Self-balancing type metal plate shearing device

A metal sheet and shearing device technology, which is applied to shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the requirements for reducing the strength, aesthetics and size of the edge area of metal sheets, and low processing efficiency, etc. problems, to achieve the effect of ensuring the continuity of reinforcement, reducing the difficulty of shearing, and not prone to serious deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

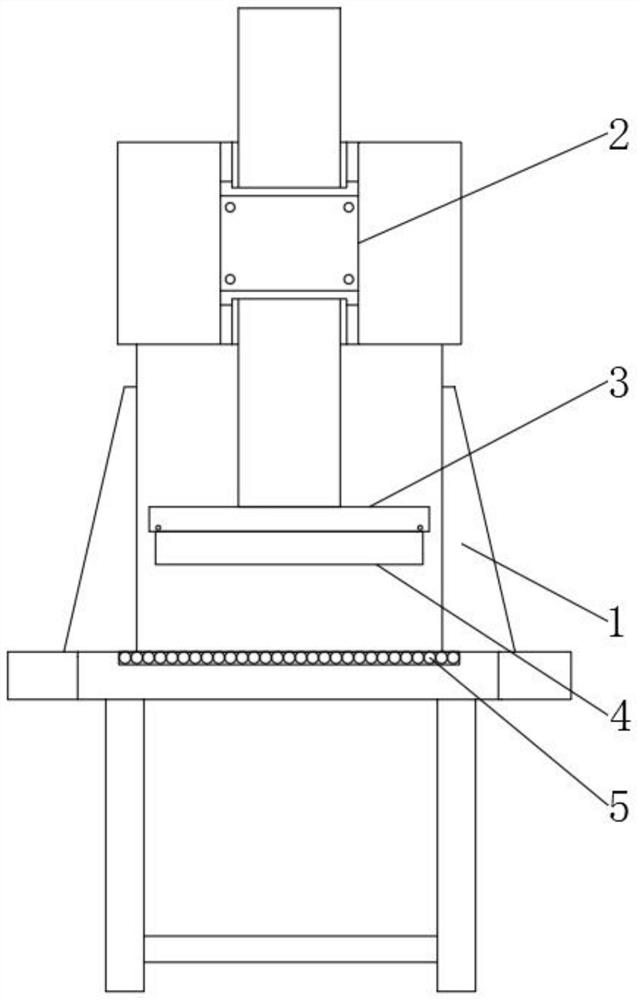

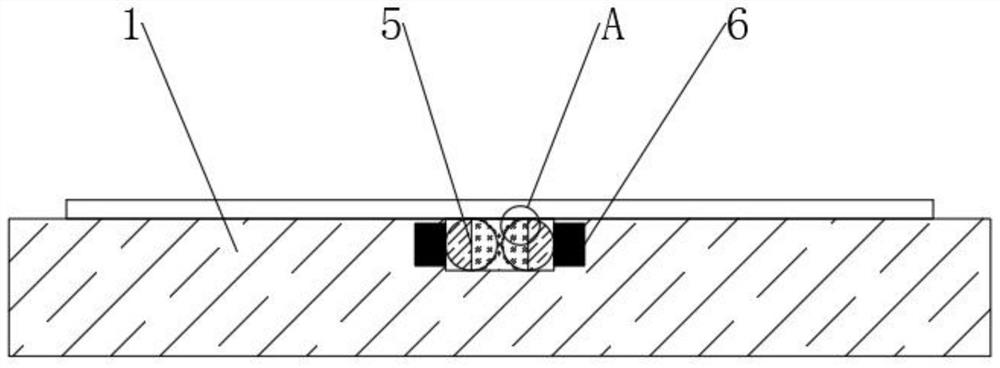

[0044] see Figure 1-2 , a self-balancing sheet metal shearing device, comprising a machine tool body 1, a hydraulic cylinder 2 is installed on the upper end of the machine tool body 1, a cutter head 3 is installed on the output end of the hydraulic cylinder 2, a blade 4 is installed on the lower end of the cutter head 3, the machine tool body The working surface of 1 is provided with a knife groove, and two rows of closely distributed self-supporting balls 5 are connected in the knife groove, and a knife insertion gap is left between the two rows of self-supporting balls 5, which are placed in the two side walls of the knife groove Electromagnets 6 are all embedded.

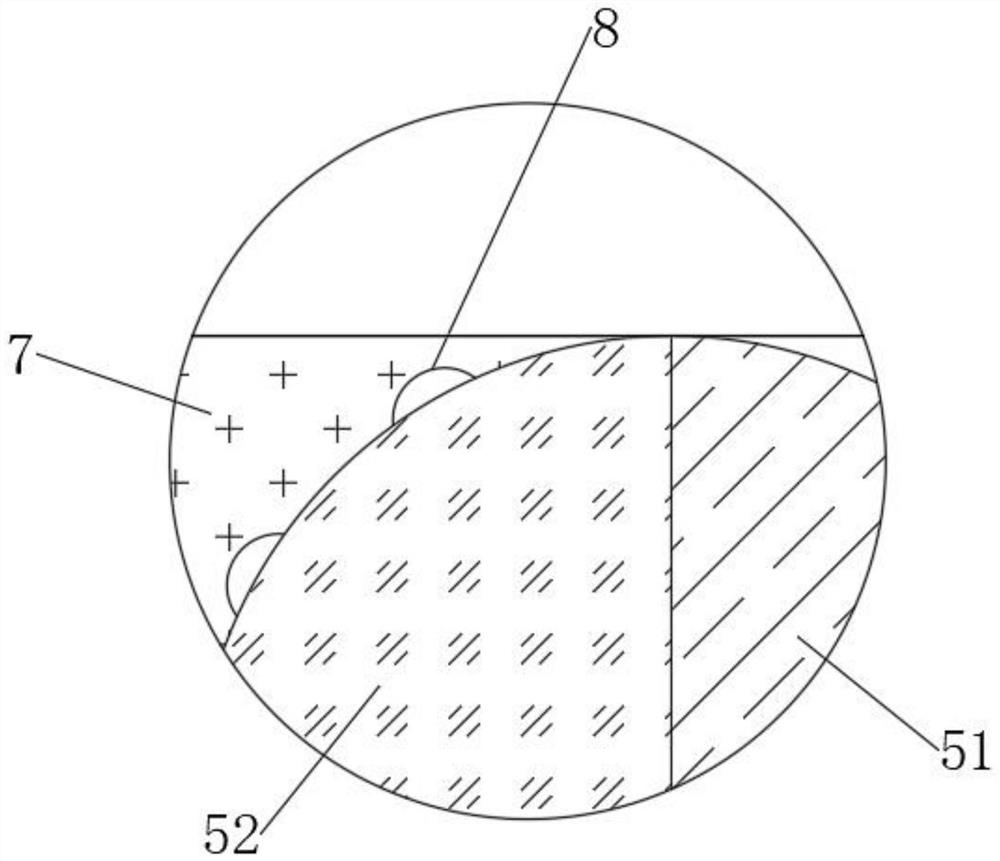

[0045] see Figure 4 , the self-supporting ball 5 includes a symmetrically connected rigid hemisphere 51 and an elastic hemisphere 52, and the rigid hemisphere 51 is connected to the side wall of the sipe, the outer end of the elastic hemisphere 52 is connected with a plurality of evenly distributed trigger pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com