Laser cutting machine with automatic positioning function

A laser cutting machine and automatic positioning technology, applied in laser welding equipment, welding/cutting auxiliary equipment, manufacturing tools, etc., can solve the problems of difficult cutting of processed materials, decreased cutting accuracy, horizontal position deviation, etc., so as to avoid the reduction of cutting accuracy , Prevent the phenomenon of breaking and cutting, and prevent the effect of light and heavy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Such as Figure 1-Figure 5 Shown:

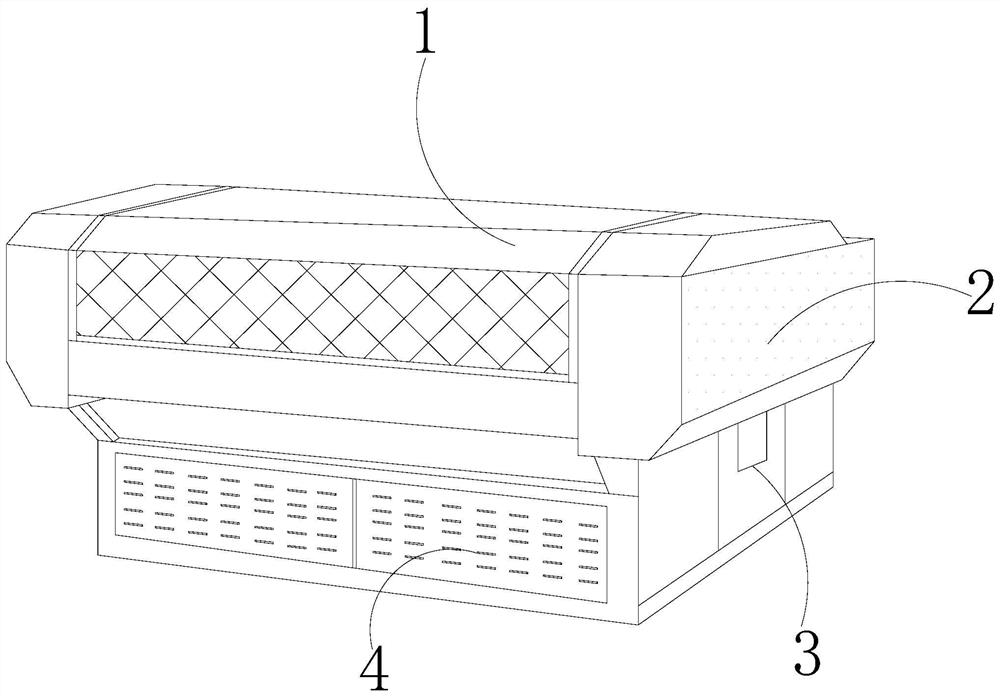

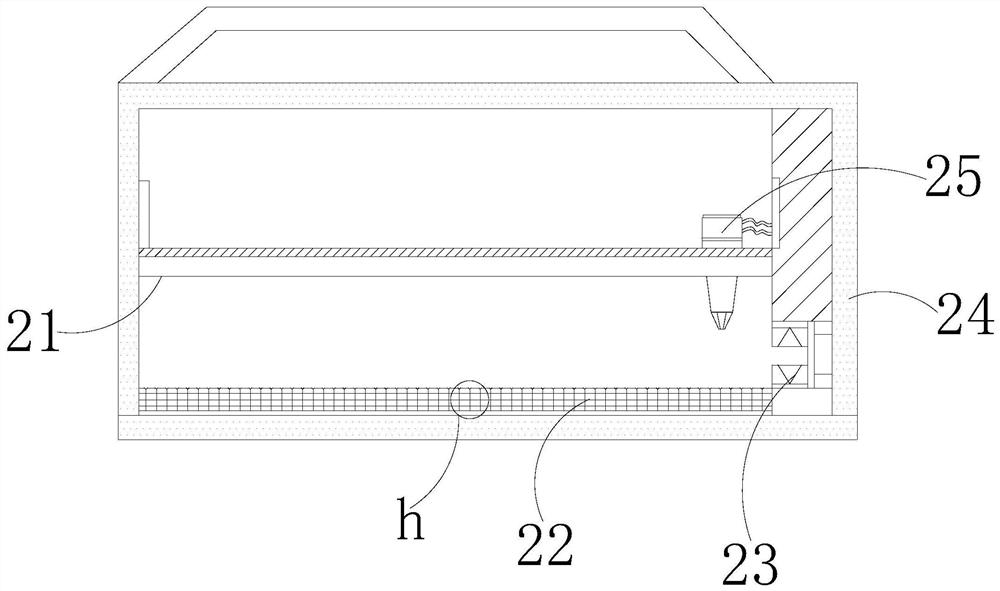

[0024] The present invention is a laser cutting machine with automatic positioning function. Its structure includes a sealing cover 1, a cutting device 2, a scrap outlet 3, and an air supply port 4. The sealing cover 1 is embedded in the upper end of the cutting device 2, and the air supply port 4 is located at the lower end of the cutting device 2, the scrap outlet 3 is installed below the cutting device 2, and the cutting device 2 is provided with a moving frame 21, a fixed structure 22, a rotating mechanism 23, a retractor 24, and a laser cutter 25. The moving frame 21 is embedded on the side of the expander 24, the laser cutter 25 is installed inside the moving frame 21, the