Cleaning equipment for mechanical parts

A technology for mechanical parts and cleaning equipment, which is applied in the field of mechanical parts cleaning, can solve the problems of reduced cleaning efficiency, waste of water resources, and time-consuming problems, so as to avoid blockage of water holes, improve cleaning efficiency, and improve cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

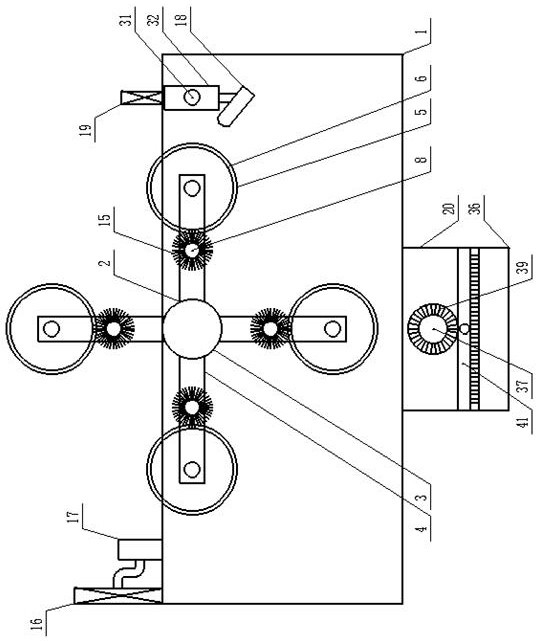

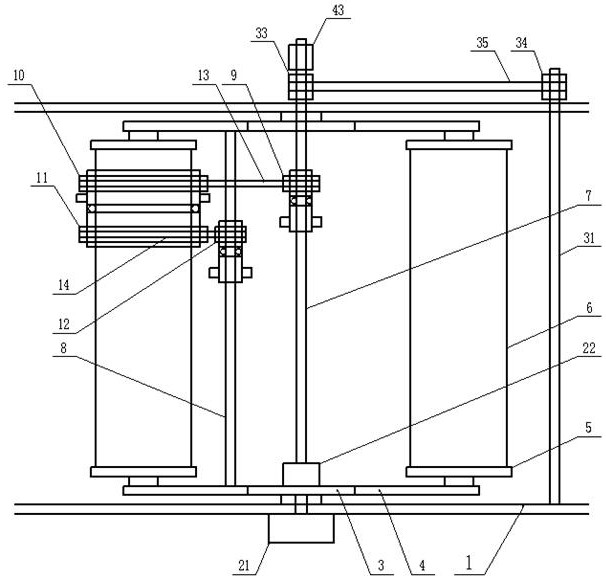

[0015] Example 1: see figure 1 , figure 2 , image 3 , Figure 4Now, a kind of cleaning equipment for mechanical parts provided by the present invention is described, which includes a cleaning body 1 designed with an upper end opening, and a cleaning mechanism 2 is provided in the cleaning body 1, and the cleaning mechanism 2 includes the length The top of the inner end wall on both sides of the direction is movably provided with a disc-shaped turret 3, a disc-shaped turret 3, and an equal arc on the outer circumferential end wall. Fixedly be provided with disc-shaped mounting frame 5, the cylindrical cleaning frame 6 that is all fixedly provided with between the disc-shaped mounting frame 5 along described cleaning body 1 length direction, the first that is provided with between the disc-shaped turret 3 The transmission shaft 7 and the support frame 4 are provided with the second transmission shaft 8 along the length direction of the cleaning body 1, the first driving pul...

Embodiment 2

[0016] Example 2: see figure 1 , figure 2 , image 3 , a kind of cleaning equipment for mechanical parts provided by the present invention is now described, the top of the outer end wall on one side of the length direction of the cleaning body 1 is provided with a first motor 21, and the output shaft of the first motor 21 extends into the cleaning In the body 1, and its protruding end end is fixedly connected with the central portion of the disc-shaped turret 3, and the number of support frames 4 provided on the outer peripheral end wall of the disc-shaped mounting frame 5 is four, so The support frame 4 is arranged along the radial direction of the cross section of the disc-shaped mounting frame 5, and the disc-shaped turret 3 arranged near the position of the first motor 21 corresponds to the middle part of the end wall on the other side of the position of the first motor 21. A second motor 22 is provided, one end of the first transmission shaft 7 in the length direction ...

Embodiment 3

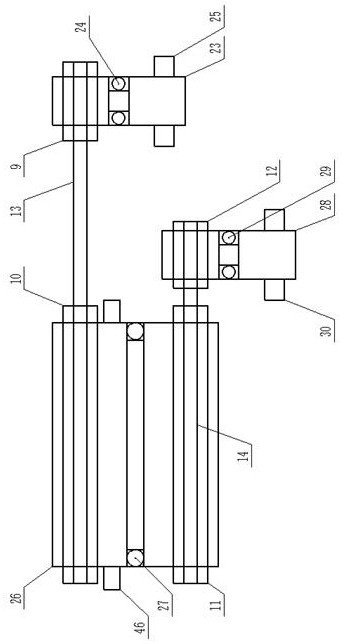

[0017] Embodiment 3: see figure 2 , image 3 , a kind of cleaning equipment for mechanical parts provided by the present invention is now described, the outside of the cylindrical cleaning frame 6 is sleeved on the second cylindrical transmission frame 26, and the inner diameter of the second cylindrical transmission frame 26 is larger than the The diameter of the outer end of the cross-section of the cylindrical cleaning frame 6, the second cylindrical drive frame 26 is provided with a second bearing-shaped connector between the inner end wall of the middle side in the length direction and the outer end wall of the cylindrical cleaning frame 6 27. The outer sides of the second cylindrical transmission frame 26 in the length direction are respectively covered with the first driven pulley 10 and the second driving pulley 11, and the outer end of one side of the second cylindrical transmission frame 26 is The second connecting cylinder 46 is evenly arranged on the wall with eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com