U-shaped coal gasification waste heat boiler with spray cooling device and cooling method

A waste heat boiler, spray cooling technology, applied in the field of boilers, can solve the problems of exhaust gas temperature caused by burning of the heating surface in the waste heat heat exchange chamber, slag is easy to adhere, and affects the safe operation of the gasifier, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

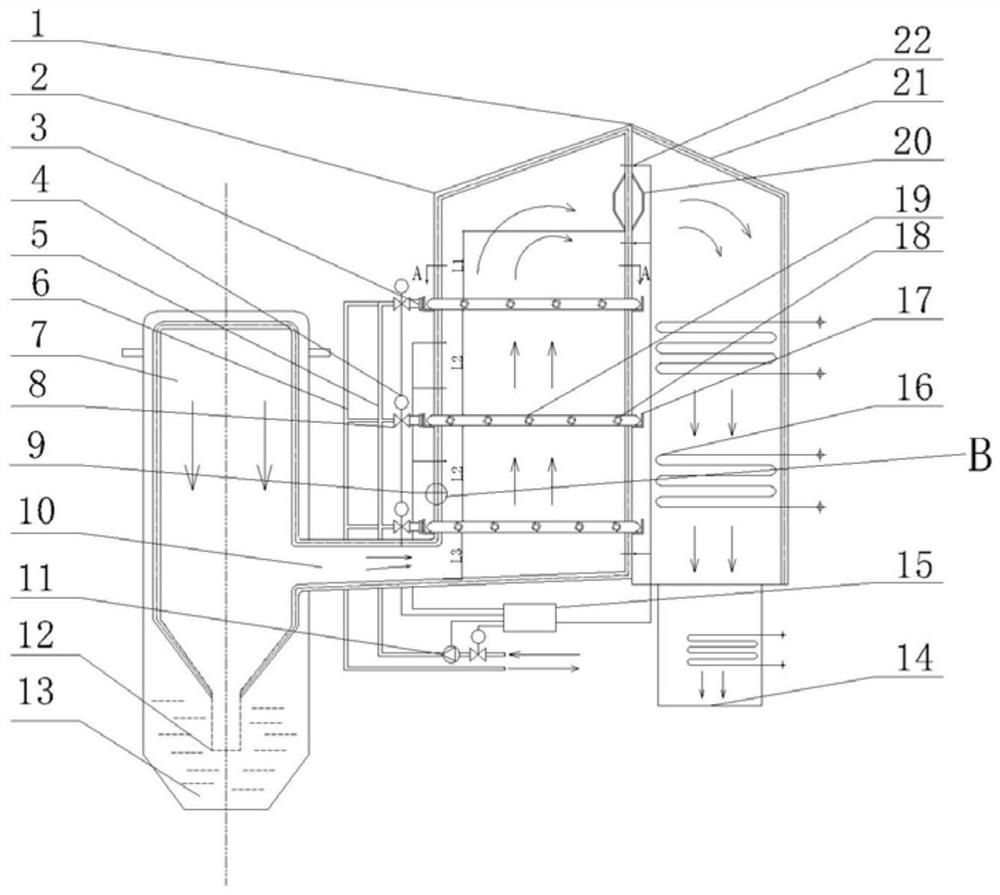

[0024] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, a U-shaped coal gasification waste heat boiler with a spray cooling device described in this embodiment, which includes a waste heat boiler body 1, a gasification furnace body 7, a horizontal flue 10, and a gasification furnace slag outlet 12 and slag pool 13; waste heat boiler body 1 includes secondary gasification chamber 2 and waste heat heat exchange chamber 21, characterized in that: secondary gasification chamber 2 includes spray system, water supply system and control system; gasification furnace body 7 It communicates with the secondary gasification chamber 2, the gasification furnace slag outlet 12 is set in the slag pool 13, the waste heat heat exchange chamber 21 is set close to the secondary gasification chamber 2, and the gasification furnace body 7 and the secondary gasification chamber 2 pass through The horizontal flue 10 is connected, and the waste heat heat exchange ...

