A kind of stepped current charging method that prevents lithium-ion battery negative electrode from decomposing lithium

A technology of lithium ion battery and charging method, which is applied in the direction of charging/discharging secondary battery, secondary battery, and secondary battery repair/maintenance, etc. and other problems, to achieve the effect of preventing lithium precipitation in the negative electrode, improving charging efficiency, and reducing safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

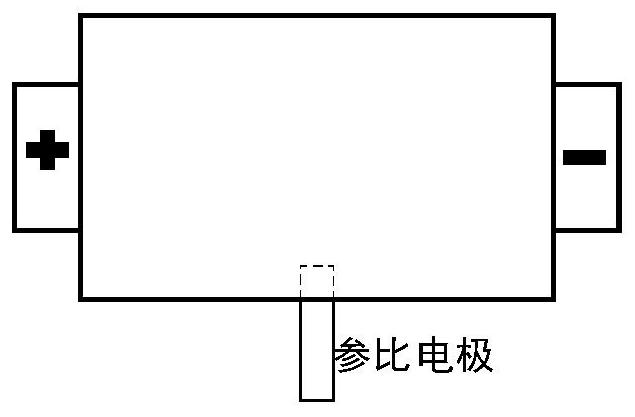

[0033] S1, figure 1 A schematic diagram of a three-electrode cell fabricated from a commercial cell is shown. Perform electrochemical impedance spectroscopy and capacity increment curve tests on three-electrode batteries and commercial batteries: the electrochemical impedance spectrum test frequency range is 10 millihertz to 10 kilohertz, and the sinusoidal AC voltage amplitude is set to 5 mV; the capacity increment curve test set Charge at 0.05C to 4.2V, let it stand for 1 hour, and discharge at 0.05C to 2.5V to verify the effectiveness of the reference electrode. The electrochemical model established by using a three-electrode battery is more in line with the performance characteristics of commercial batteries;

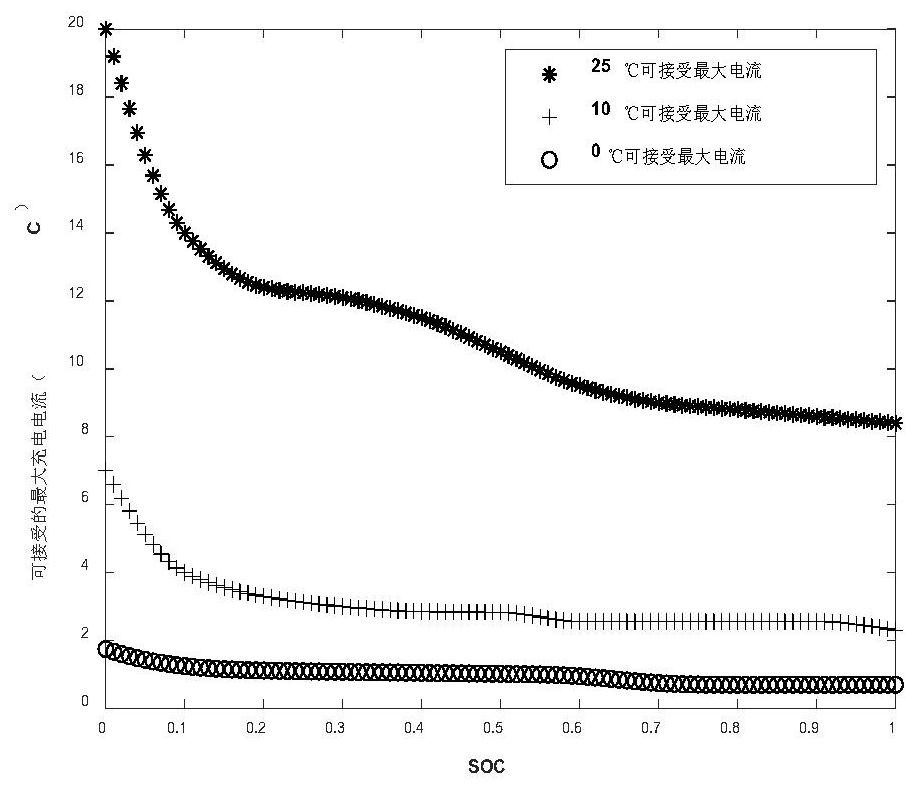

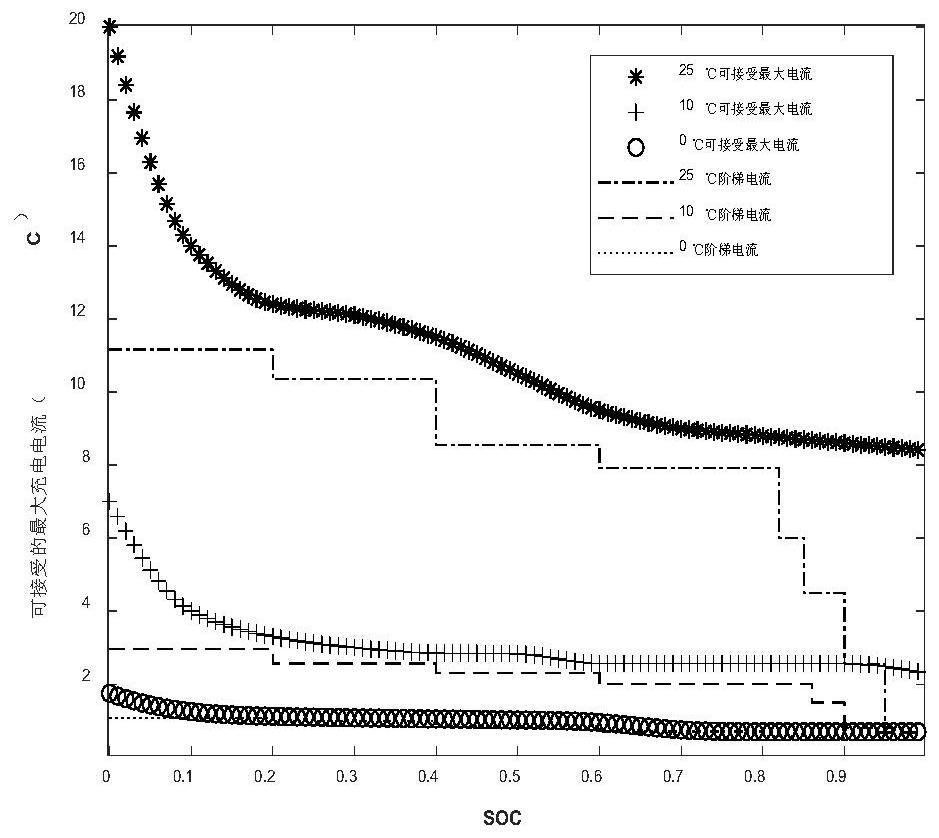

[0034] S2. Test the rated capacity of the three-electrode battery at a room temperature of 25°C. The three-electrode battery is placed in an incu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com