Device and method for accurately measuring magnetostriction micro-deformation

A technology of magnetostriction and magnetostrictive materials, applied in the field of optical sensing, can solve the problems of high cost of auxiliary testing instruments, measurement accuracy and accuracy are susceptible to external interference, etc., to improve measurement accuracy and rapidity, measure The process steps are simple and the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

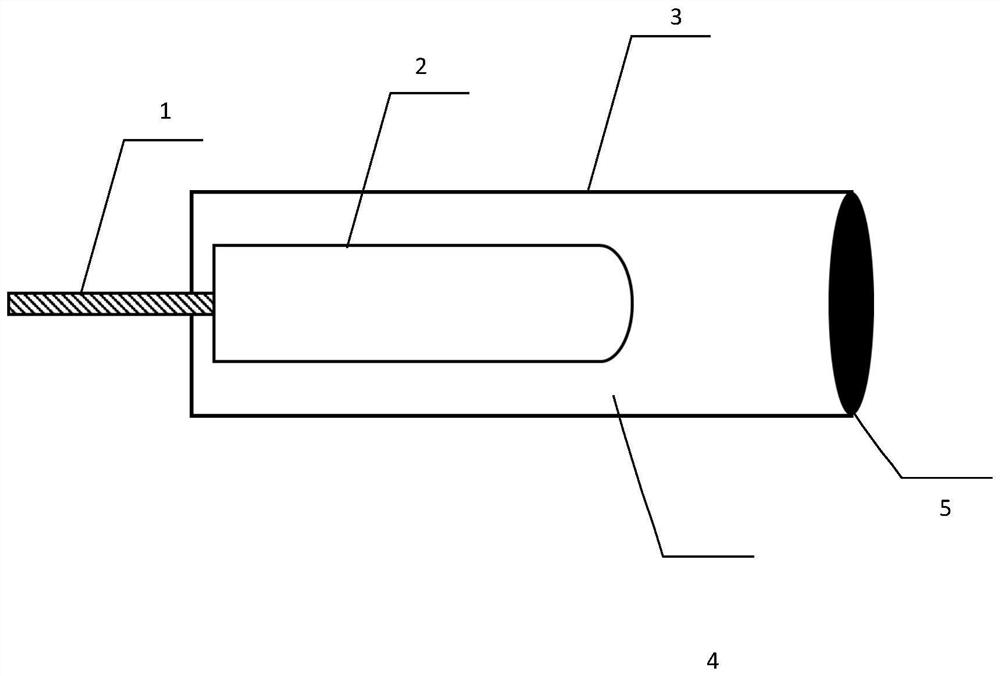

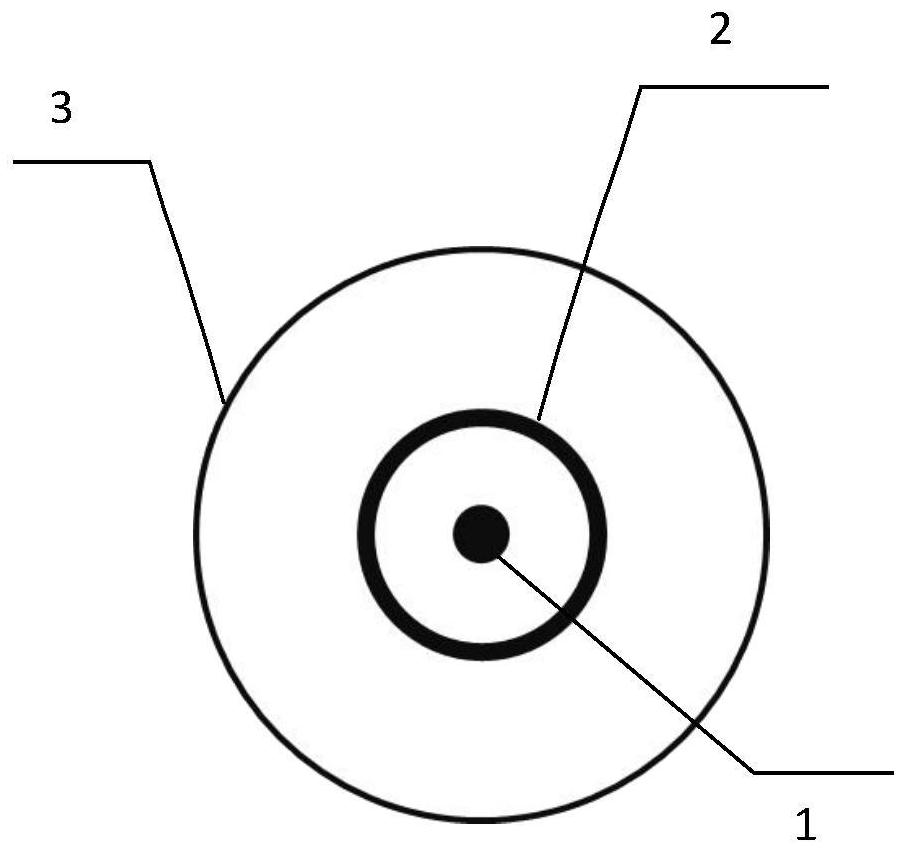

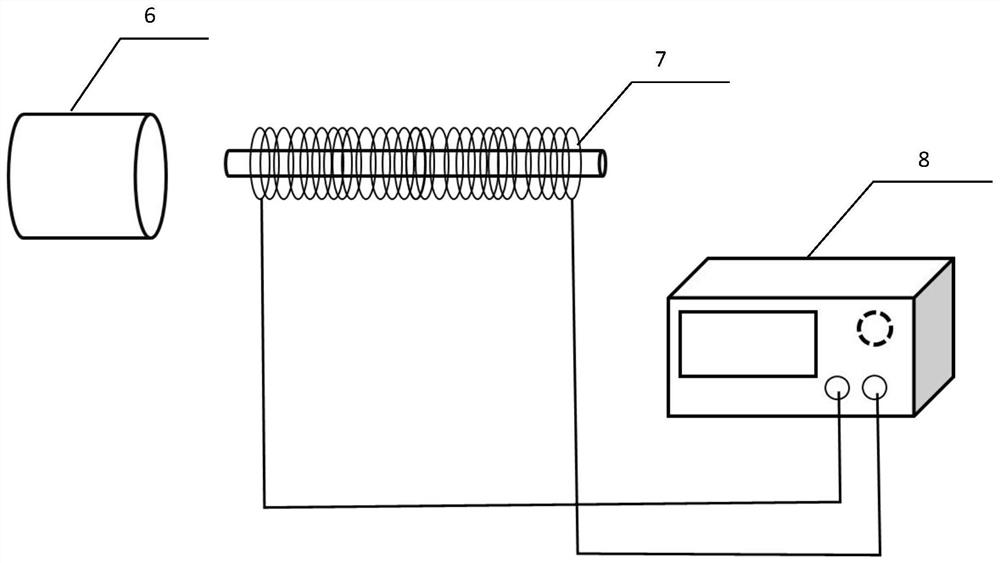

[0033] Referring to Fig. 1(a) and Fig. 1(b), a device for measuring magnetostrictive micro-deformation includes an optical fiber 1, and one end of the optical fiber 1 is inserted into the tail of the fiber ferrule 2; the fiber ferrule 2 is located at The left end of the inner cavity of the stainless steel tube 3; the right port of the stainless steel tube 3 is provided with a Terfenol-D metal sheet. Insert the optical fiber into the tail of the ceramic ferrule, and construct a FRP cavity with air as the medium with one end face of the ceramic ferrule. The constructed FRP cavity includes two reflection surfaces, one reflection surface is the end surface of the ceramic A reflective surface is a corresponding thin sheet of magnetostrictive Terfenol-D material. When receiving the action of a magnetic field, the sheet will be slightly deformed alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com