Textile dip dyeing device

A textile and dyeing liquid technology, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing, can solve the problems of unevenness, insufficient covering work speed, and low covering work efficiency, and achieve high work efficiency. Simple operation to complete different work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

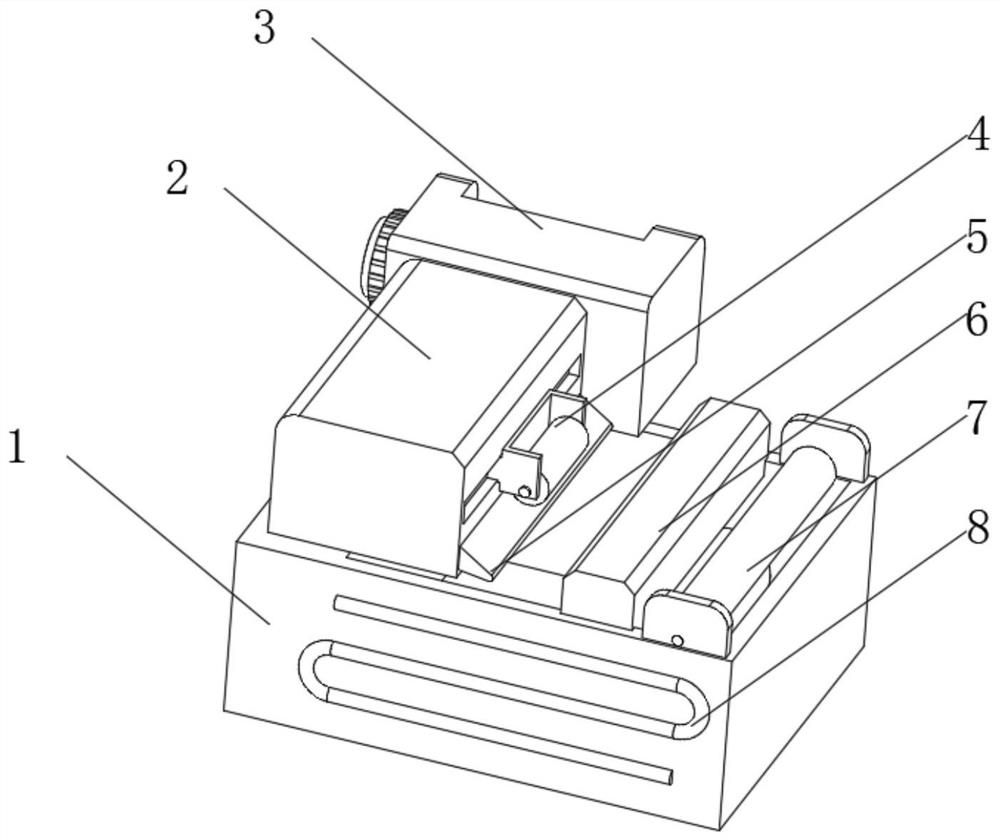

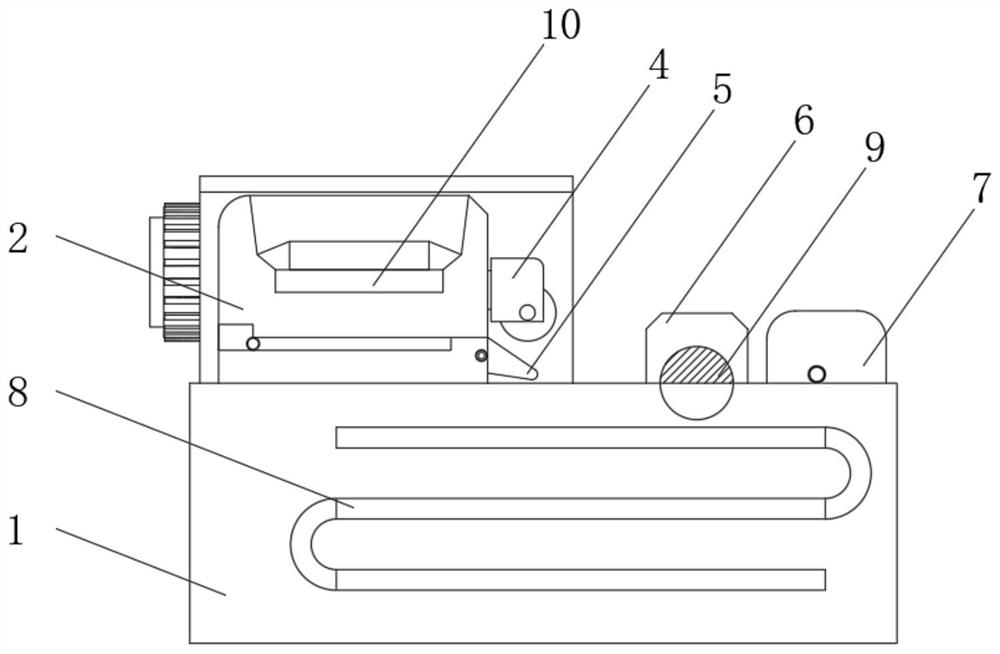

[0033] see Figure 1-2 , the present invention provides a technical solution: a textile exhaust dyeing device, including a printing and dyeing pool 1, a printing and dyeing post-treatment box 2 is arranged above the printing and dyeing pool 1, a control box 3 is arranged on the side of the printing and dyeing post-processing box 2, and a printing and dyeing post-processing box 2. A movable printing and dyeing auxiliary cylinder 4 is installed on the side above the printing and dyeing pool 1. A dipping and dyeing pool is provided inside the printing and dyeing pool 1. A dipping liquid mixing device 6 is arranged on the top of the printing and dyeing pool 1. The top of the printing and dyeing pool 1 is far away from the post-printing and dyeing treatment box 2. A feed roller 7 is installed on one side, and a feed adjustment plate 5 is installed below the feed port of the post-printing and dyeing treatment box 2. 5 is located under the movable printing and dyeing auxiliary cylind...

