Method and device for treating ferrous fumarate wastewater

A technology of ferrous fumarate and treatment method, applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc. The process is short, the land occupation is small, and the processing process is very effective.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

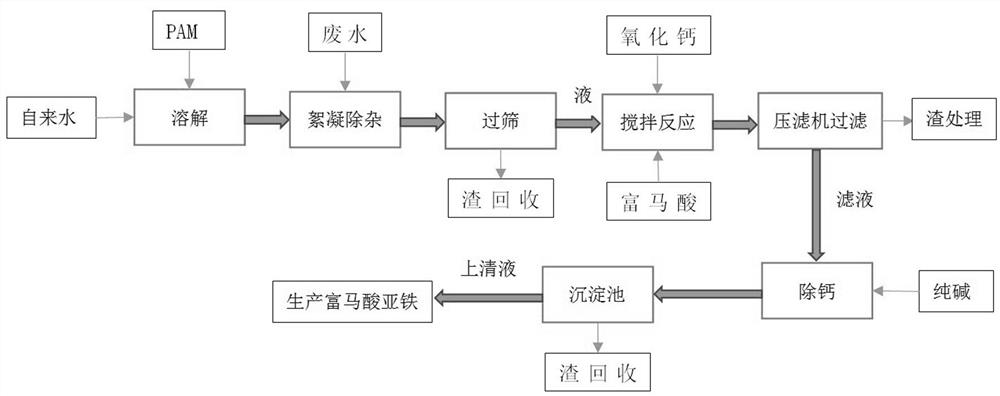

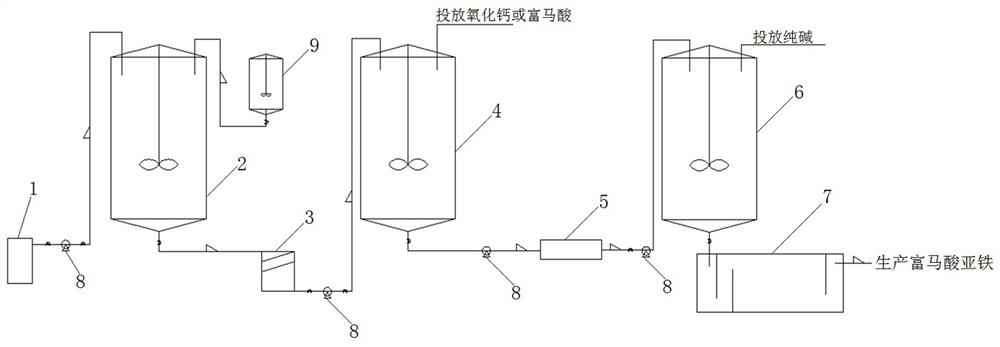

[0027] A treatment method for ferrous fumarate wastewater, comprising the following steps:

[0028] (1) Dissolving polyacrylamide (PAM): According to the weight ratio of polyacrylamide: water = 0.5:100, in the PAM mixing tank, add 0.4 kg of polyacrylamide to 80 kg of hot water at a temperature > 70 ° C, and stir Dissolve for more than 3 hours until completely dissolved to obtain a 5‰ PAM solution;

[0029] (2) Flocculation and impurity removal: pump 8000kg of ferrous fumarate wastewater (sulfate radical content X=12.06% in ferrous fumarate wastewater) from the stock solution pool into the mixing tank I, then add 5‰ PAM solution, When the solution appears tofu flower-like suspended matter, stop adding, stir for 5 minutes, then filter through a 60-mesh vibrating sieve, and recover the filter residue;

[0030] (3) Dosing of calcium oxide: Pump the sieved waste water into the mixing tank II, and add calcium oxide for 10 minutes, the dosage of calcium oxide is M 氧化钙 = M 废水 ×X×56...

Embodiment 2

[0036] A treatment method for ferrous fumarate wastewater, comprising the following steps:

[0037] (1) Dissolving polyacrylamide (PAM): According to the weight ratio of polyacrylamide: water = 0.5:100, in the PAM mixing tank, add 0.5 kg of polyacrylamide to 100 kg of hot water at a temperature > 70 ° C, and stir Dissolve for more than 3 hours until completely dissolved to obtain a 5‰ PAM solution;

[0038] (2) Flocculation and impurity removal: pump 10,000 kg of ferrous fumarate wastewater (sulfate radical content in ferrous fumarate wastewater X=12.0%) from the stock solution pool to the mixing tank I, and then add 5‰ PAM solution, When the bean curd flower-like suspended matter appears in the solution, stop adding, stir for 8 minutes, and then filter through a 60-mesh vibrating sieve to obtain the filter residue recovery;

[0039] (3) Dosing calcium oxide: Pump the sieved waste water into the mixing tank II, add calcium oxide, it takes 13 minutes, the dosage of calcium oxi...

Embodiment 3

[0045] A treatment method for ferrous fumarate wastewater, comprising the following steps:

[0046] (1) Dissolving polyacrylamide (PAM): According to the weight ratio of polyacrylamide: water = 0.5:100, in the PAM mixing tank, add 0.75 kg of polyacrylamide to 150 kg of hot water at a temperature > 70 ° C, and stir Dissolve for more than 3 hours until completely dissolved to obtain a 5‰ PAM solution;

[0047] (2) Flocculation and impurity removal: pump 15,000 kg of ferrous fumarate wastewater (sulfate radical content in ferrous fumarate wastewater X=11.96%) from the stock solution pool to the mixing tank I, and then add 5‰ PAM solution, When the solution appears tofu flower-like suspended matter, stop adding, stir for 10 minutes, then filter through a 60-mesh vibrating sieve, and recover the filter residue;

[0048] (3) Dosing calcium oxide: Pump the sieved waste water into the mixing tank II, and add calcium oxide for 15 minutes, the dosage of calcium oxide is M 氧化钙 = M 废水 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com