Single-head/double-head composite numerical control machine tool

A technology of composite CNC machine tools and machine heads, which is used in metal processing mechanical parts, large fixed members, maintenance and safety accessories, etc., can solve the problems of high procurement cost of high-precision CNC machine tools, effective travel restrictions in the size range, and inability to meet the needs of use. , to achieve the effect of saving equipment purchase cost and placement area, reducing purchase cost and increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

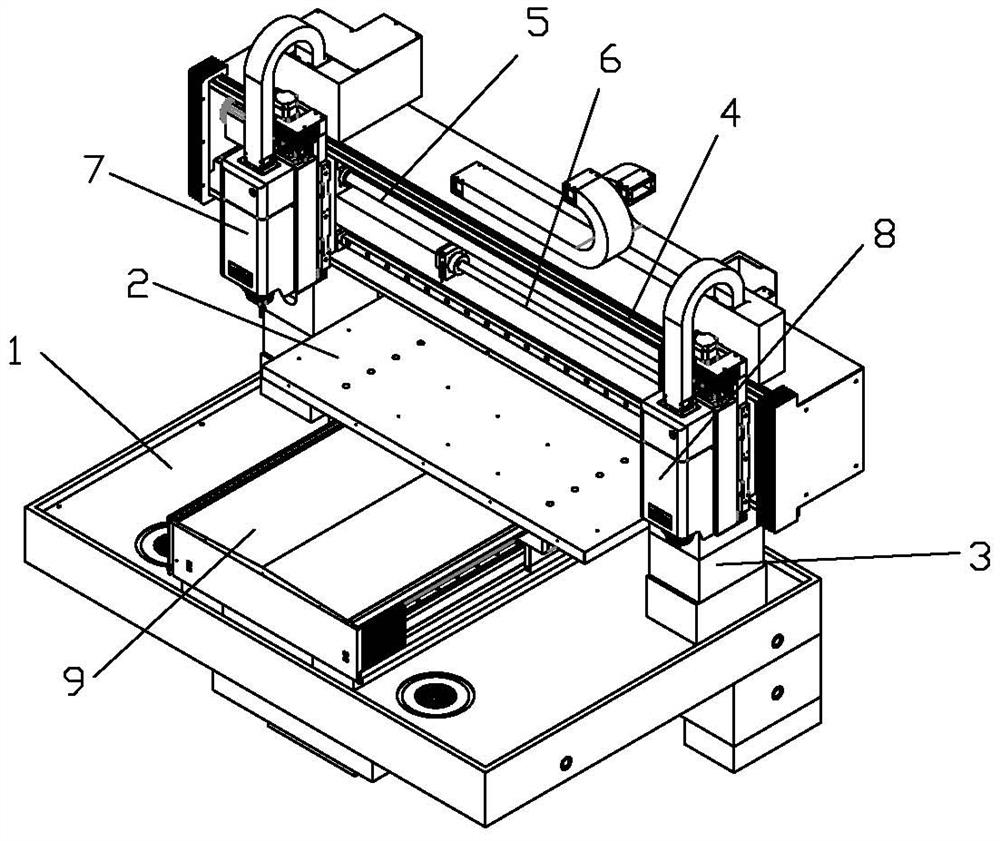

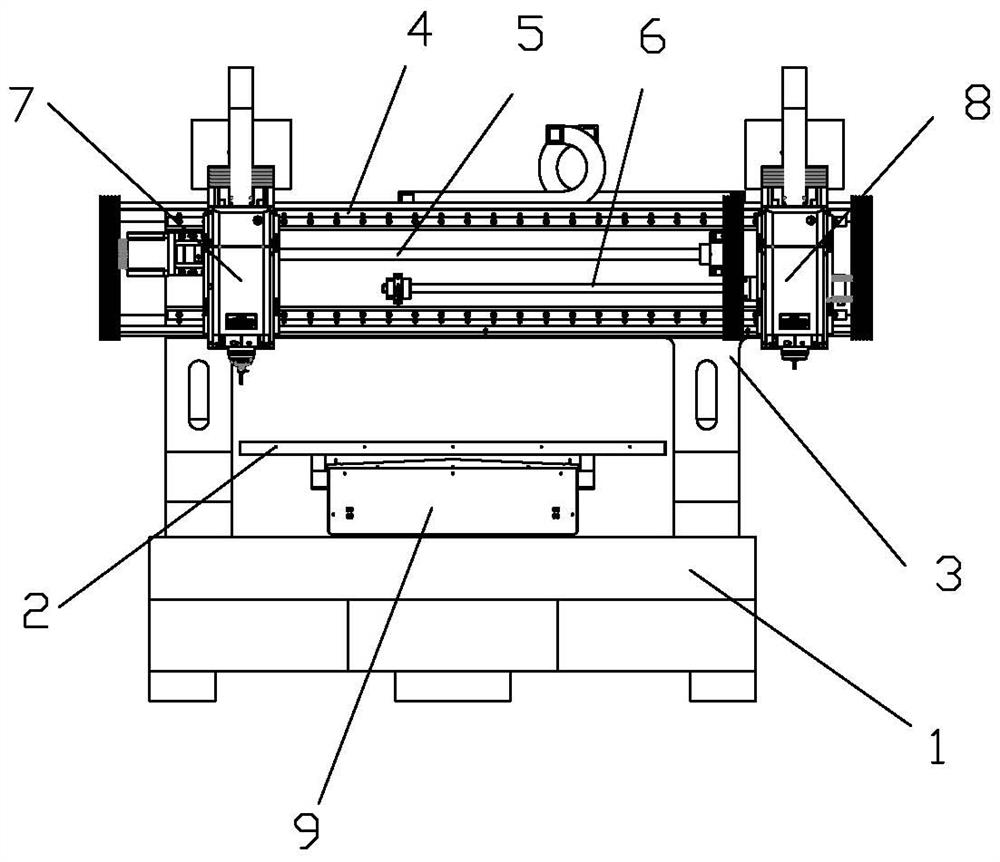

[0020] Please refer to the attached Figure 1-2 , a single-head / double-head compound numerical control machine tool, comprising a base 1, a workbench 2 movably arranged above the base 1, a gantry 3 arranged on the base 1, and the gantry 3 is located on the workbench 2 The upper part also includes the first slide rail 4 arranged on the gantry frame 3, the first screw mandrel 5 and the second screw mandrel 6 which are rotated, the first machine head 7 and the second screw mandrel 6 which are slidably arranged on the first slide rail 4 The second machine head 8 is used to drive the first XY-axis driving device for driving the first screw mandrel 5 to rotate, and the second XY-axis driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com