Optimized operation and maintenance system of air compressor

An air compressor, operation and maintenance system technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of reduced operating performance, difficult staffing on duty, poor fault response ability, etc., to improve the level of specialization and improve operation Dimension Response Efficiency and Cost Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

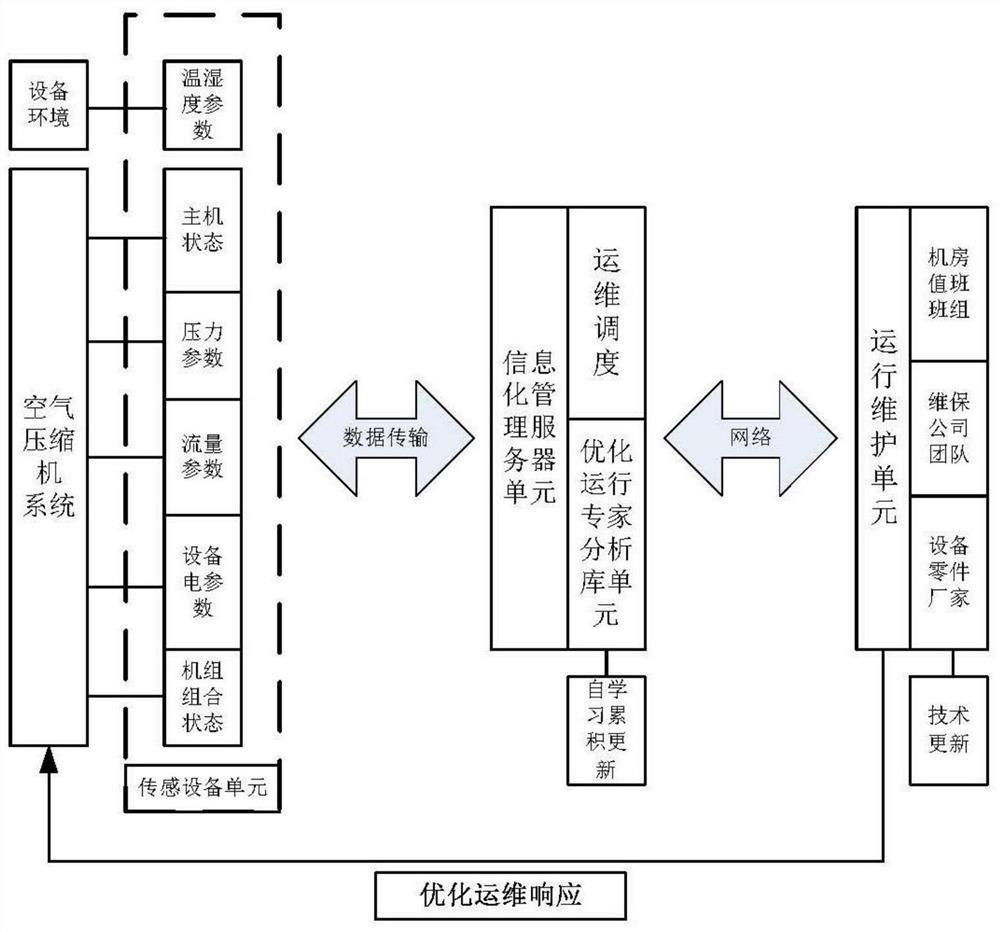

[0012] Such as figure 1 As shown, the sensor equipment unit collects and transmits the parameter data information of the air compressor system to the information management server, and uses the optimized operation expert analysis library unit equipped with software and the operation and maintenance scheduling function as the execution basis of the operation and maintenance unit to realize System operation and maintenance information management.

[0013] The sensing device unit includes various types of sensors such as temperature and humidity, flow, pressure and energy consumption, which are configured on demand and converted into transmissible digital signals and sent to the information management server unit.

[0014] The optimization operation expert analysis library unit can provide professional advice for the air compressor system optimization operation status management at any time, and the optimization operation expert analysis library can expand expert experience at an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com