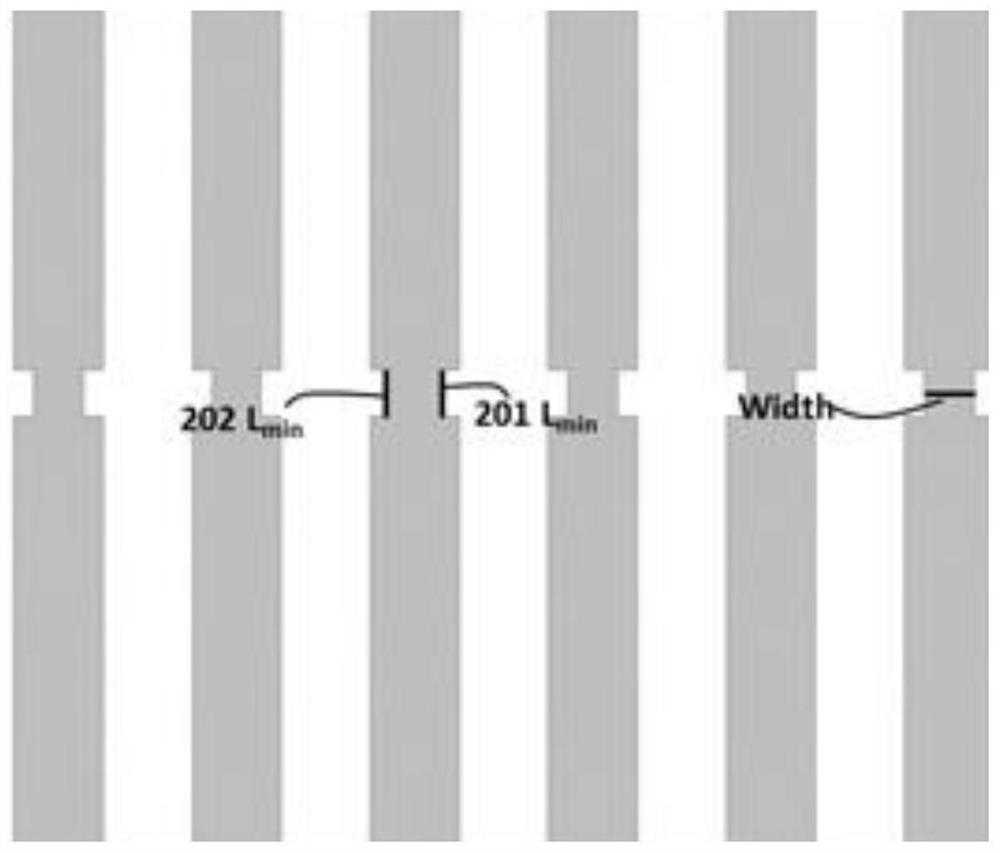

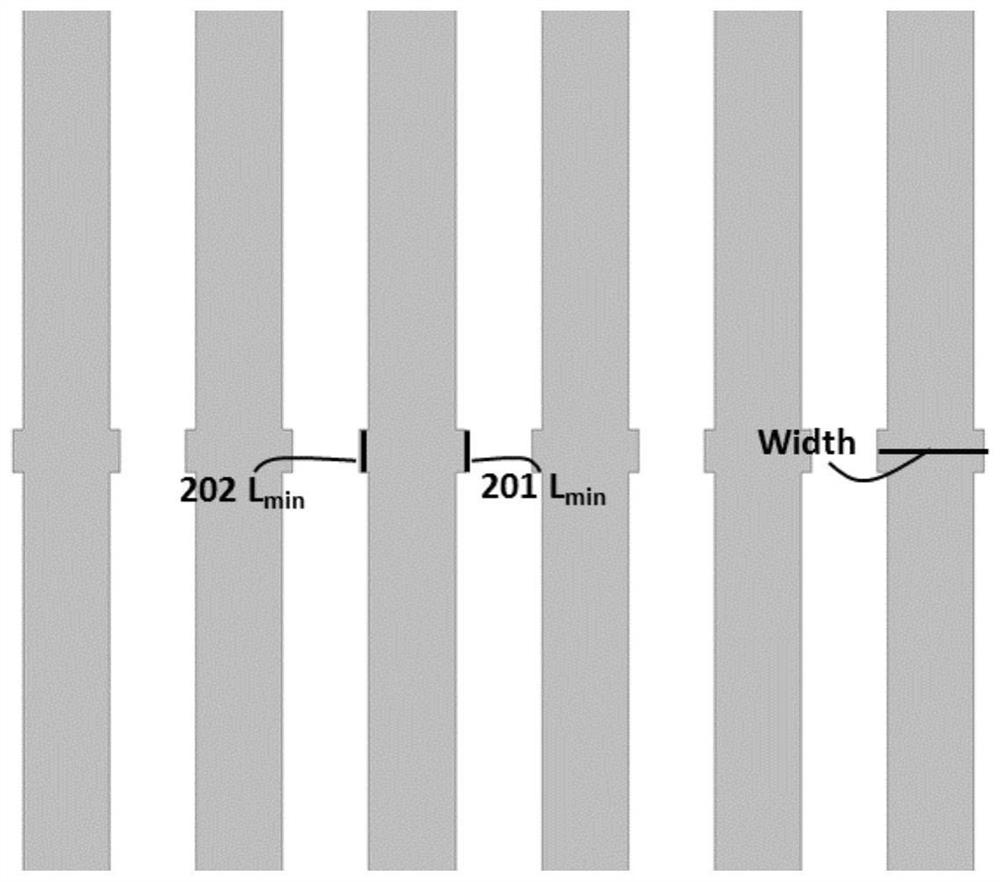

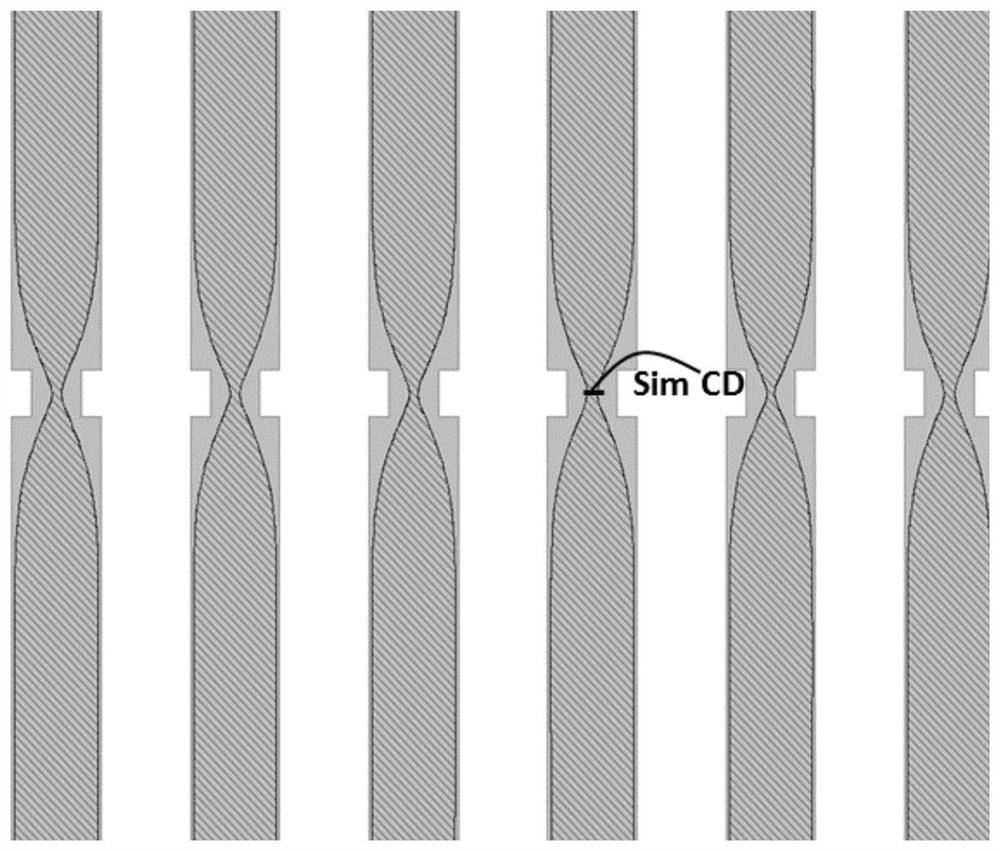

[0042] Step 2, obtain the value range and the value range of the length segment value and the width or spacing segment value based on the OPC-processed test pattern according to the ADI target value; within the value range of the length segme...

Embodiment 2

[0050] The present invention provides a method for determining the OPC minimum segment length, such as Figure 7 as shown, Figure 7 Shown is the flow chart of the method for determining the OPC minimum segment length of the present invention. The method at least includes the following steps:

[0051] Step 1. Determine the target layer and the ADI target value corresponding to the target layer (CD of the photoresist pattern after development) as ADItarget; further in the present invention, the ADI target value in step 1 of this embodiment is the pattern pitch ( The distance between two adjacent photoresist patterns after development) Further in the present invention, the ADI target value ADItarget in step 1 of this embodiment is 81 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com