Motor driven drum type parking brake

A parking brake and motor-driven technology, which is applied in the direction of mechanically driven drum brakes, electric components, brake actuators, etc., can solve the problems of complex structure and slow brake response, and achieve the effect of compact and reasonable structure and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

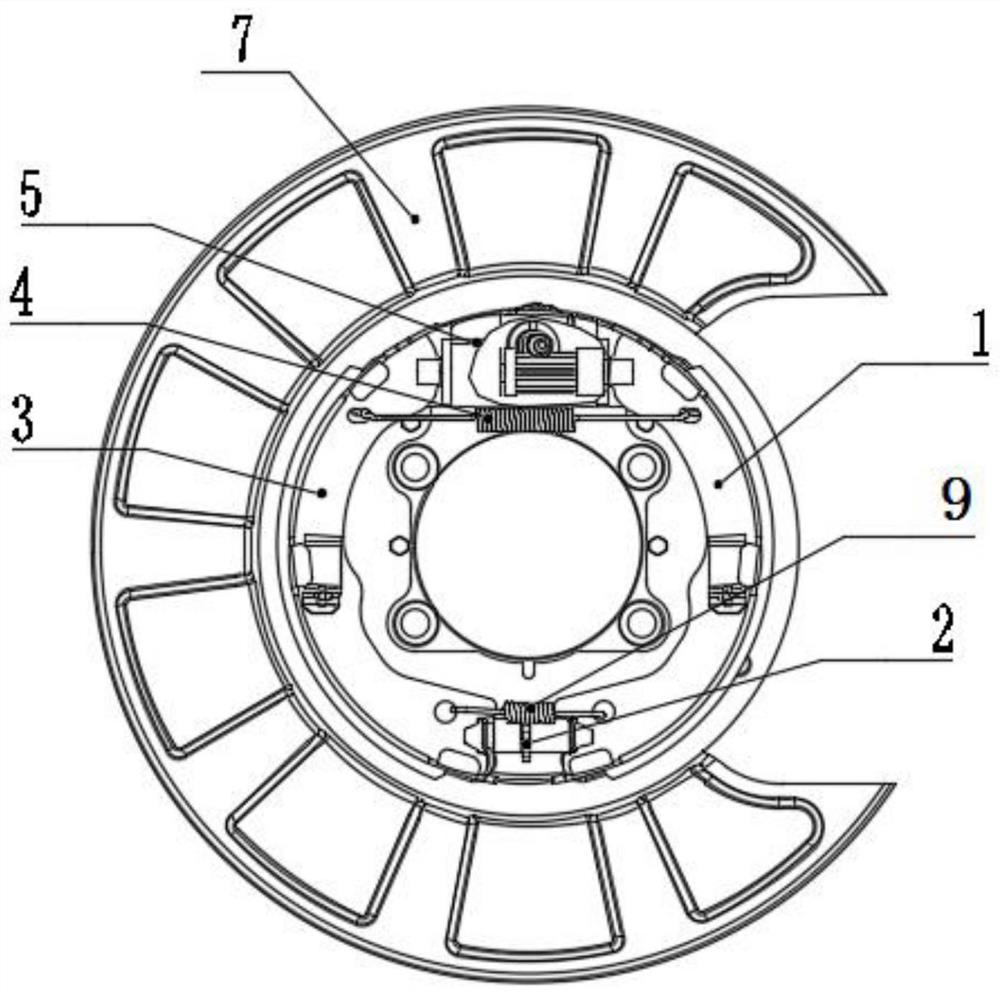

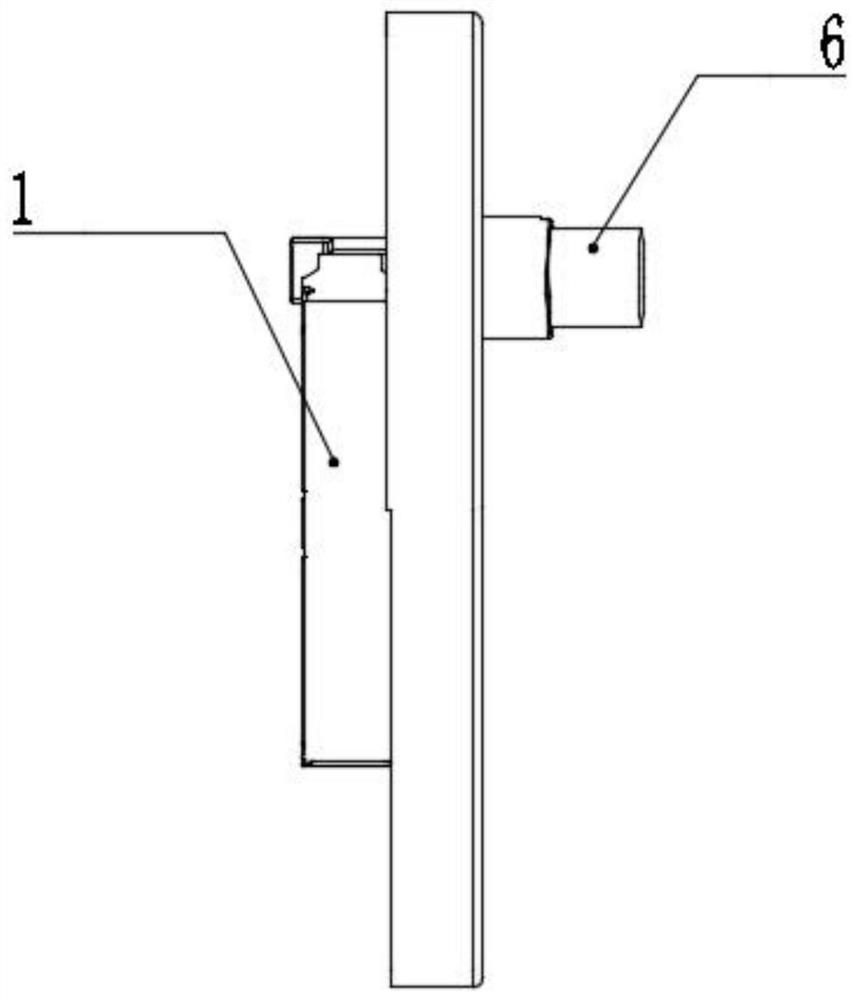

[0022] Such as Figure 1-4 As shown, a motor-driven drum parking brake includes a front brake shoe 1 installed on a brake base plate 7, an adjustment ratchet 2 and a rear brake shoe 3, and the front brake shoe 1 and the rear brake shoe 3 is connected with an upper return spring 4, the upper ends of the front