specific Embodiment approach 2

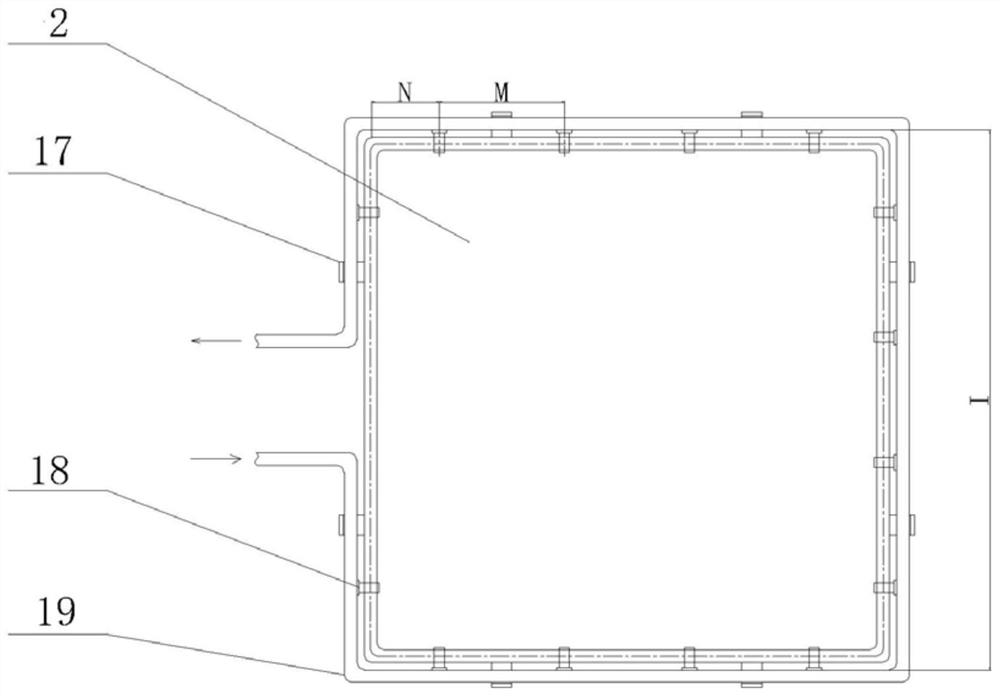

[0025] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, a U-shaped coal gasification waste heat boiler with a spray cooling device described in this embodiment, the spray system includes a plurality of connecting flanges 3, a plurality of brackets 17, a plurality of nozzles 18 and a plurality of spray Spray water pipe 19, the two ends of spray water pipe 19 are respectively equipped with a connecting flange 3, a plurality of spray water pipes 19 are installed on the secondary gasification chamber 2 from top to bottom, and the spray water pipe 19 is installed along the direction of how many A nozzle 18, and a spray water pipe 19 are installed on the outer wall of the water-cooled wall of the secondary gasification chamber 2 through a plurality of brackets 17. Other structures and methods are the same as those in Embodiment 1.

[0026] In this embodiment, the number of sprinkler water pipes 19 arranged from top to bottom is one to ...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 Describe this embodiment mode, a U-shaped coal gasification waste heat boiler with a spray cooling device described in this embodiment mode, the water supply system includes a water pump 11, a water inlet pipe 5 and a water outlet pipe 6, the water pump 11 is installed on the water inlet pipe 5, and the water inlet pipe The water pipe 5 communicates with the inlet end of the spray water pipe 19 , and the outlet end of the spray water pipe 19 communicates with the water outlet pipe 6 . Other structures and methods are the same as in the first embodiment.

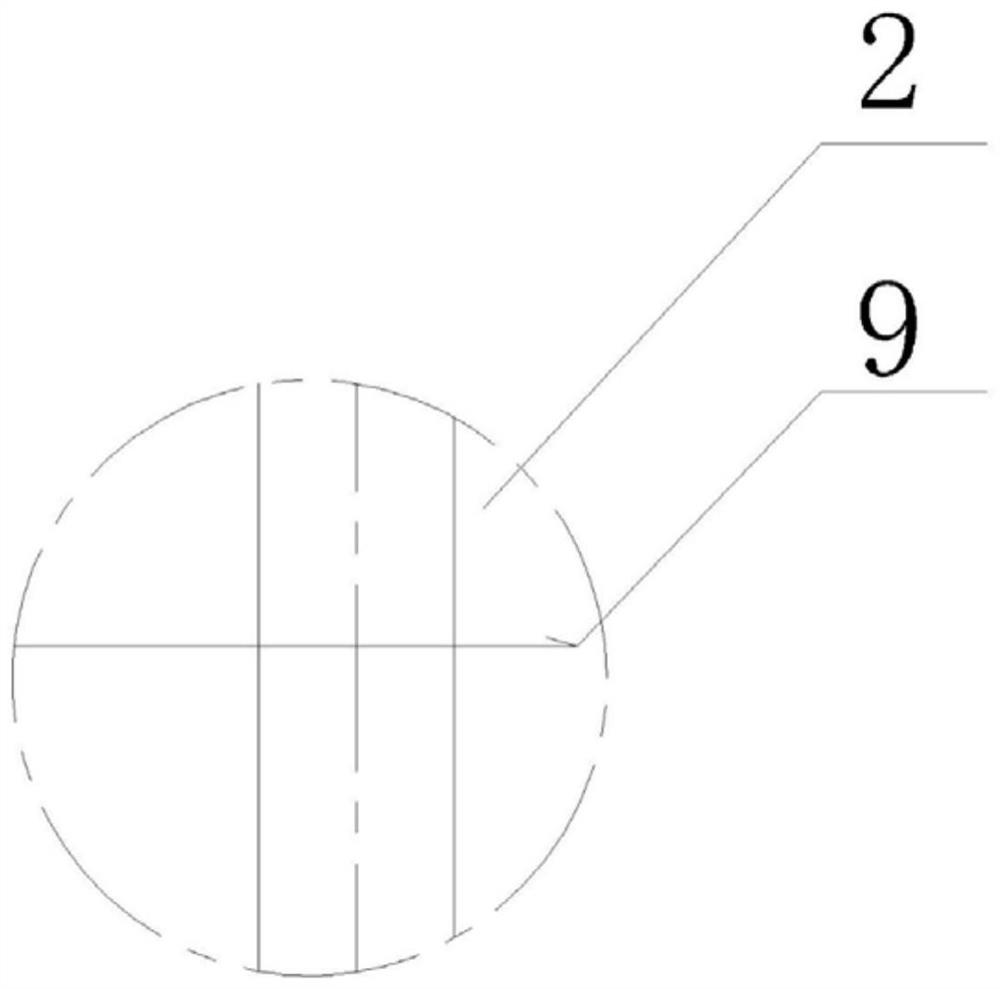

[0028] Specific implementation mode four: combination figure 1 and image 3Describe this embodiment, a U-shaped coal gasification waste heat boiler with a spray cooling device described in this embodiment, the control system includes a DCS controller 15, a flow meter 4, a plurality of high-temperature thermocouples 9, a plurality of medium-temperature thermocou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com