Embodiment example 2

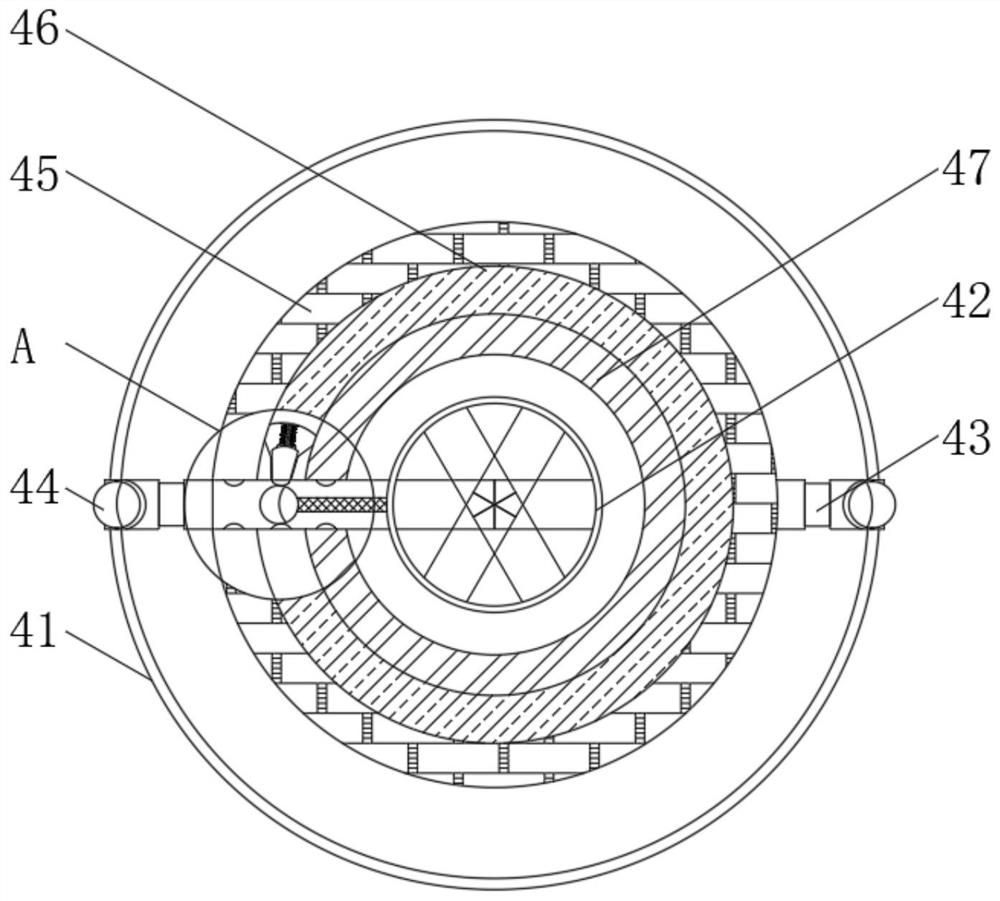

[0035] see Figure 1-5, on the basis of the implementation case 1, the present invention provides a technical solution: the movable printing and dyeing auxiliary cylinder 4 includes a cylinder body 41, a central shaft 42 is arranged inside the cylinder body 41, and an external storage liquid collar 45 is arranged inside the cylinder body 41. The middle storage liquid collar 46 and the storage liquid collar 47, the drum body 41 is provided with a through pipe 43 inside, the through pipe 43 runs through the external storage liquid collar 45, the middle storage liquid collar 46 and the memory liquid collar 47, and the through pipe The outer contact roller 44 is installed on the outer side of 43, and the inside of the movable printing and dyeing auxiliary cylinder 4 adopts a plurality of liquid storage inner collars, and different solvents are added inside. When the movable printing and dyeing auxiliary cylinder 4 has different rotation speeds, the device will produce With differe...

Embodiment example 3

[0040] see Figure 1-7 , on the basis of the implementation case 1 and the implementation case 2, the present invention provides a technical solution: the mixing mechanism 9 includes a side mounting seat 91, and a central shaft 92 and an outer spiral mixing frame 93 are installed between the side mounting seats 91 , the central axis 92 is located at the inner side of the outer helical wire mixing frame 93, a chute mounting frame is installed outside the central axis 92, an outer movable frame 94 is installed on the outer side of the chute mounting frame, and a centrifugal connector 96 is installed between the outer movable frames 94. Elastic buffer rods 95 are installed between the movable frames 94 .

[0041] The outer spiral wire mixing frame 93 is provided with three groups, and the gap between the three groups of outer spiral wire mixing racks 93 is smaller than the gap between the outer spiral wire mixing frame 93's own helix, and the mixing mechanism 9 of the device is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com