brake shoe 1 and the rear brake shoe 3 are hinged on the shoe support pin, and the lower ends of the front brake shoe 1 and the rear brake shoe 3 are connected with the gap adjustment The adjusting ratchet 2 is connected to the lower return spring 9; it also includes a transmission mechanism assembly 5, and the transmission mechanism assembly 5 is connected to the front brake shoe 1 and the rear brake shoe 3 through a supporting piston 502.

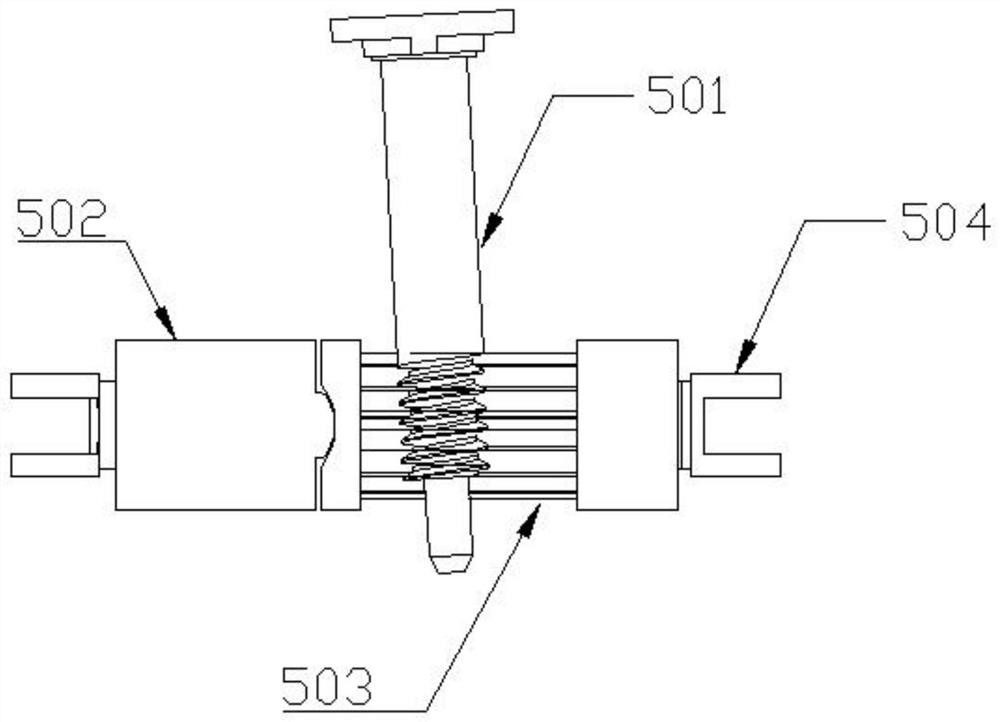

[0023] Such as image 3 , 4 As shown, the transmission mechanism assembly 5 includes a motor reduction mechanism, a worm 501, a worm wheel 503 and a screw 504, the output shaft end of the motor reduction mechanism is connected to on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com