Optical fiber cable with long service life

A fiber optic cable, life-span technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of the internal optical fiber not playing a good role in protection, the popularity of optical fiber, low maintenance cost, easy to be bitten by animals, etc. Good protection effect, good fire protection effect, good effect of preventing animal bites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

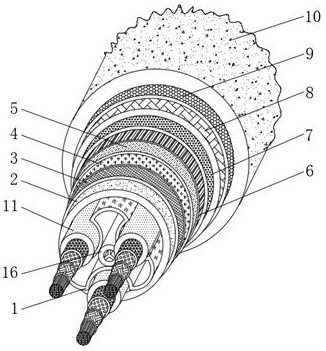

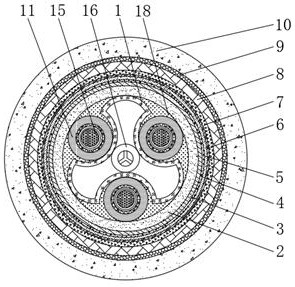

[0030] Such as Figure 1-7As shown, the present invention provides a technical solution: a fiber optic cable with high service life, including a bracket 1, the material of the bracket 1 is a tough steel plate, and the difference between the diameter of the inner wall of the limiting groove 19 and the surface diameter of the deformable layer 11 3 mm, by setting the bracket 1, the bracket 1 can maintain a stable protection for the optical fiber 15 during use, and at the same time can maintain a stable supporting effect. The bracket 1 is a tough steel plate, so that it can maintain the It has good toughness and can be reset in time after the stress is over. By setting the limit groove 19, the limit groove 19 can protect the optical fiber 15 very well, and at the same time, it can spread the pressure evenly and make the pressure change. form a clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com