rotating mechanism 23 is embedded on the inner side of the expander 24, and the fixed structure 22 is embedded on the inside of the expander 24 At the bottom, the upper end of the telescoping device 24 is embedded and connected with the sealing cover 1, and t...

Embodiment 2

[0031] Such as Figure 6-Figure 7 Shown:

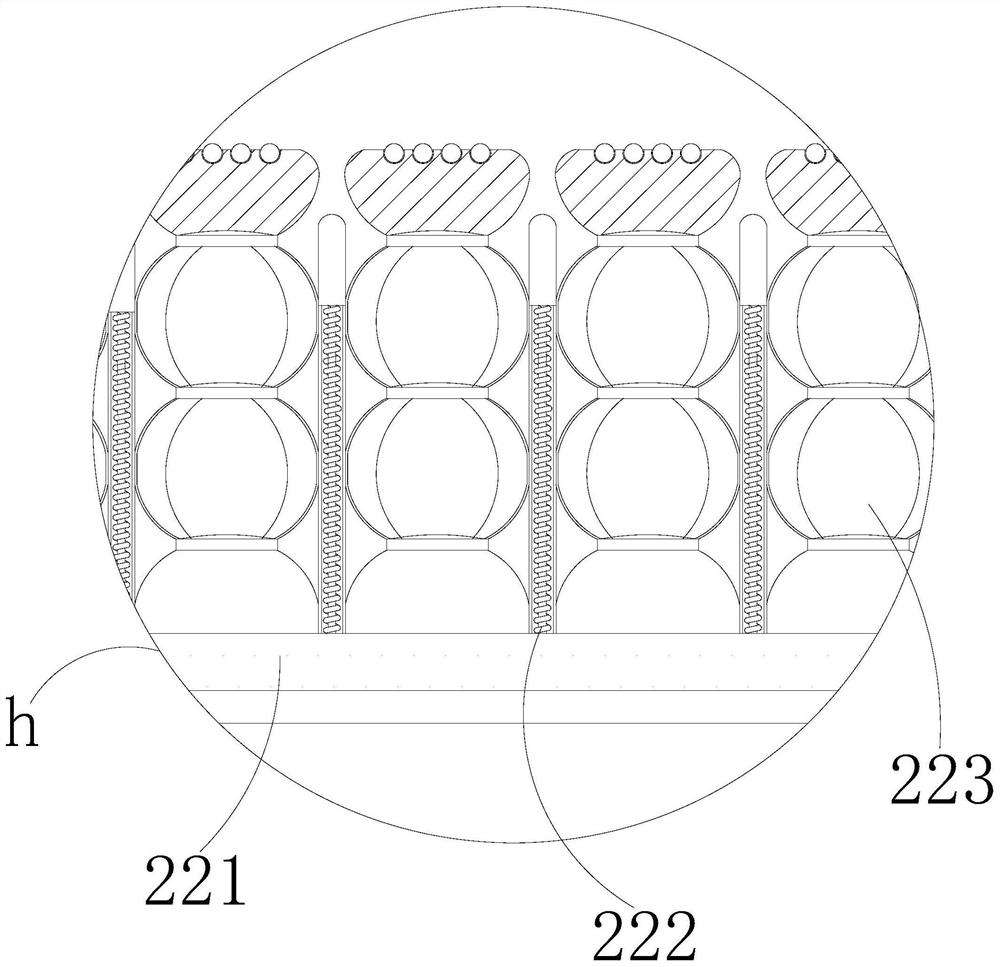

[0032]Wherein, the rotating mechanism 23 is provided with a rotating device 231, a connecting block 232, a rotating plate 233, and a moving rod 234. The rotating device 231 is embedded in the connecting block 232, and the connecting block 232 is installed on the side of the rotating plate 233. The rotating plate 233 is located at the left end of the moving rod 234, the rotating device 231 and the moving rod 234 are located on the same central axis, the moving rod 234 is embedded in the inner side of the retractor 24, and the connecting block 232 is narrow in the middle and wide on both sides. Cylindrical structure, the rotating plate 233 rotates around the moving rod 234, and the inner side of the rotating device 231 is parallel to the surface of the fixed structure 22, so that the processing material is fixed on the inner side of the rotating device 231, so that the processing material is fixed to the other side by rotating the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com