Electrical contacting and method for producing an electrical contacting

A technology of electrical contacts and contacts, which is applied in the manufacture of microstructure devices, circuits, electrical components, etc., can solve problems such as high resistance, and achieve the effects of high conductivity, low cost, and small process consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

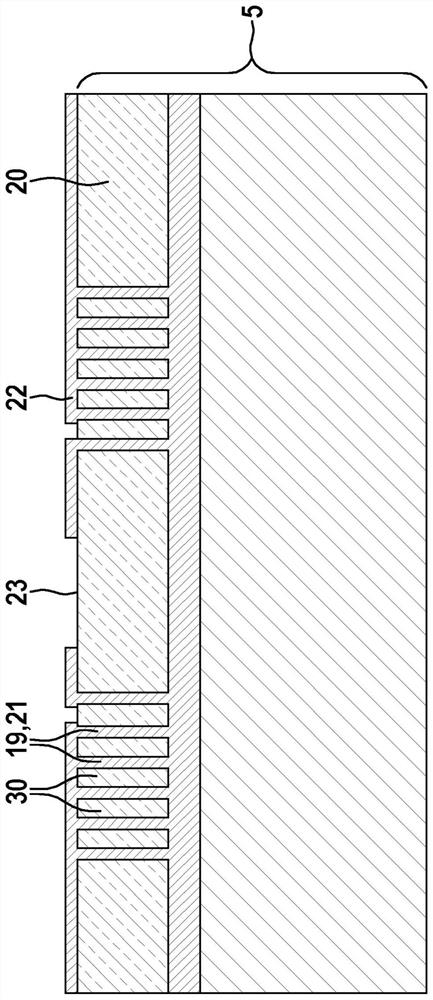

[0050] exist figure 1 A schematic illustration of the method for producing an electrical contact 1 according to an embodiment of the invention after the third preliminary step is shown in . Structures 19 have already been created (dug out) in the silicon layer 20 of the SOI wafer 5 or SOI chip 5 before the second preliminary step. The individual components of the microelectromechanical component 30 are delimited by means of the structure 19 . In a second preliminary step a third insulator 21 has already been deposited in the structure 19 and at the same time a third insulator layer 22 is formed over the silicon layer 20 . Preferably, the third insulator layer 22 and the third insulator 21 respectively consist of the same oxide. In a third pre-step, the insulator layer 22 has been removed in the second contact region 23 .

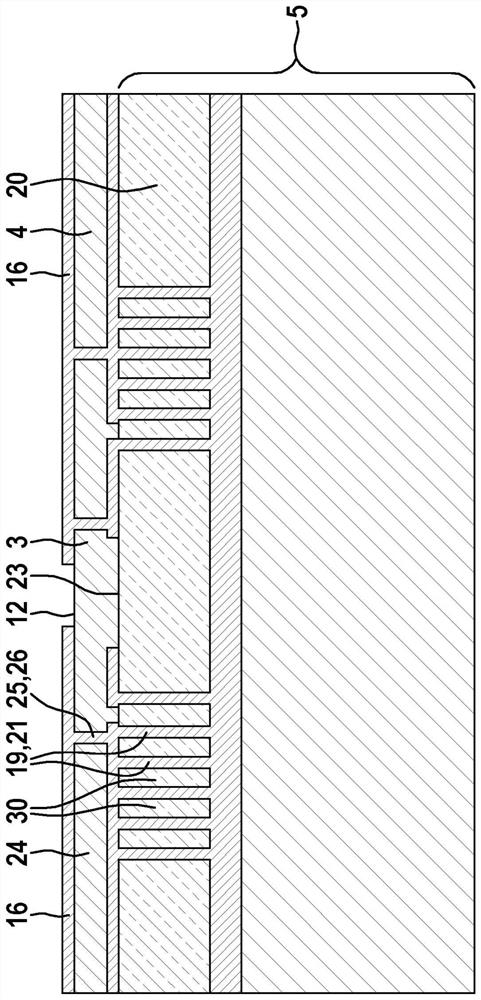

[0051] exist figure 2 A schematic illustration of the method for producing an electrical contact 1 according to an embodiment of the invention after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com